SECTION 6 − MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

| n = Check | ~ = Clean | l = Replace |

| Reference |

Every |

|

|

|

| Section |

3 |

|

|

|

| |

Months |

|

|

|

|

|

| l Unreadable Labels | ~ Weld Terminals | nl Weld Cable | nl Motor Brush | |

|

|

|

|

| Section |

|

|

|

|

| |

| n | n Gas Hose and Fittings | n Gun Cable |

| |

Every |

|

|

|

| Section |

6 |

|

|

|

| |

Months | Or |

|

|

|

|

| ~ Inside Unit | ~ Drive Rolls |

|

|

|

|

|

| |||

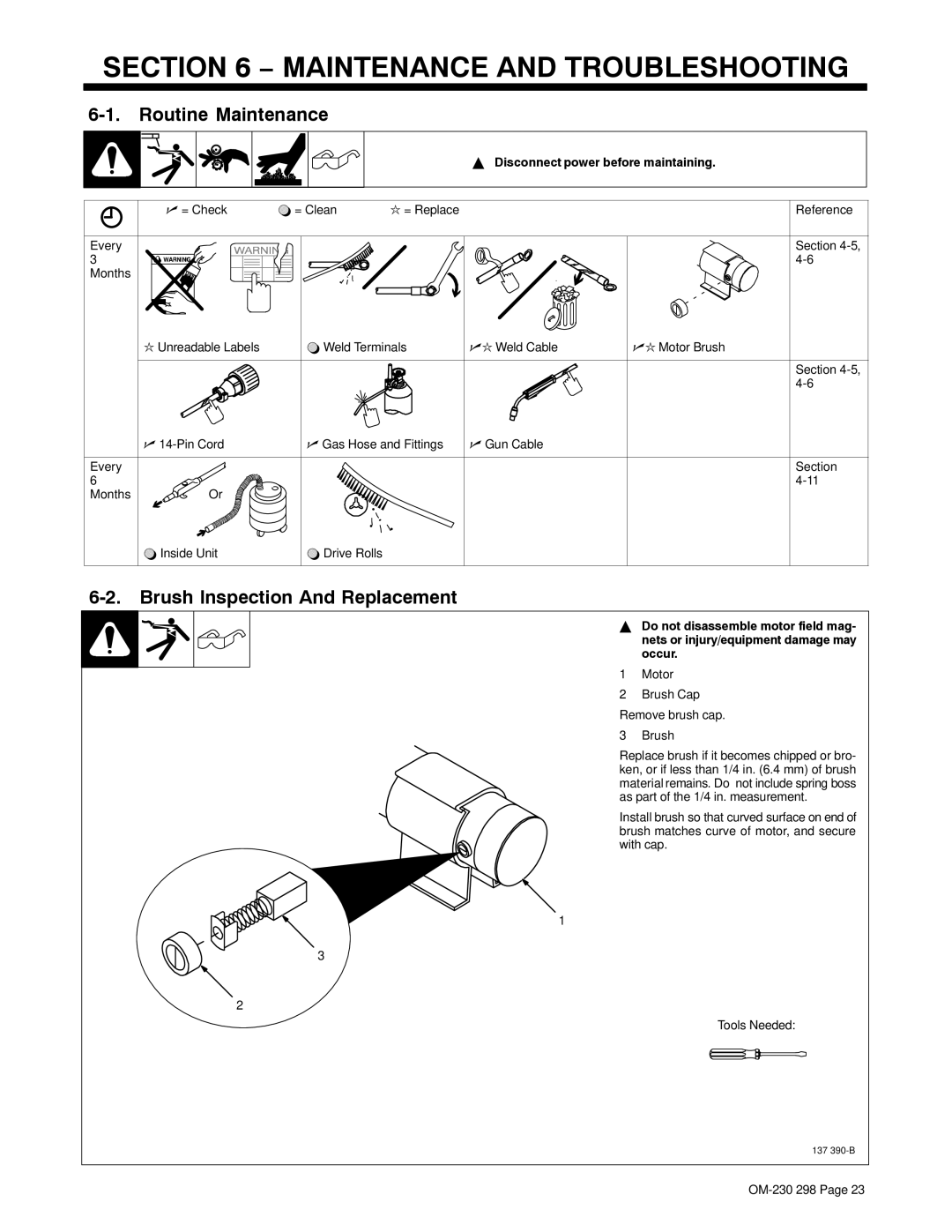

Y Do not disassemble motor field mag- nets or injury/equipment damage may occur.

1 Motor

2 Brush Cap Remove brush cap.

3 Brush

Replace brush if it becomes chipped or bro- ken, or if less than 1/4 in. (6.4 mm) of brush material remains. Do not include spring boss as part of the 1/4 in. measurement.

Install brush so that curved surface on end of brush matches curve of motor, and secure with cap.

1

3

2

Tools Needed:

137