6-3. Diagnostics

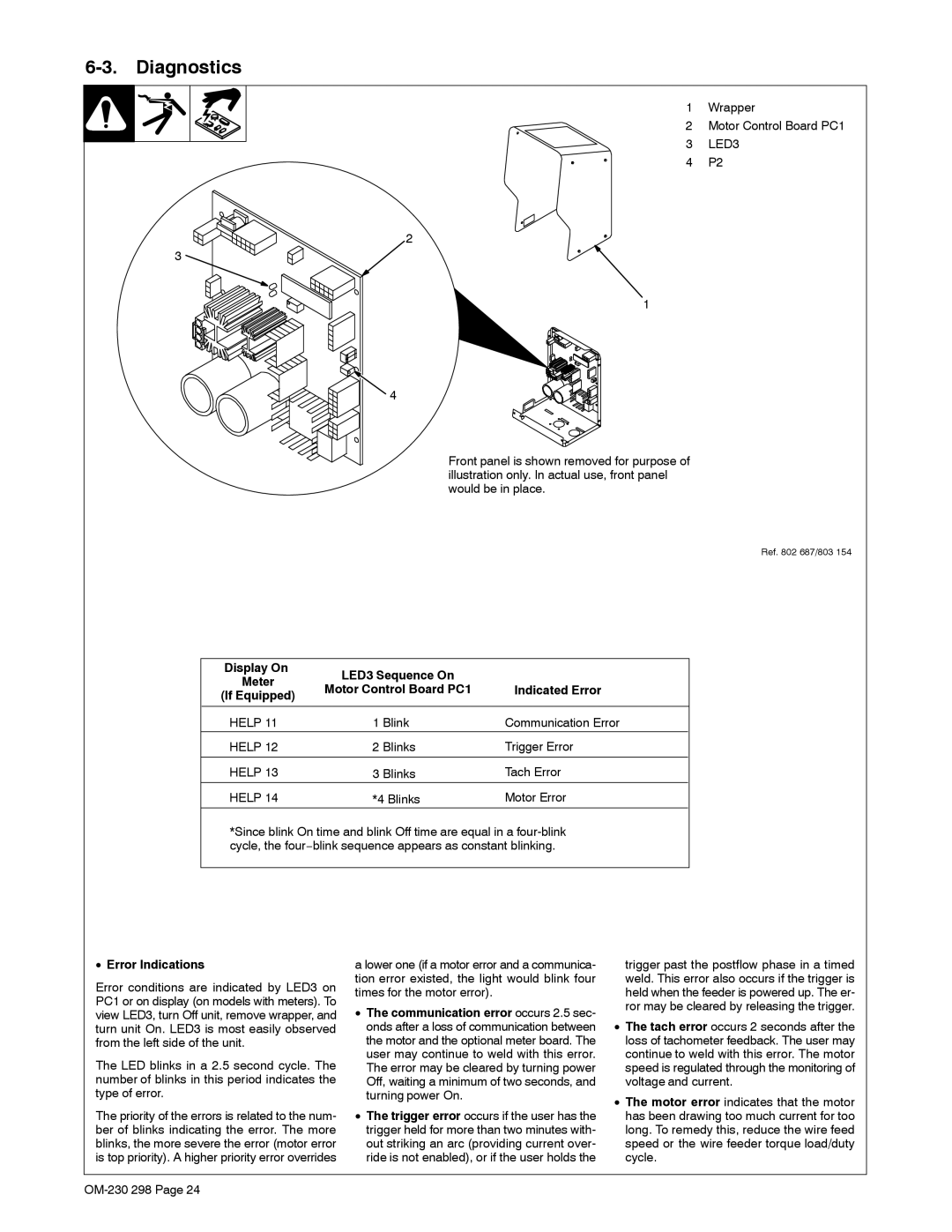

1 Wrapper

2 Motor Control Board PC1

3 LED3

4 P2

2

3

1

![]() 4

4

Front panel is shown removed for purpose of illustration only. In actual use, front panel would be in place.

Ref. 802 687/803 154

Display On | LED3 Sequence On |

|

| ||

Meter |

|

| |||

Motor Control Board PC1 | Indicated Error | ||||

(If Equipped) | |||||

|

|

|

| ||

|

|

|

|

| |

HELP 11 | 1 | Blink | Communication Error |

| |

HELP 12 | 2 | Blinks | Trigger Error | ||

|

|

|

|

| |

HELP 13 | 3 | Blinks | Tach Error |

| |

HELP 14 | *4 Blinks | Motor Error | |||

*Since blink On time and blink Off time are equal in a

•Error Indications

Error conditions are indicated by LED3 on PC1 or on display (on models with meters). To view LED3, turn Off unit, remove wrapper, and turn unit On. LED3 is most easily observed from the left side of the unit.

The LED blinks in a 2.5 second cycle. The number of blinks in this period indicates the type of error.

The priority of the errors is related to the num- ber of blinks indicating the error. The more blinks, the more severe the error (motor error is top priority). A higher priority error overrides

a lower one (if a motor error and a communica- tion error existed, the light would blink four times for the motor error).

•The communication error occurs 2.5 sec- onds after a loss of communication between the motor and the optional meter board. The user may continue to weld with this error. The error may be cleared by turning power Off, waiting a minimum of two seconds, and turning power On.

•The trigger error occurs if the user has the trigger held for more than two minutes with- out striking an arc (providing current over- ride is not enabled), or if the user holds the

trigger past the postflow phase in a timed weld. This error also occurs if the trigger is held when the feeder is powered up. The er- ror may be cleared by releasing the trigger.

•The tach error occurs 2 seconds after the loss of tachometer feedback. The user may continue to weld with this error. The motor speed is regulated through the monitoring of voltage and current.

•The motor error indicates that the motor has been drawing too much current for too long. To remedy this, reduce the wire feed speed or the wire feeder torque load/duty cycle.