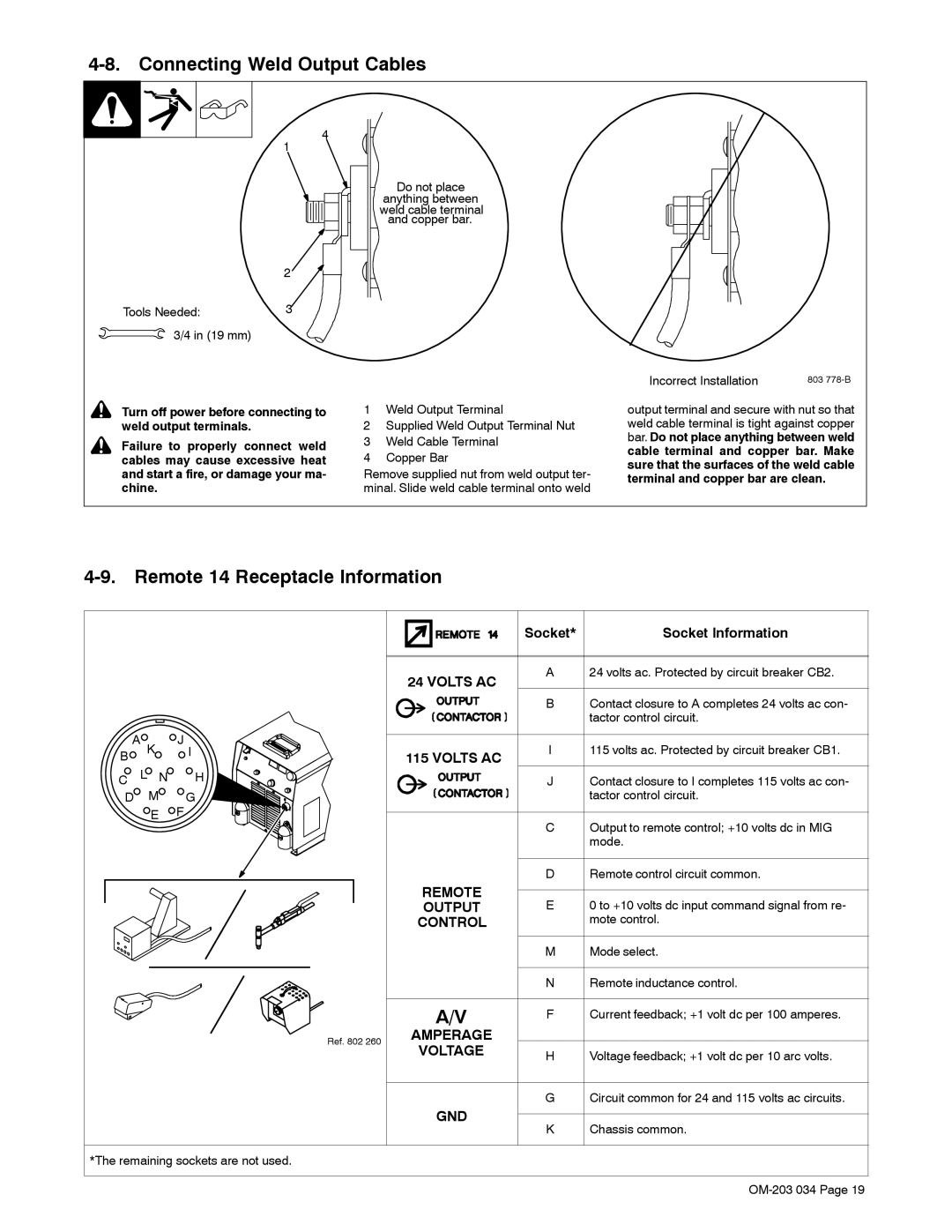

4-8. Connecting Weld Output Cables

| 4 |

|

|

| 1 |

|

|

|

|

| Do not place |

|

|

| anything between |

|

|

| weld cable terminal |

|

|

| and copper bar. |

| 2 |

|

|

Tools Needed: | 3 |

|

|

3/4 in (19 mm) |

|

|

|

! Turn off power before connecting to | 1 | Weld Output Terminal | |

weld output terminals. |

| 2 | Supplied Weld Output Terminal Nut |

! Failure to properly connect weld | 3 | Weld Cable Terminal | |

cables may cause excessive heat | 4 | Copper Bar | |

and start a fire, or damage your ma- | Remove supplied nut from weld output ter- | ||

chine. |

| minal. Slide weld cable terminal onto weld | |

Incorrect Installation | 803 |

output terminal and secure with nut so that weld cable terminal is tight against copper bar. Do not place anything between weld cable terminal and copper bar. Make sure that the surfaces of the weld cable terminal and copper bar are clean.

4-9. Remote 14 Receptacle Information

A K | J I | |

B |

|

|

C | L N | H |

D | M | G |

| E | F |

Ref. 802 260

| Socket* | Socket Information |

24 VOLTS AC | A | 24 volts ac. Protected by circuit breaker CB2. |

|

| |

| B | Contact closure to A completes 24 volts ac con- |

|

| tactor control circuit. |

115 VOLTS AC | I | 115 volts ac. Protected by circuit breaker CB1. |

|

| |

| J | Contact closure to I completes 115 volts ac con- |

|

| tactor control circuit. |

| C | Output to remote control; +10 volts dc in MIG |

|

| mode. |

| D | Remote control circuit common. |

REMOTE | E | 0 to +10 volts dc input command signal from re- |

OUTPUT | ||

CONTROL |

| mote control. |

| M | Mode select. |

| N | Remote inductance control. |

A/V | F | Current feedback; +1 volt dc per 100 amperes. |

AMPERAGE |

|

|

VOLTAGE | H | Voltage feedback; +1 volt dc per 10 arc volts. |

| ||

| G | Circuit common for 24 and 115 volts ac circuits. |

GND | K | Chassis common. |

|

*The remaining sockets are not used.