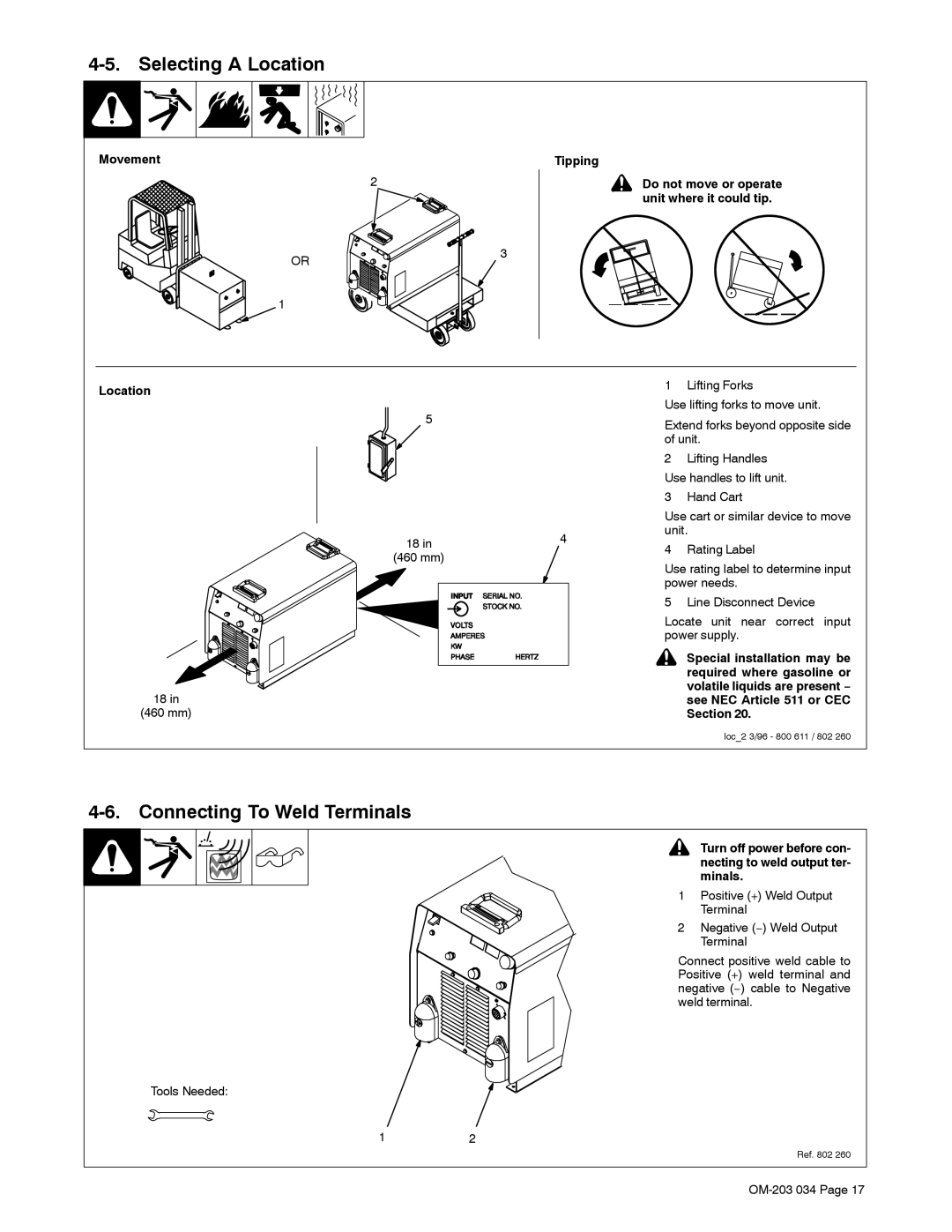

4-5. Selecting A Location

Movement

| 2 |

OR | 3 |

|

1

Tipping

! |

Do not move or operate unit where it could tip.

Location |

|

| 1 | Lifting Forks |

|

| Use lifting forks to move unit. | ||

| 5 |

| ||

|

| Extend forks beyond opposite side | ||

|

|

| ||

|

|

| of unit. | |

|

|

| 2 | Lifting Handles |

|

|

| Use handles to lift unit. | |

|

|

| 3 | Hand Cart |

|

|

| Use cart or similar device to move | |

| 18 in | 4 | unit. | |

| 4 | Rating Label | ||

|

| |||

| (460 mm) |

| ||

|

| Use rating label to determine input | ||

|

|

| ||

|

|

| power needs. | |

|

|

| 5 | Line Disconnect Device |

|

|

| Locate unit near correct input | |

|

|

| power supply. | |

! |

18in

(460 mm)

Special installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20.

loc_2 3/96 - 800 611 / 802 260

4-6. Connecting To Weld Terminals

! Turn off power before con- necting to weld output ter- minals.

1 Positive (+) Weld Output Terminal

2 Negative (−) Weld Output Terminal

Connect positive weld cable to Positive (+) weld terminal and negative (−) cable to Negative weld terminal.

Tools Needed:

12

Ref. 802 260