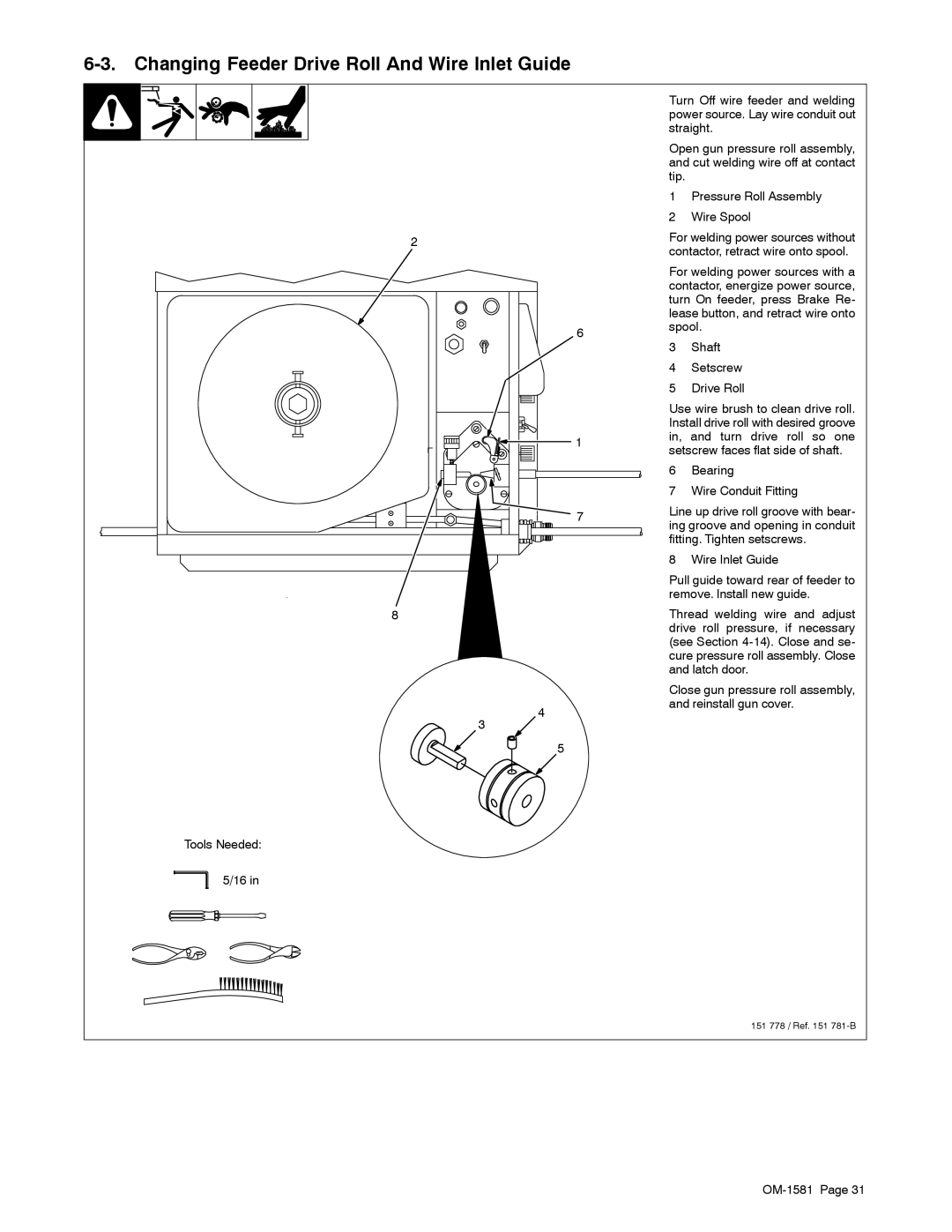

6-3. Changing Feeder Drive Roll And Wire Inlet Guide

Turn Off wire feeder and welding power source. Lay wire conduit out straight.

Open gun pressure roll assembly, and cut welding wire off at contact tip.

1Pressure Roll Assembly

2Wire Spool

2

8

3

Tools Needed:

5/16 in

6

1

7

4

5

For welding power sources without contactor, retract wire onto spool.

For welding power sources with a contactor, energize power source, turn On feeder, press Brake Re- lease button, and retract wire onto spool.

3Shaft

4Setscrew

5Drive Roll

Use wire brush to clean drive roll. Install drive roll with desired groove in, and turn drive roll so one setscrew faces flat side of shaft.

6Bearing

7Wire Conduit Fitting

Line up drive roll groove with bear- ing groove and opening in conduit fitting. Tighten setscrews.

8 Wire Inlet Guide

Pull guide toward rear of feeder to remove. Install new guide.

Thread welding wire and adjust drive roll pressure, if necessary (see Section

Close gun pressure roll assembly, and reinstall gun cover.

151 778 / Ref. 151