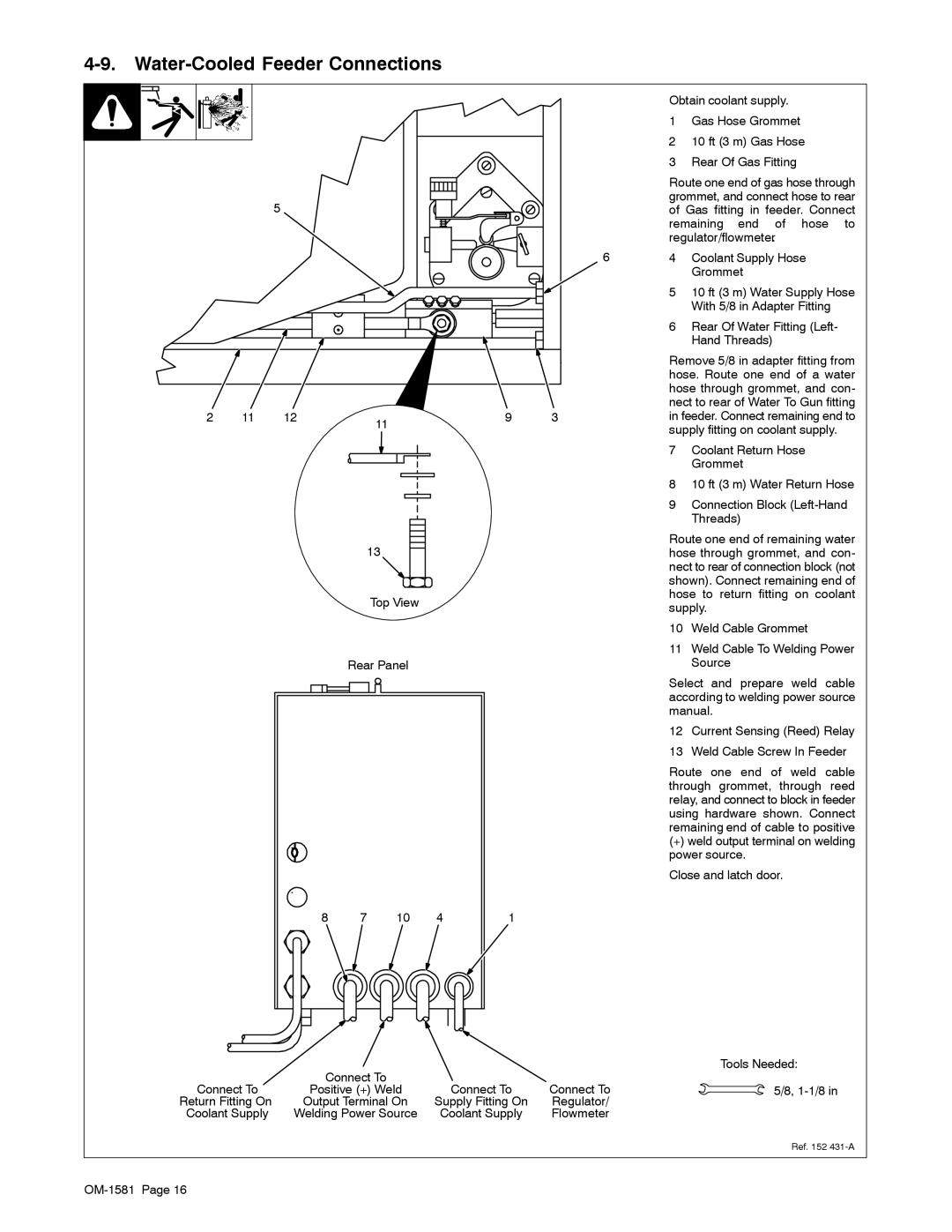

4-9. Water-Cooled Feeder Connections

5

6

2 | 11 | 12 | 11 | 9 | 3 |

|

|

|

|

|

13

Top View

Rear Panel

8 | 7 | 10 | 4 | 1 |

Connect To | Connect To | Connect To | Connect To |

Positive (+) Weld | |||

Return Fitting On | Output Terminal On | Supply Fitting On | Regulator/ |

Coolant Supply | Welding Power Source | Coolant Supply | Flowmeter |

Obtain coolant supply.

1Gas Hose Grommet

210 ft (3 m) Gas Hose

3Rear Of Gas Fitting

Route one end of gas hose through grommet, and connect hose to rear of Gas fitting in feeder. Connect remaining end of hose to regulator/flowmeter.

4Coolant Supply Hose Grommet

510 ft (3 m) Water Supply Hose With 5/8 in Adapter Fitting

6Rear Of Water Fitting (Left- Hand Threads)

Remove 5/8 in adapter fitting from hose. Route one end of a water hose through grommet, and con- nect to rear of Water To Gun fitting in feeder. Connect remaining end to supply fitting on coolant supply.

7Coolant Return Hose Grommet

810 ft (3 m) Water Return Hose

9Connection Block

Route one end of remaining water hose through grommet, and con- nect to rear of connection block (not shown). Connect remaining end of hose to return fitting on coolant supply.

10Weld Cable Grommet

11Weld Cable To Welding Power Source

Select and prepare weld cable according to welding power source manual.

12Current Sensing (Reed) Relay

13Weld Cable Screw In Feeder

Route one end of weld cable through grommet, through reed relay, and connect to block in feeder using hardware shown. Connect remaining end of cable to positive

(+)weld output terminal on welding power source.

Close and latch door.

Tools Needed:

5/8,

Ref. 152