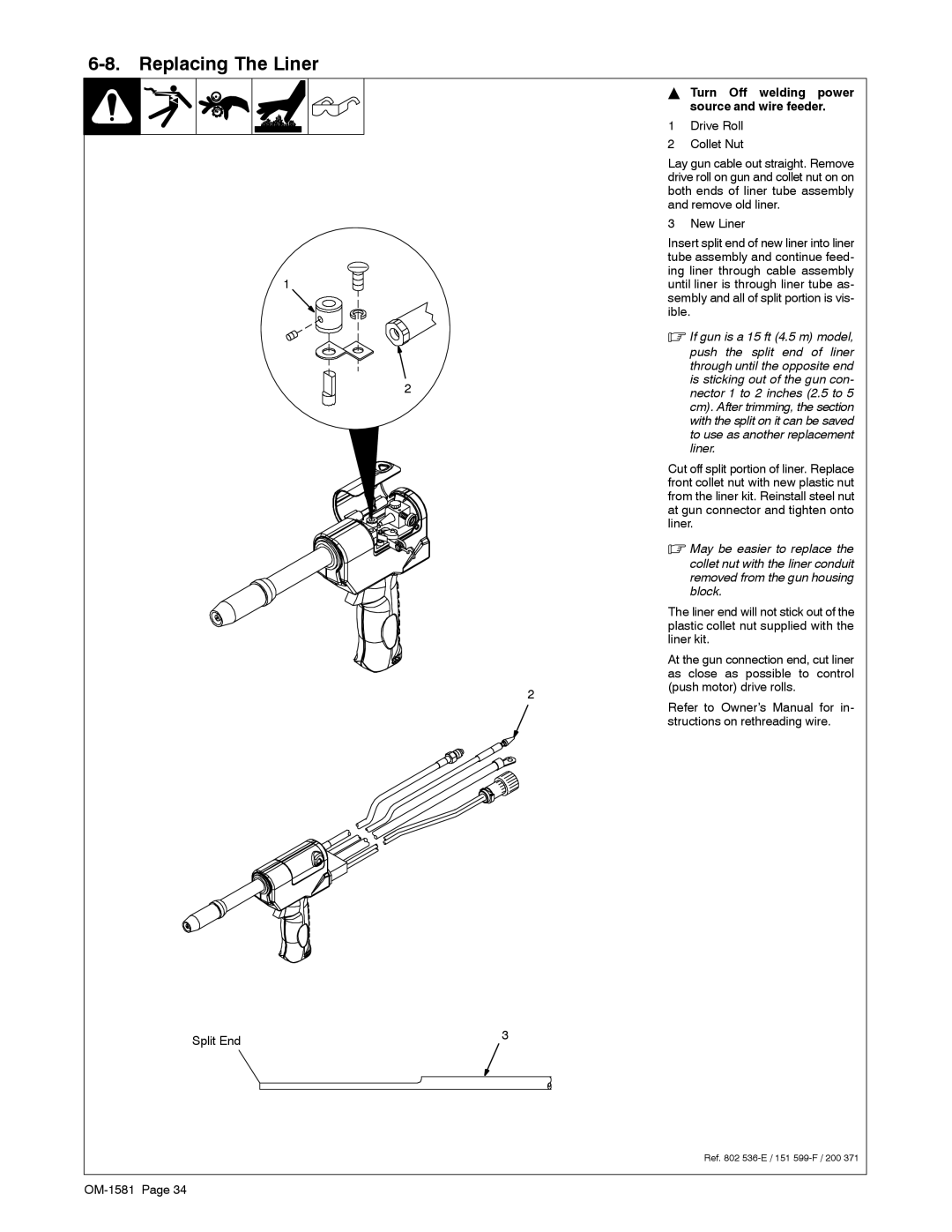

6-8. Replacing The Liner

1

2

2

Split End | 3 |

|

YTurn Off welding power source and wire feeder.

1Drive Roll

2Collet Nut

Lay gun cable out straight. Remove drive roll on gun and collet nut on on both ends of liner tube assembly and remove old liner.

3 New Liner

Insert split end of new liner into liner tube assembly and continue feed- ing liner through cable assembly until liner is through liner tube as- sembly and all of split portion is vis- ible.

.If gun is a 15 ft (4.5 m) model,

push the split end of liner through until the opposite end is sticking out of the gun con- nector 1 to 2 inches (2.5 to 5 cm). After trimming, the section with the split on it can be saved to use as another replacement liner.

Cut off split portion of liner. Replace front collet nut with new plastic nut from the liner kit. Reinstall steel nut at gun connector and tighten onto liner.

.May be easier to replace the collet nut with the liner conduit removed from the gun housing block.

The liner end will not stick out of the plastic collet nut supplied with the liner kit.

At the gun connection end, cut liner as close as possible to control (push motor) drive rolls.

Refer to Owner’s Manual for in- structions on rethreading wire.

Ref. 802