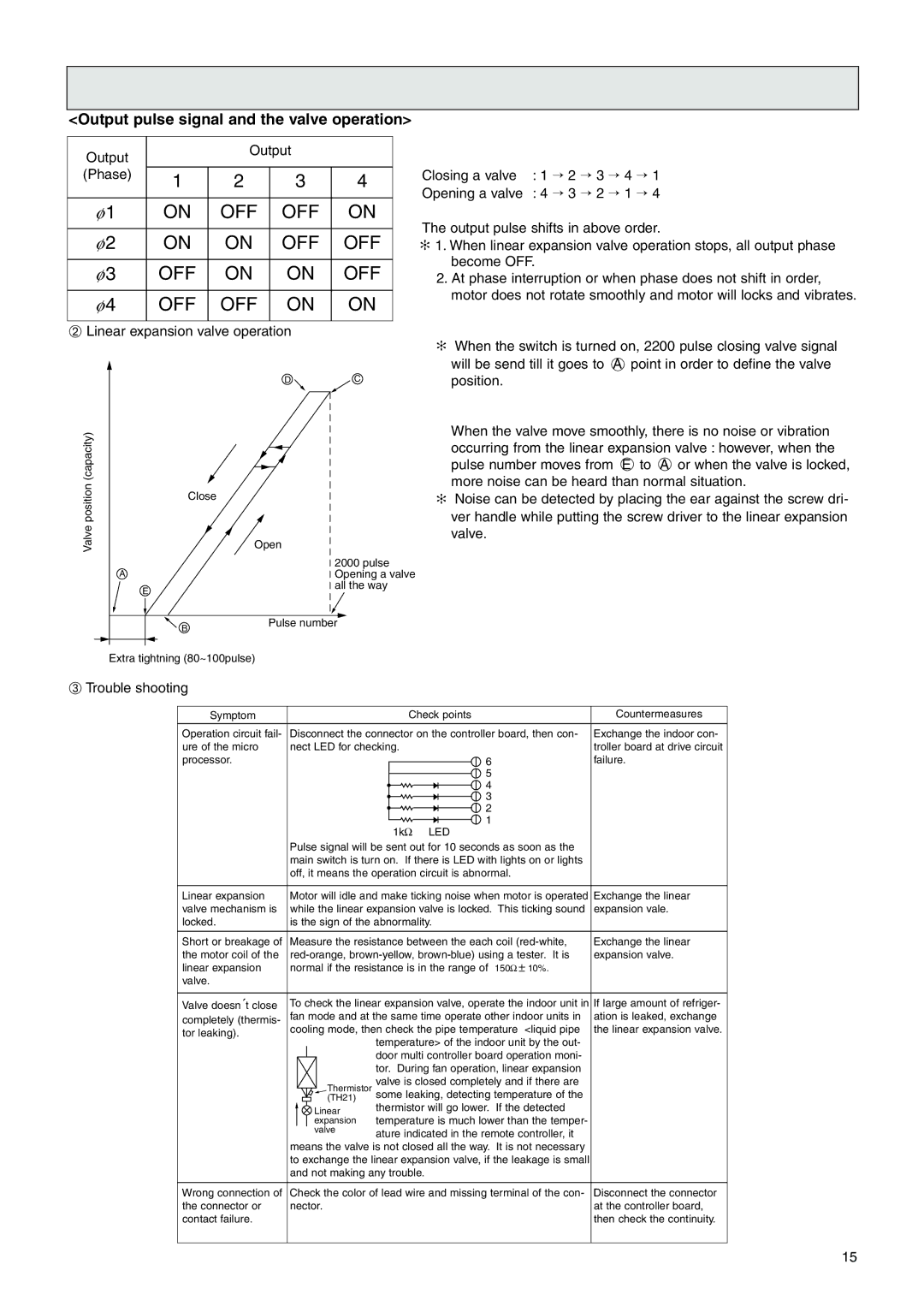

<Output pulse signal and the valve operation>

Output |

| Output |

| |

|

|

|

| |

(Phase) | 1 | 2 | 3 | 4 |

| ||||

|

|

|

|

|

ø1 | ON | OFF | OFF | ON |

|

|

|

|

|

ø2 | ON | ON | OFF | OFF |

|

|

|

|

|

ø3 | OFF | ON | ON | OFF |

|

|

|

|

|

ø4 | OFF | OFF | ON | ON |

|

|

|

|

|

➁Linear expansion valve operation

|

| D | C |

(capacity) |

|

|

|

position |

| Close |

|

|

|

| |

Valve |

| Open |

|

|

|

| 2000 pulse |

| A |

| Opening a valve |

| E |

| all the way |

|

|

| |

| B | Pulse number | |

|

|

| |

Closing a valve | : 1 → 2 → 3 → 4 → 1 |

Opening a valve | : 4 → 3 → 2 → 1 → 4 |

The output pulse shifts in above order.

✻1. When linear expansion valve operation stops, all output phase become OFF.

2.At phase interruption or when phase does not shift in order, motor does not rotate smoothly and motor will locks and vibrates.

✻When the switch is turned on, 2200 pulse closing valve signal will be send till it goes to A point in order to define the valve position.

When the valve move smoothly, there is no noise or vibration occurring from the linear expansion valve : however, when the pulse number moves from E to A or when the valve is locked, more noise can be heard than normal situation.

✻Noise can be detected by placing the ear against the screw dri- ver handle while putting the screw driver to the linear expansion valve.

Extra tightning (80~100pulse)

➂ Trouble shooting

Symptom |

|

|

|

|

|

| Check points |

|

|

|

| Countermeasures |

|

|

|

|

|

|

|

|

|

|

|

| |

Operation circuit fail- | Disconnect the connector on the controller board, then con- | Exchange the indoor con- | ||||||||||

ure of the micro | nect LED for checking. |

|

|

|

| troller board at drive circuit | ||||||

processor. |

|

|

|

|

|

| 6 |

|

|

|

| failure. |

|

|

|

|

|

|

| 5 |

|

|

|

|

|

|

|

|

|

|

|

| 4 |

|

|

|

|

|

|

|

|

|

|

|

| 3 |

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

|

|

|

|

|

| 1kΩ LED |

|

|

|

|

|

| Pulse signal will be sent out for 10 seconds as soon as the |

| ||||||||||

| main switch is turn on. If there is LED with lights on or lights |

| ||||||||||

| off, it means the operation circuit is abnormal. |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |

Linear expansion | Motor will idle and make ticking noise when motor is operated | Exchange the linear | ||||||||||

valve mechanism is | while the linear expansion valve is locked. This ticking sound | expansion vale. | ||||||||||

locked. | is the sign of the abnormality. |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |

Short or breakage of | Measure the resistance between the each coil | Exchange the linear | ||||||||||

the motor coil of the | expansion valve. | |||||||||||

linear expansion | normal if the resistance is in the range of 150Ω |

|

|

| 10%. |

| ||||||

valve. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Valve doesn´t close | To check the linear expansion valve, operate the indoor unit in | If large amount of refriger- | ||||||||||

completely (thermis- | fan mode and at the same time operate other indoor units in | ation is leaked, exchange | ||||||||||

tor leaking). | cooling mode, then check the pipe temperature |

|

| <liquid pipe | the linear expansion valve. | |||||||

|

|

|

|

|

| temperature> of the indoor unit by the out- |

| |||||

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| door multi controller board operation moni- |

| ||||

|

|

|

|

|

|

| tor. During fan operation, linear expansion |

| ||||

|

|

|

|

|

| Thermistor | valve is closed completely and if there are |

| ||||

|

|

|

|

|

| (TH21) | some leaking, detecting temperature of the |

| ||||

|

|

|

|

|

|

| ||||||

|

|

|

|

| Linear | thermistor will go lower. If the detected |

| |||||

|

|

|

|

|

| |||||||

|

|

|

|

| expansion | temperature is much lower than the temper- |

| |||||

|

|

|

|

| valve | ature indicated in the remote controller, it |

| |||||

|

|

|

|

|

|

|

| |||||

| means the valve is not closed all the way. It is not necessary |

| ||||||||||

| to exchange the linear expansion valve, if the leakage is small |

| ||||||||||

| and not making any trouble. |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |

Wrong connection of | Check the color of lead wire and missing terminal of the con- | Disconnect the connector | ||||||||||

the connector or | nector. |

|

|

|

|

| at the controller board, | |||||

contact failure. |

|

|

|

|

|

|

|

|

|

|

| then check the continuity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

15