ASSEMBLY INSTRUCTIONS/OPERATIONS

![]() DANGER

DANGER

DO NOT OPERATE A GASOLINE ENGINE IN

CLOSED SPACES WITHOUT PROPER VENTILATION. GASOLINE ENGINES PRODUCE CARBON MONOXIDE FUMES. BREATHING CARBON MONOXIDE FUMES CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY. EXCESSIVE LEVELS OF CARBON MONOXIDE CAN CAUSE DEATH.

1)Flail cutting depth is controlled by the height adjustment lever . Rotate the lever counterclockwise to raise the flail drum off the work surface. Rotate the lever clockwise to lower the flail drum to the work surface. The height adjustment lever can be locked in position by dropping the connecting capscrew head through one of the two holes provided. FIGURE 27.

FIGURE 27

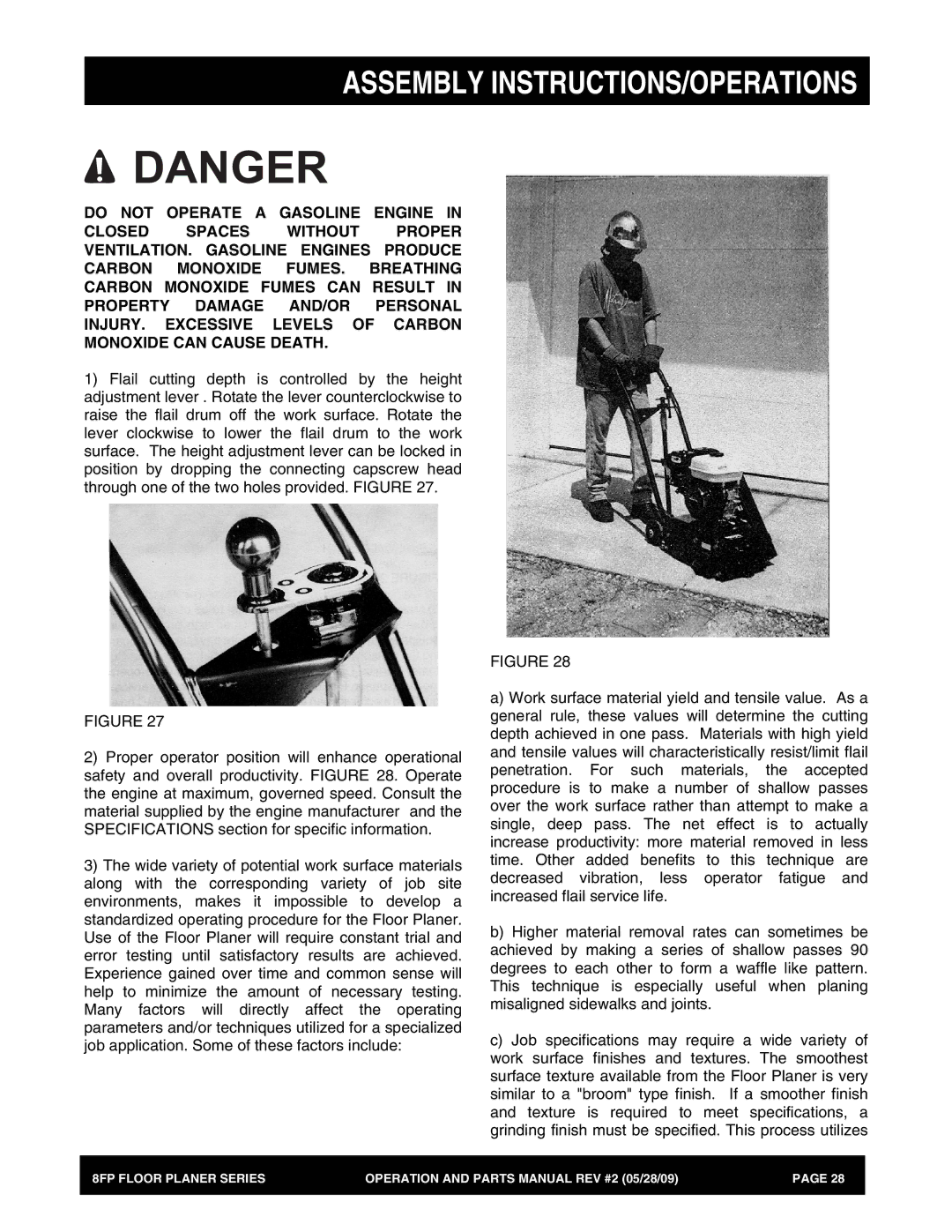

2)Proper operator position will enhance operational safety and overall productivity. FIGURE 28. Operate the engine at maximum, governed speed. Consult the material supplied by the engine manufacturer and the SPECIFICATIONS section for specific information.

3)The wide variety of potential work surface materials along with the corresponding variety of job site environments, makes it impossible to develop a standardized operating procedure for the Floor Planer. Use of the Floor Planer will require constant trial and error testing until satisfactory results are achieved. Experience gained over time and common sense will help to minimize the amount of necessary testing. Many factors will directly affect the operating parameters and/or techniques utilized for a specialized job application. Some of these factors include:

FIGURE 28

a) Work surface material yield and tensile value. As a general rule, these values will determine the cutting depth achieved in one pass. Materials with high yield and tensile values will characteristically resist/limit flail penetration. For such materials, the accepted procedure is to make a number of shallow passes over the work surface rather than attempt to make a single, deep pass. The net effect is to actually increase productivity: more material removed in less time. Other added benefits to this technique are decreased vibration, less operator fatigue and increased flail service life.

b)Higher material removal rates can sometimes be achieved by making a series of shallow passes 90 degrees to each other to form a waffle like pattern. This technique is especially useful when planing misaligned sidewalks and joints.

c)Job specifications may require a wide variety of work surface finishes and textures. The smoothest surface texture available from the Floor Planer is very similar to a "broom" type finish. If a smoother finish and texture is required to meet specifications, a grinding finish must be specified. This process utilizes

8FP FLOOR PLANER SERIES | OPERATION AND PARTS MANUAL REV #2 (05/28/09) | PAGE 28 |

|

|

|