ASSEMBLY INSTRUCTIONS/OPERATIONS

FIGURE 44

10)Mount the bearing block/driveshaft assembly to the main frame. Tighten the 3/8 inch

11)Follow the instructions as outlined for

INSTALLING A

Aproperly installed, replacement bearing should rotate without excessive friction, drag and/or "rough spots". If these symptoms occur after assembly, the bearing was improperly supported when pressed on the driveshaft or into the housing. The resulting thrust placed upon the bearing exceeded its static capacity. A bearing operating with these characteristics will deliver minimal service life and be prone to premature failure.

12)If the Floor Planer is powered by an engine, reconnect the engine spark plug wire. If powered by an electric motor and the machine is to be used immediately, reconnect the extension cord or Surface Grinder to the power source. Determine that the ON/OFF switch located on the operator handle is in the OFF position.

![]() DANGER

DANGER

UNEXPECTED MACHINE START UP CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

INSTALLING A REPLACEMENT BEARING ON THE

OUTBOARD SIDE.

Application: All Models.

Tools Required:

1each, 5/16 wrench.

1each, 3/4 wrench.

1each, 5/16 Allen wrench.

1 each, arbor press.

1each, torque wrench, 85 ft lbs (115 Nm.) capacity, with 5/15 inch, male Allen head and 9/16 socket.

1each, pliers for large, external type snap rings.

Parts Required:

1 each,

1 each,

1)If the Floor Planer is powered by an engine, disconnect the spark plug wire. If powered by an electric motor, disconnect the extension cord or Floor Planer from the power source.

2)Position the Floor Planer on a suitable work surface with the

3)Using a 3/4 inch wrench, remove the access plate capscrews. Remove the access plate.

4)Using the 5/16 inch Allen wrench and 9/16 inch wrench, remove the bearing block from the access plate. For accuracy and alignment purposes, the access plate incorporates tapped holes to properly position the capscrews.

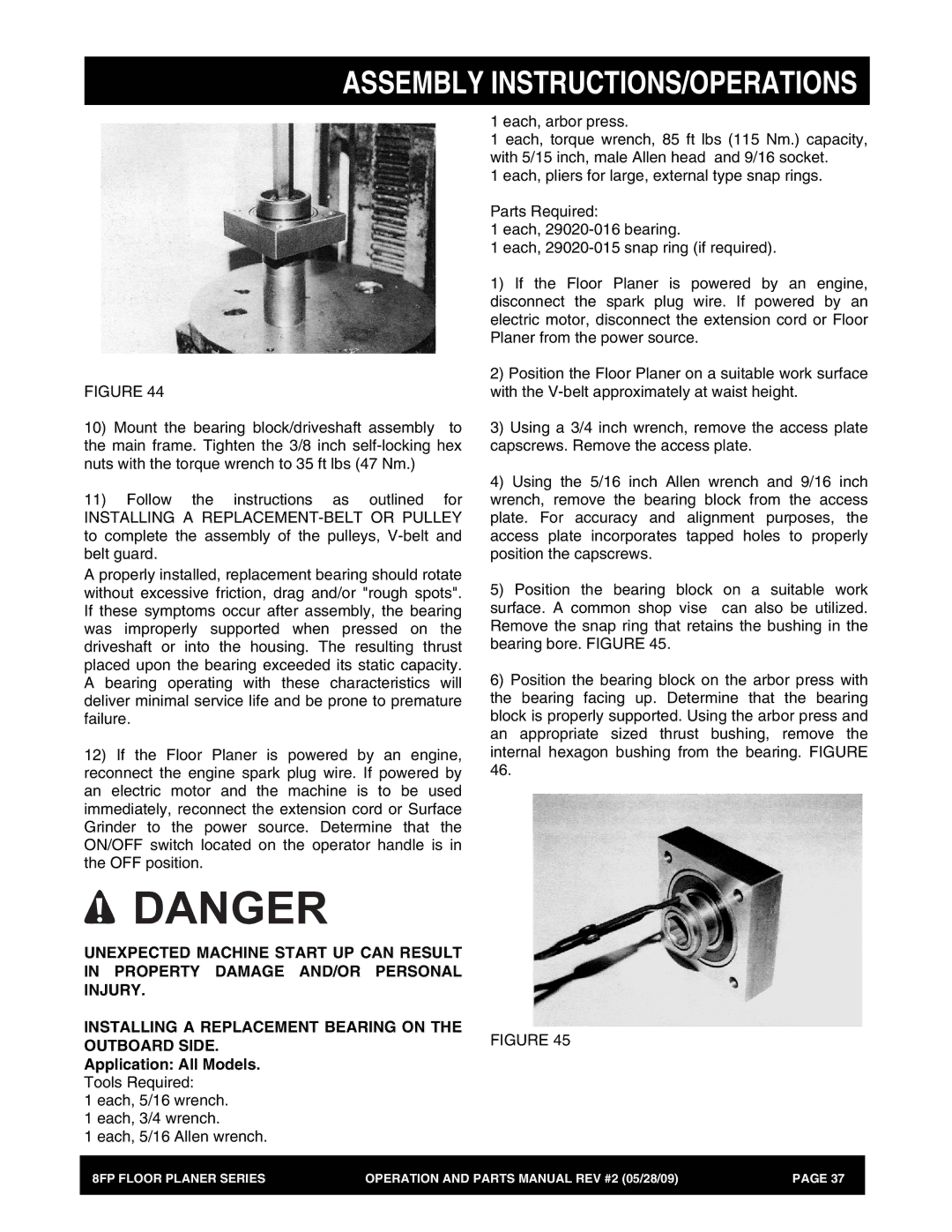

5)Position the bearing block on a suitable work surface. A common shop vise can also be utilized. Remove the snap ring that retains the bushing in the bearing bore. FIGURE 45.

6)Position the bearing block on the arbor press with the bearing facing up. Determine that the bearing block is properly supported. Using the arbor press and an appropriate sized thrust bushing, remove the internal hexagon bushing from the bearing. FIGURE 46.

FIGURE 45

8FP FLOOR PLANER SERIES | OPERATION AND PARTS MANUAL REV #2 (05/28/09) | PAGE 37 |

|

|

|