Models LS400/LS500

Diesel engine exhaust and some

Page

LS400/LS500 Pump -TABLE of Contents

Parts Ordering Procedures

Ordering parts has never been easier

You can be injured if you do not follow directions

LS400/LS500 Pump Safety Message Alert Symbols

Is running or hot

LS400/LS500 Pump Safety Message Alert Symbols

Always wear approved respiratory protection

General Safety

LS400/LS500 Pump Rules for Safe Operation

Towing

LS400/LS500 Pump Rules for Safe Operation

Transporting

Emergencies

Maintenance Safety

Battery

Always know the location of the nearest and first aid kit

Page

LS400/LS500 Pump Specifications

Pump Specifications

Dimensions

Dimensions

LS400/LS500 Pump Important Hand Signals

Operation Hand Signals

LS400/LS500 Pump General Information

Concrete MIX Design

LS400/LS500 Pump General Information

Regional Differences

LS400/LS500 Pump HOW IT Works

Pumping Cycle

LS400/LS500 Pump Pump Components

LS400/LS500 Pump Pump Components

Operation

Switch controls the pumping function. The leftmost

LS400/LS500 Pump Digital Control Panel Components

Counterclockwise to the Stop position

LS400/LS500 Pump Digital Readout Screen

Primary Screen

LS400/LS500 Pump Engine Components

Initial Servicing

Check fastening nuts and bolts for tightness

Fuel Check

Before Starting

Remove the engine oil dipstick from its holder Figure

LS400/LS500 Pump Inspection

Engine OIL Check

Hydraulic OIL Check

Hydraulic Oil Filler Hole

Rear Stabilizer Jacks

LS400/LS500 Pump SET-UP

Location of Pump

Hydraulic Rear Stabilizer Jacks Optional

LS400/LS500 Pump START-UP Procedure

Starting Procedure

Pumping

LS400/LS500 Pump Operation

Hose Lubrication

Priming the Pump with Slurry Mixture

Accumulator Pressure Gauge

Remote Control Optional

Radio Remote Control

Cable Remote Control

LS400/LS500 Pump Operation

Vertical Pumping

Remixtures

Downhill Pumping

Hose Pulsation

NEW Pumps

LS400/LS500 Pump Pumping Information

SNAP-JOINT Couplings

Effects of Heat and Excessive Time on Concrete

Clearing the System After MIX SET UP

Clearing Concrete Blockage

Clearing Shuttletube Blockage

Reverse Pumping Procedure

Shuttle Tube Inspection Procedure

LS400/LS500 Pump Maintenance Pump

Cleaning the Pump and Delivery System

LS400/LS500 Pump Maintenance Pump

Hydraulic OIL System Maintenance

Battery Maintenance

Brake System

Accumulator Circuit

Cleaningthe Lubrication BOX

Cylinder Lubrication BOX

LS400/LS500 Pump Maintenance Pump

Size and type of aggregate Type of concrete being pumped

Off

Wear Ring installation

Wear Plate and Ring Replacement Procedure

Wear Plate Installation

Changingthe Wear Plate and Ring

Pressure Test

Wheel Bearings

Extended Storage Instructions

Hydraulic Brakes

Manually Adjusting the Brakes

Trailer Brakes

LS400/LS500 Pump Maintenance Trailer

Adjustable Channel

Torsion Suspension

Tube

Common Causes for Loss of Trailer

LS400/LS500 Pump -TRAILER Safety Guidelines

Always use lower gears for climbing and descending grades

Trailer Towing Guidelines

Driving Conditions

Coupling to the Tow Vehicle

Trailer Towing Tips

Reporting Safety Defects

Inoperable Brakes, Lights or Mirrors

LS400/LS500 Pump Trailer Safety Guidelines

Trailer VIN Tag

Trailer Lighting and Braking Connector

Electrical Connector

Safety Chains

Tow Vehicle

Coupler Types

Ball Hitch Coupler

Ball Hitch Coupling Mechanism

Breakaway Brake System

Attaching Safety Chain

Attach the safety chains so that they

Uncoupling the Ball Hitch

LS400/LS500 Pump Trailer Safety Guidelines

Connecting Trailer Lights

Unsafe Tires, Lug Nuts or Wheels

Determining Load Limit of Trailer

Tire and Loading Information Placard

Tire Fundamentals

Step

Determining Load Limit of Tow Vehicle Step

Uniform Tire Quality Grading Standards Utqgs

P indicates the tire is for passenger vehicles

Replacing Worn or Damaged Tires

Tire Safety Tips

Tire Repair

Load Range

Lug Nut Torque Requirements

Wheel Rims

Wheels, Bearings and Lug Nuts

Start all wheel lug nuts by hand

Trailer to Tow Vehicle Wiring Diagram

Lights and Signals

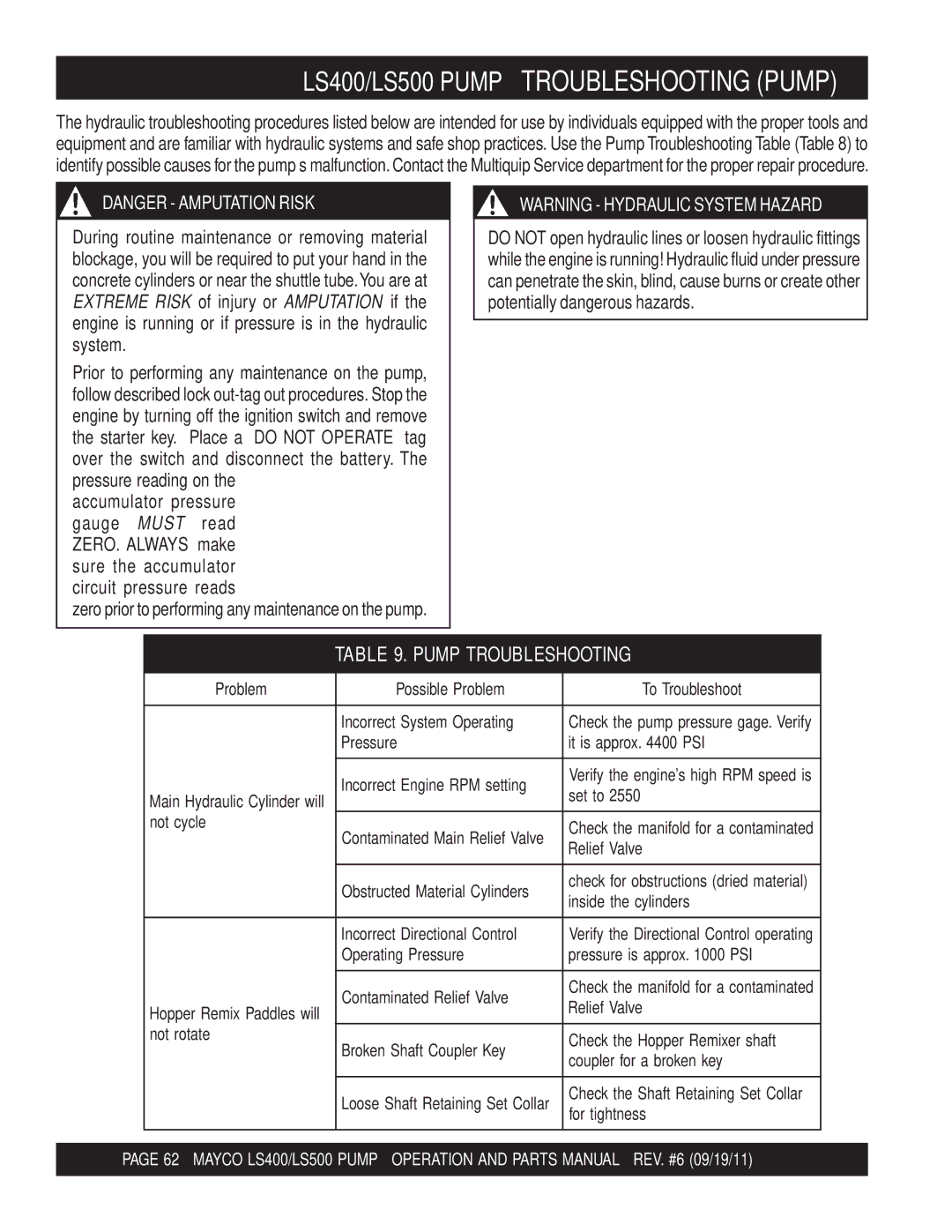

LS400/LS500 Pump Troubleshooting Pump

Zero prior to performing any maintenance on the pump

LS400/LS500 Pump Troubleshooting Pump

PSI

LS400/LS500 Pump -TROUBLESHOOTING Engine

Engine Troubleshooting

LS400/LS500 Pump -TROUBLESHOOTING Trailer Brake System

Brake System Troubleshooting

Refer to for the location of components for troubleshooting

LS400/LS500 Pump Troubleshooting Electrical

Electrical Troubleshooting

Malfunction

LS400/LS500 Pump Troubleshooting Electrical

Probable Cause Solution

Location of Components for Electrical Troubleshooting

LS400/LS500 Pump Wiring Diagram Control BOX

Connections to Digital Control Box J1 and J2 Connectors 1

LS400/LS500 Pump Wiring Diagram Control BOX

Connections to Digital Control Box J1 and J2 Connectors 2

Connections to Digital Control Box J3 and J4 Connectors 1

Connections to Digital Control Box J3 and J4 Connectors 2

LS400/LS500 Pump Wiring Diagram Hopper Vibrator

Optional Hopper Vibrator Wiring Diagram

LS400/LS500 Pump Hydraulic System Diagram

Hydraulic System Diagram

LS400/LS500 Pump Manifold Block Ports

Manifold Block Ports

Appendix Concrete MIX Information

Appendix Concrete MIX Information

Appendix Slumptest Procedure

Appendix Recommended Shotcrete System

Recommended Shotcrete System

Recommended Shotcrete System NO. Part no Part Name

13 EM23808D Nozzle ASSEMBLY, 2 H-D

Appendix Recommended Shotcrete System

10 EM23101 AIR Vibrator Assy

Has Passed Through the Entire Hose Length

Appendix Recommended Shotcrete Accessories

Recommended Shotcrete Accessories

Part Name QTY Remarks

LS400/LS500 Pump Explanation of Code in Remarks Column

Xxxxx only Not Used on

LS400/LS500 Pump Suggested Spare Parts

Unit

LS400/LS500 Pump Nameplate and Decals

Nameplate and Decals

DECAL, Hopper REX Mixer TBD

DECAL, Engine RPM Setting

DECAL, Maintenance

DECAL, Minimum OIL Level

LS400/LS500 Pump Nameplate and Decals

Included W/ITEM

TBD DECAL, Fault Locator

TBD DECAL, Impact Hazard

DECAL, Hydraulic OIL only

LS400/LS500 Pump Frame Assy

Frame Assy

Clevis PIN

FRAME, Main

Jack STAND, Front

PIN

LS400/LS500 Pump Axle ASSY. RIGHT/LEFT

Axle ASSY. RIGHT/LEFT

Inner Bearing Cone 2

LS400/LS500 Pump Brake Line Assy

Brake Line Assy

KIT, Main Brake Line

LS400/LS500 Pump Brake Light Assy

Brake Light Assy

29242

29207

LS400/LS500 Pump -TRAILER Hitch Assy

Trailer Hitch Assy

ACTUATOR, Brake

LS400/LS500 Pump Battery Assy

LS400/LS500 Pump Battery Assy

LS400/LS500 Pump Hopper Assy

Hopper Assy

Remixer Shaft

Housing

Hopper Seal

Follower Ring

LS400/LS500 Pump Hopper Attachment Assy

Hopper Attachment Assy

PIN, Splash Plate

Splash Plate

Hinge PIN

TIE ROD

LS400/LS500 Pump Hopper Interior Assy

Hopper Interior Assy

Wear Ring HF

Swing Axle Bushing

Ring SEAL, Shuttle Axle

RING, Energizer Rubber

LS400/LS500 Pump Shuttle Cylinder Assy

Shuttle Cylinder Assy

HEX NUT 1 in NF

Thrust Washer

Tensioner

Cotter PIN 5/32 X 2

LS400/LS500 Pump Lubrication Pistons Assy

Lubrication Pistons Assy

Cable HOUSING, Female

BAR,PROXIMITY Switch Support

SWITCH, Proximity W/CABLE

SEAL, Connector Housing

LS400/LS500 Pump Lubrication Pistons Assy

BOLT, HEX Head 5/16 NC X 1 IN. G5

Adjustment ROD, Proximity Switch

BRACKET, Adjustment ROD

WASHER, Lock 5/16

LS400/LS500 Pump Fueltank Assy

Fuel Tank Assy

CAP, Fuel W\GAUGE

COVER, Diesel Tank

Gasket

Adaptor

LS400/LS500 Pump Heat Exchanger Assy

Heat Exchanger Assy

Hose 4000 PSI

Heat Exchanger

COVER, Heat Exchanger

Hose 2000 PSI

LS400/LS500 Pump Accumulator Assy

Accumulator Assy

Part Name QTY

LS400/LS500 Pump Remixer Control Assy

Remixer Control Assy

Adapter FITTING, 90 Elbow

Valve Remixer W/ Lever

Adapter FITTING, T

Adapter FITTING, Straight

Position Location

LS400/LS500 Pump Lubrication Panel

Grease Points

HOSE, Plastic

Connector

Lubrication Panel Assy

HOSE, Steel

LS400/LS500 Pump Engine Cover Assy

Engine Cover Assy

Document Cylinder

COVER, TOP

COVER, Front Engine

LS400/LS500 Pump Hydraulictank Assy

Hydraulic Tank Assy

Hydraulic TANK, LS-S

LS400/LS500 Pump Engine Assy

LS-40TD/LS-50TD Engine Assy

CARTRIDGE, Safety AIR

CONNECTOR, AIR Filter

HOOD, AIR Cleaner

Engine Assy

LS400/LS500 Pump -THROTTLE Assy

Throttle Assy

Support

EM98233

LS400/LS500 Pump -WATER Separator Assy

Water Separator Assy

BRACKET, Water Separator TBD Bolt

LS400/LS500 Pump HYD. Pump Assy

Hydraulic Pump Assy

EM492444 Bolt 1/2 X 1-1/4

ADAPTER, Suction Pipe

LS400/LS500 Pump Manifold Assy

Manifold Assy Front Machine

Pilot VALVE, Main Cylinder

EMBK227

Pilot VALVE, Shuttle

Check Valve

LS400/LS500 Pump Control BOX Assy

Control BOX Assy

Contact BLOCKS, Emergency Switch

Ignition Switch Assy

Emergency Stop Switch Assy

Flow Direction Switch Assy

LS400/LS500 Pump Control BOX Harnesses Assy

Control BOX Harnesses Assy

Conductive Divider 3/8

Wire Harness

FUSE, 30 AMP

LS400/LS500 Pump Remote Control Cable Assy

Remote Control Cable Assy

Guard Switch Aluminum

Switch

CONNECTOR, Ring 3/16

Junction BOX

LS400/LS500 Pump Hydraulic Stabilizer ASSY. Optional

LS400/LS500 Pump Hydraulic Stabilizer ASSY. Optional

Terms and Conditions of Sale Parts

Freight Policy

Mayco Pumpwarranty

Mechanical Drive Models

HERE’S HOW to GET Help