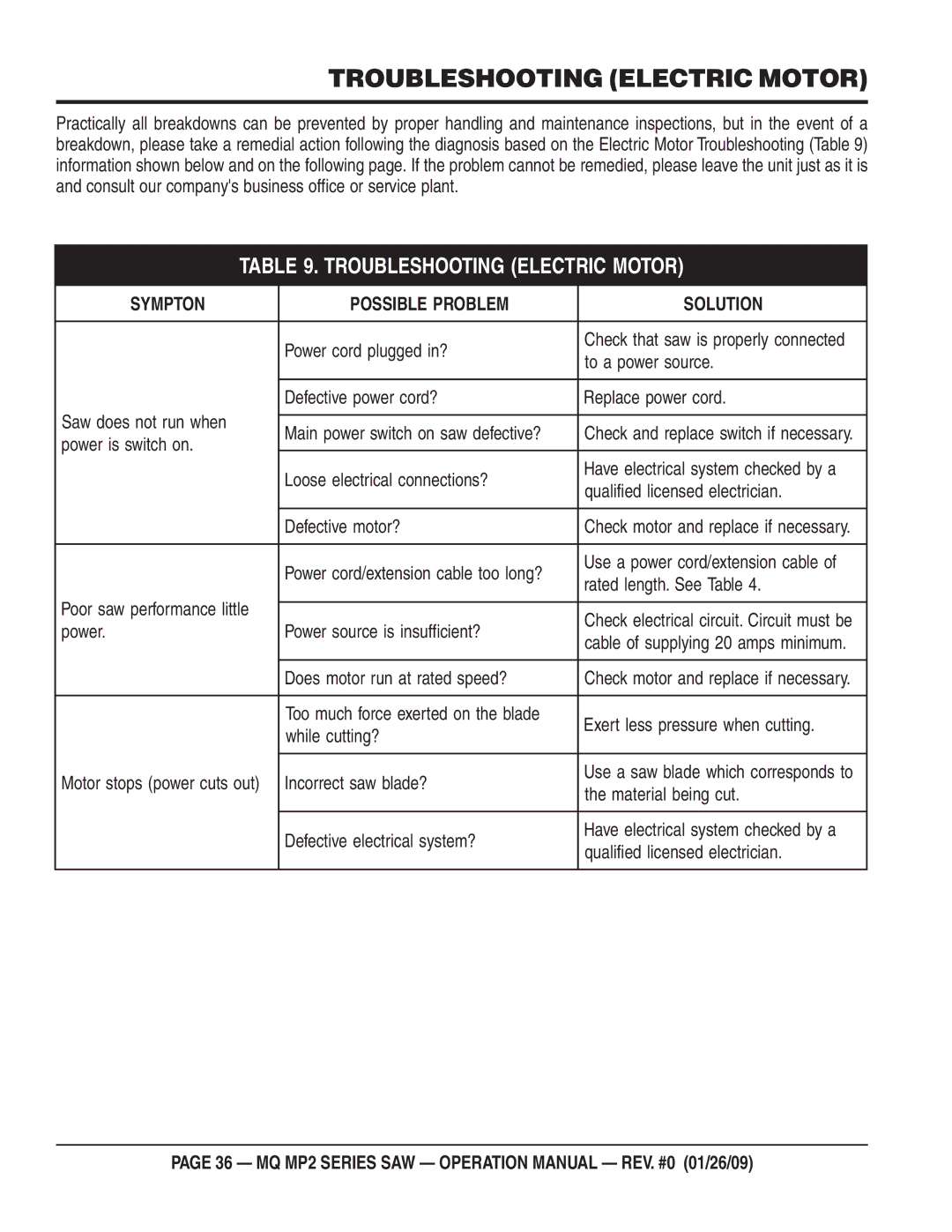

TROUBLESHOOTING (ELECTRIC MOTOR)

Practically all breakdowns can be prevented by proper handling and maintenance inspections, but in the event of a breakdown, please take a remedial action following the diagnosis based on the Electric Motor Troubleshooting (Table 9) information shown below and on the following page. If the problem cannot be remedied, please leave the unit just as it is and consult our company's business office or service plant.

TABLE 9. TROUBLESHOOTING (ELECTRIC MOTOR)

SYMPTON | POSSIBLE PROBLEM | SOLUTION | |

|

|

| |

| Power cord plugged in? | Check that saw is properly connected | |

| to a power source. | ||

|

| ||

|

|

| |

| Defective power cord? | Replace power cord. | |

Saw does not run when |

|

| |

Main power switch on saw defective? | Check and replace switch if necessary. | ||

power is switch on. | |||

|

| ||

| Loose electrical connections? | Have electrical system checked by a | |

| qualified licensed electrician. | ||

|

| ||

|

|

| |

| Defective motor? | Check motor and replace if necessary. | |

|

|

| |

| Power cord/extension cable too long? | Use a power cord/extension cable of | |

| rated length. See Table 4. | ||

|

| ||

Poor saw performance little |

|

| |

| Check electrical circuit. Circuit must be | ||

power. | Power source is insufficient? | ||

cable of supplying 20 amps minimum. | |||

|

| ||

|

|

| |

| Does motor run at rated speed? | Check motor and replace if necessary. | |

|

|

| |

| Too much force exerted on the blade | Exert less pressure when cutting. | |

| while cutting? | ||

|

| ||

|

|

| |

Motor stops (power cuts out) | Incorrect saw blade? | Use a saw blade which corresponds to | |

the material being cut. | |||

|

| ||

|

|

| |

| Defective electrical system? | Have electrical system checked by a | |

| qualified licensed electrician. | ||

|

| ||

|

|

|

PAGE 36 — MQ MP2 SERIES SAW — OPERATION MANUAL — REV. #0 (01/26/09)