Model R2000H

Proposition 65WARNING

Page

Table of Contents

Parts Ordering Procedures

Best Deal! Order via Internet Dealers Only

Order via Fax Dealers Only

25 x 7 x 7 in .5 x17.8 x17.8 cm

LH 9 in mm

RH 3.25 in mm LH 1.75 in mm

Drive to rear roll

R2000H Specifications Engine

R2000H Roller Dimensions

R2000H Dimensions

Seriously injured if you do not follow directions

Injury to yourself and others

Instructions

Always wear approved respiratory protection

Rules for Safe Operation

Always wear seat belts

Rules for Safe Operation

Emergencies

Never stand below roller when it is being lifted

Machine Safety Decals

Operation and Safety Decals

Recommended Slope

Do not operate this roller on slippery or wet surfaces

Tipping Rollover

Tipping Rollovers

Page

Roller Components

R2000H Roller Components

Free Wheel Engagement Pin

Tie-Down Transport Points

Attach a chain or suitable tie-down

R2000H Engine Components

Capacity is 400 cc Reference manufacturer engine

R2000H Inspection

Before Starting

Engine Oil Check

Water System Check

Sit down in the operators seat

Place the Choke Lever in the Closed position

Starting the Engine

R2000H Operation

Ignition Switch

Water Sprinklers Control

Place the transmission lever in the neutral position

Emergency Shut-Down

R2000H Maintenance

Lubrication

Hydrostatic Transmission

Drive Chains

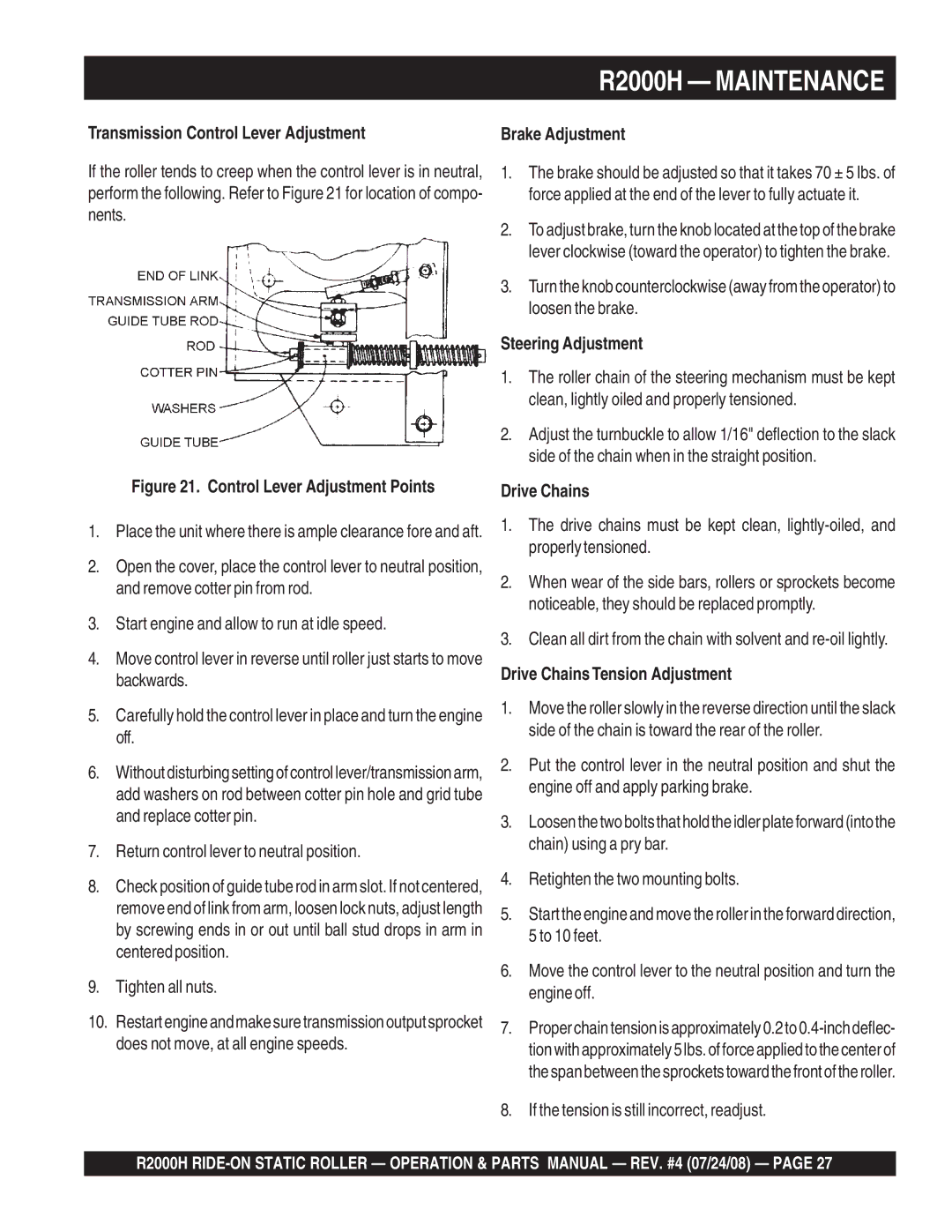

Transmission Control Lever Adjustment

Steering Adjustment

Drive Chains Tension Adjustment

TransmissionV-Belt Adjustment

Use a belt tension tester to check the belt tension

Scrapers, Cocoa Mats, and Sprinkler Bars

Roller Storage

R2000H Preparation for Long -TERM Storage

R2000H Troubleshooting Roller

Engine Troubleshooting

R2000H Troubleshooting Engine

Remarks Column

NO. Column

Part NO. Column

QTY. Column

R2000H Suggested Spare Parts

Name Plate and Decals

R2000H Name Plate and Decals

DECAL, MQ Multiquip

DECAL, MQ R2000H Left

DECAL, MQ R2000H Right

DECAL, MQ

Brake Assy

R2000H Brake Assy

Spacer

Adjustable Yoke

LEVER, Parking Brake

CAP Screw 5/16

Steering Assy

R2000H Steering Assy

Washer 5/8

CAP

Hexnut 5/8

Flatwasher 5/8

Chassis & Covers Assy

R2000H Chassis and Covers Assy

PLATE, Shifter

Main Body Frame

GUARD, Rear

PANEL, Left Side

Battery Assy

R2000H Battery Assy

RED

Battery

CLAMP, Battery

CAP Screw 3/8

Rear Drum Assy

R2000H Rear Drum Assy

Bearing

Sprocket 70 Tooth

SCREW, HEX 5/8

Drive System Assy

R2000H Drive System Assy

PULLEY, Engine 6 MM

Honda GX240K1QAE2

WASHER, Flat 3/8

Clip

Transmission Assy

R2000H Transmission Assy

LEVER, Free Flow Relief

Adjustment ROD

ROD, Adjustment

PUMP, Hydrostatic

Water System Assy

R2000H Water System Assy

CAP, Plastic Water Tank

TANK, Water

Washer 5/16 Flat W

Washer 5/16 Lock

AIR Cleaner Assy

Honda GX240K1QAE2 Engine AIR Cleaner Assy

Collar B, AIR Cleaner

COVER, AIR Cleaner

GROMMET, AIR Cleaner

COLLAR, AIR Cleaner

Camshaft Assy

Honda GX240K1QAE2 Engine Camshaft Assy

Lifter Valve

SPRING, Weight Return

ROD Push

ARM Valve Rocker

Carburetor Assy

Honda GX240K1QAE2 Engine Carburetor Assy

Float SET

PLATE, Lever Setting

Gasket SET

Valve SET, Float

Control Assy

Honda GX240K1QAE2 Engine Control Assy

SPRING, Throttle Return

ARM, Governor

ROD, Governor

SPRING, Governor

Crankcase Cover Assy

Honda GX240K1QAE2 Engine Crankcase Cover Assy

GASKET, Case Cover

WEIGHT, Governor

HOLDER, Governor Weight

PIN, Governor Weight

Crankshaft Assy

Honda GX240K1QAE2 Engine Crankshaft Assy

90745ZE2600 KEY 6.3 X 6.3 X 961006206000

WEIGHT, Balancer

Cylinder Barrel Assy

Honda GX240K1QAE2 Engine Cylinder Barrel Assy

OIL Seal

Switch ASSY., OIL Level

SHAFT, Governor ARM

BOLT, Drain Plug

Cylinder Head Assy

Honda GX240K1QAE2 Engine Cylinder Head Assy

GASKET, Cylinder Head

GUIDE, VALVE, OS, Optional

GUIDE, EX. VALVE, OS, Optional

CLIP, Valve Guide

FAN Cover Assy

Honda GX240K1QAE2 Engine FAN Cover Assy

GROMMET, Drain Hole

CLIP, Wire Harness

CLIP, Tube

Shroud

Flywheel Assy

Honda GX240K1QAE2 Engine Flywheel Assy

KEY, Special Woodruff

FAN, Cooling

Flywheel Comp

NUT, Special 16MM

Fuel Tank Assy

Honda GX240K1QAE2 Engine Fueltank Assy

FILTER, Fuel

Rubber Supporter 107MM

JOINT, Fuel Tank

GASKET, Fuel Filler CAP

Ignition Coil Assy

Honda GX240K1QAE2 Engine Ignition Coil Assy

HOLDER, Stop Switch Wire

CLAMP, Wire

GROMMET, Wire

WIRE, Stop Switch 370MM

Starter Motor Assy

Honda GX390K1QAE2 Starter Motor Assy

Clutch Overrunning

WIRE, Water Cover

Contactor Assy

Armature

Honda GX240K1QAE2 Control BOX Assy

FUSE, Blade 15A Alert UNIT, OIL

Control BOX Assy

CLIP, Purse Lock

TUBE, Fastener

Muffler Assy

Honda GX240K1QAE2 Engine Muffler Assy

PIPE, EX

Muffler

Protector COMP., Muffler

PROTECTOR, EX. Pipe

Piston Assy

Honda GX240K1QAE2 Engine Piston Assy

PISTON, Standard

BOLT, Connecting ROD

Ring SET, PISTON, STD

Ring SET, PISTON, 0.75, Optional

Recoil Starter Assy

Honda GX240K1QAE2 Engine Recoil Starter Assy

SPRING, Starter Return

PULLEY, Recoil Starter

RATCHET, Starter

SPRING, Friction

Engine Labels

Honda GX240K1QAE2 Engine Engine Labels

MARK, OIL ALERT, E

EMBLEM, Internal

LABEL, Caution

MARK, CHOKE, External

Terms and Conditions of Sale Parts

Page

Your Local Dealer is

HERE’S HOW to GET Help