INSPECTION/setup

inspection/setup

1.Read and fully understand this manual, the safety intructions in particular, and the engine manufacturer's manual supplied with the saw.

2.Select the correct blade for each application. Refer to the Blades and Blade Placement sections on pages 20 through 22 for further information.

3.Check blade for wear or damage. Handle all blades with care and ALWAYS replace a damaged blade. Clean the saw, removing dirt and dust, particularly the engine cooling air inlet, carburetor and air cleaner.

4.Check the air filter for dirt and dust. Replace the air filter if it is found to be dirty.

5.Check carburetor for external dirt and dust. Clean with dry compressed air.

6.Check fastening nuts and bolts for tightness.

7.Ensure a suitable water supply is available, hooked up, and used. (connected via garden hose or with an optional water tank supply system).

Engine Oil Check

1.To check the engine oil level, place the saw on secure level ground with the engine stopped. The frame platform must be level to accurately check the engine oil.

2.Remove the filler dipstick from the engine oil filler hole (Figure 5) and wipe it clean.

Figure 5. Engine Oil Dipstick (Removal)

3.Insert and remove the dipstick without screwing it into the filler neck. Check the oil level shown on the dipstick.

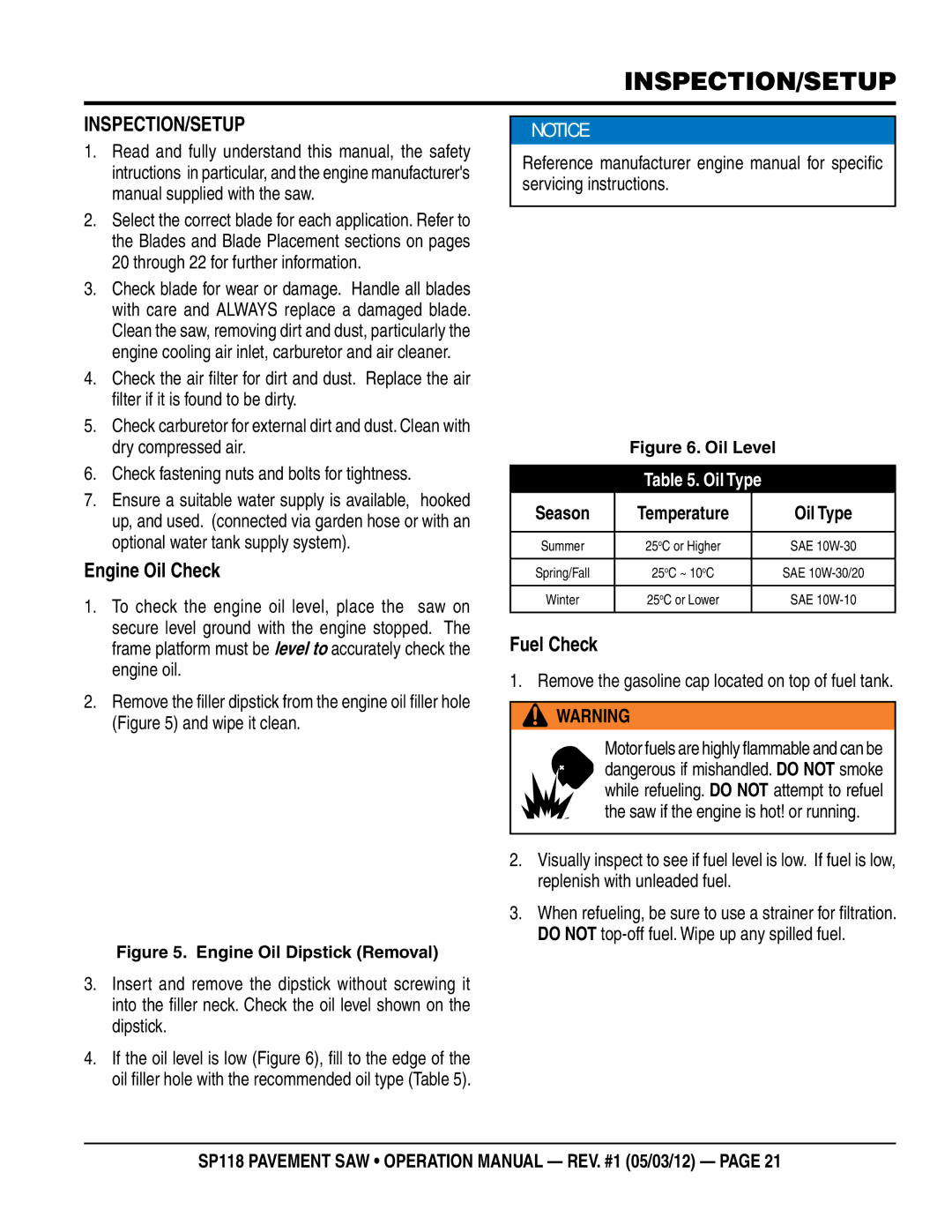

4.If the oil level is low (Figure 6), fill to the edge of the oil filler hole with the recommended oil type (Table 5).

![]() NOTICE

NOTICE

Reference manufacturer engine manual for specific servicing instructions.

UPPER LIMIT

LOWER LIMIT

Figure 6. Oil Level

Table 5. Oil Type

Season | Temperature | Oil Type |

|

|

|

Summer | 25oC or Higher | SAE |

|

|

|

Spring/Fall | 25oC ~ 10oC | SAE |

|

|

|

Winter | 25oC or Lower | SAE |

|

|

|

Fuel Check

1. Remove the gasoline cap located on top of fuel tank.

![]() WARNING

WARNING

Motor fuels are highly flammable and can be dangerous if mishandled. DO NOT smoke while refueling. DO NOT attempt to refuel the saw if the engine is hot! or running.

2.Visually inspect to see if fuel level is low. If fuel is low, replenish with unleaded fuel.

3.When refueling, be sure to use a strainer for filtration. DO NOT

SP118 Pavement Saw • operation manual — rev. #1 (05/03/12) — page 21