TROUBLE SHOOTING GUIDE

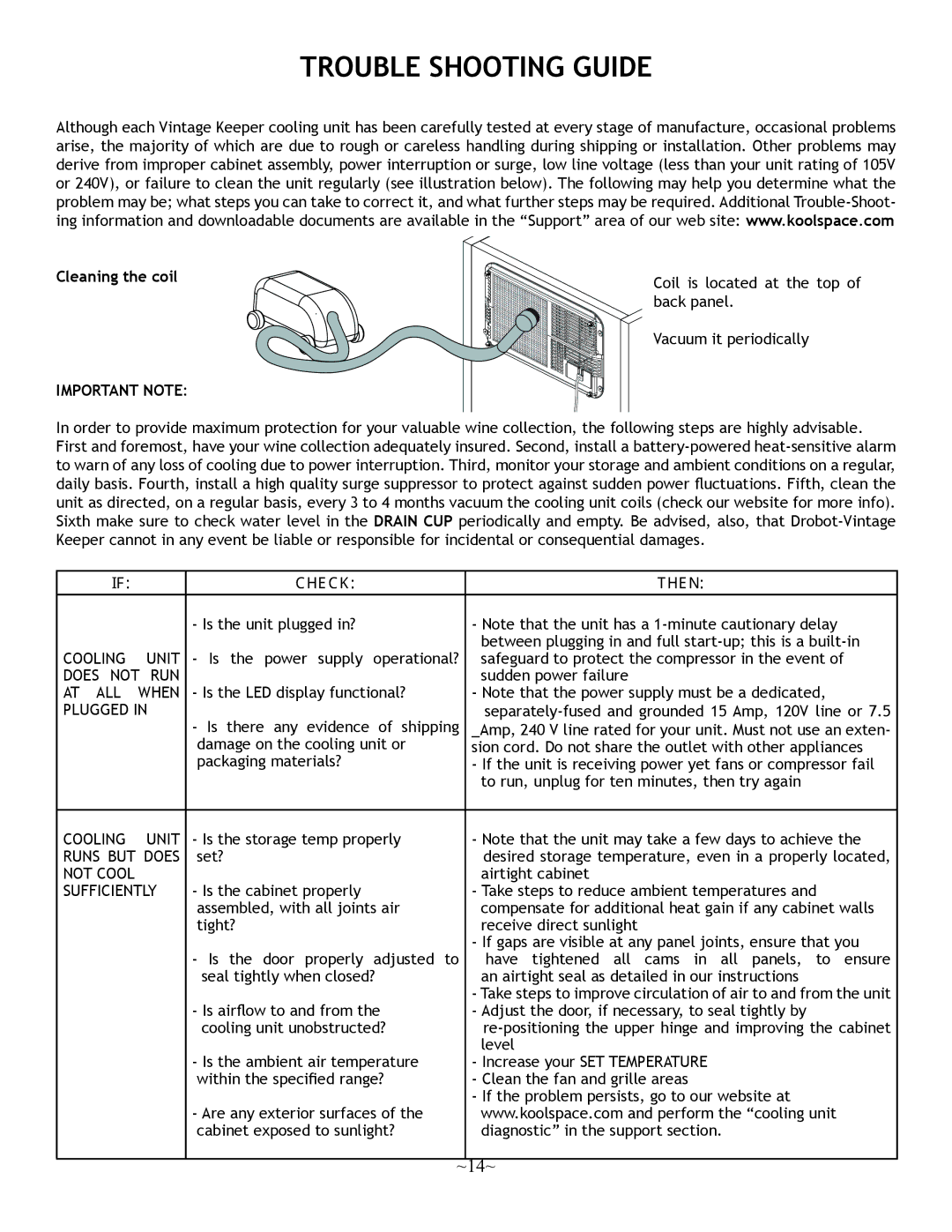

Although each Vintage Keeper cooling unit has been carefully tested at every stage of manufacture, occasional problems arise, the majority of which are due to rough or careless handling during shipping or installation. Other problems may derive from improper cabinet assembly, power interruption or surge, low line voltage (less than your unit rating of 105V or 240V), or failure to clean the unit regularly (see illustration below). The following may help you determine what the problem may be; what steps you can take to correct it, and what further steps may be required. Additional

Cleaning the coil | Coil is located at the top of |

|

back panel.

Vacuum it periodically

IMPORTANT NOTE:

In order to provide maximum protection for your valuable wine collection, the following steps are highly advisable. First and foremost, have your wine collection adequately insured. Second, install a

IF: |

| CHECK: | THEN: |

|

| - Is the unit plugged in? | - Note that the unit has a |

|

|

| between plugging in and full |

COOLING | UNIT | - Is the power supply operational? | safeguard to protect the compressor in the event of |

DOES NOT | RUN |

| sudden power failure |

AT ALL WHEN | - Is the LED display functional? | - Note that the power supply must be a dedicated, | |

PLUGGED IN | - Is there any evidence of shipping | ||

|

| _Amp, 240 V line rated for your unit. Must not use an exten- | |

|

| damage on the cooling unit or | sion cord. Do not share the outlet with other appliances |

|

| packaging materials? | - If the unit is receiving power yet fans or compressor fail |

|

|

| to run, unplug for ten minutes, then try again |

|

|

|

|

COOLING | UNIT | - Is the storage temp properly | - Note that the unit may take a few days to achieve the |

RUNS BUT DOES | set? | desired storage temperature, even in a properly located, | |

NOT COOL |

|

| airtight cabinet |

SUFFICIENTLY | - Is the cabinet properly | - Take steps to reduce ambient temperatures and | |

|

| assembled, with all joints air | compensate for additional heat gain if any cabinet walls |

|

| tight? | receive direct sunlight |

|

|

| - If gaps are visible at any panel joints, ensure that you |

|

| - Is the door properly adjusted to | have tightened all cams in all panels, to ensure |

|

| seal tightly when closed? | an airtight seal as detailed in our instructions |

|

|

| - Take steps to improve circulation of air to and from the unit |

|

| - Is airflow to and from the | - Adjust the door, if necessary, to seal tightly by |

|

| cooling unit unobstructed? | |

|

|

| level |

|

| - Is the ambient air temperature | - Increase your SET TEMPERATURE |

|

| within the specified range? | - Clean the fan and grille areas |

|

|

| - If the problem persists, go to our website at |

|

| - Are any exterior surfaces of the | www.koolspace.com and perform the “cooling unit |

|

| cabinet exposed to sunlight? | diagnostic” in the support section. |

~14~