VI. MAINTENANCE

•Use only a dry, soft cloth for wiping the unit. Do not use a damp cloth, thinner, benzine, or other volatile solvents for cleaning.

•In the event that the inside of the tool or battery pack is exposed to water, drain and allow to dry as soon as possible. Carefully remove any dust or iron filings that collect inside the tool. If you experi- ence any problems operating the tool, consult with a repair shop.

VII. TIGHTENING

TORQUE

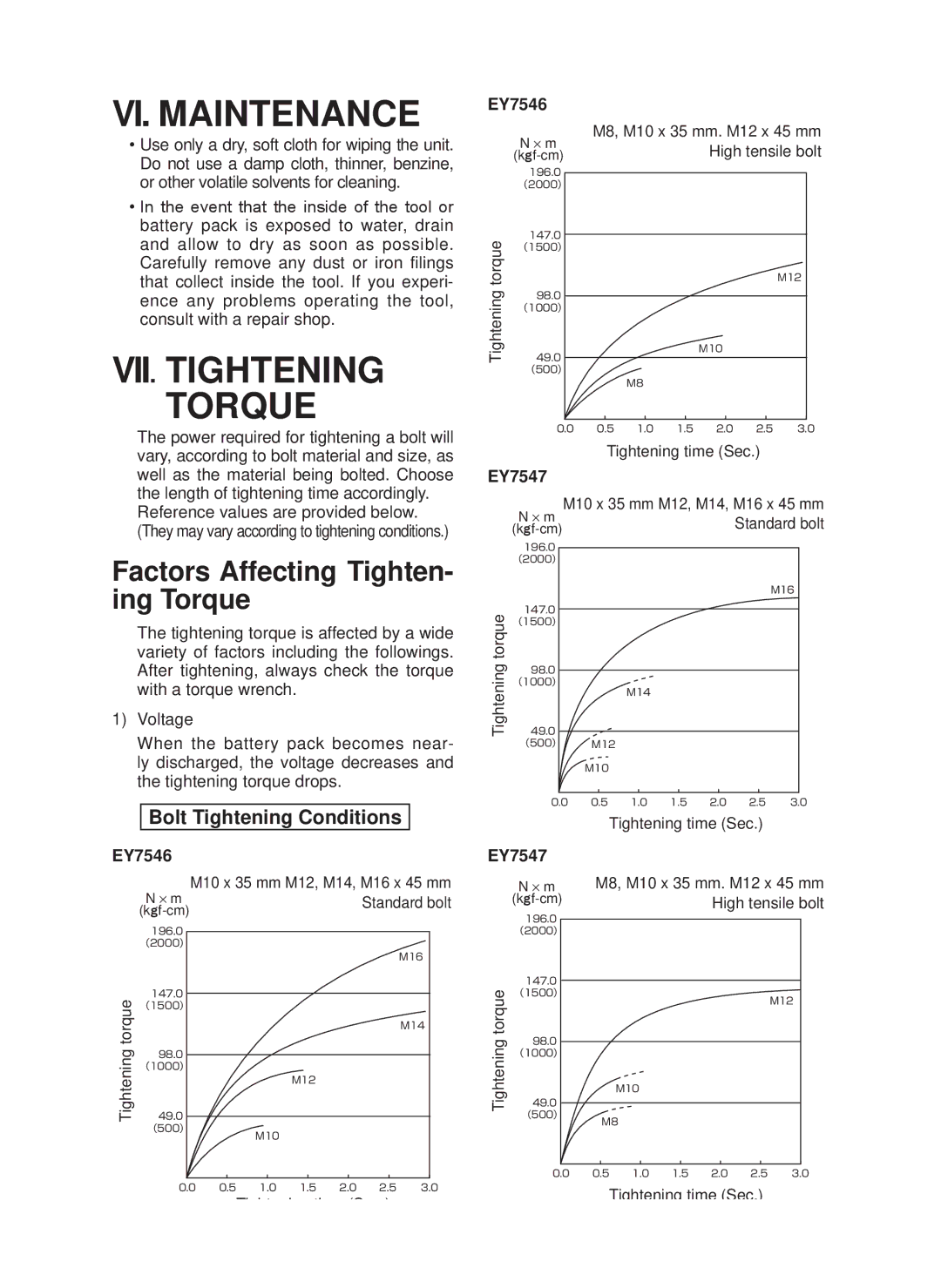

The power required for tightening a bolt will vary, according to bolt material and size, as well as the material being bolted. Choose the length of tightening time accordingly.

Reference values are provided below. (They may vary according to tightening conditions.)

Factors Affecting Tighten ing Torque

The tightening torque is affected by a wide variety of factors including the followings. After tightening, always check the torque with a torque wrench.

1)Voltage

When the battery pack becomes near- ly discharged, the voltage decreases and the tightening torque drops.

Bolt Tightening Conditions

EY7546

M10 x 35 mm M12, M14, M16 x 45 mm

N σ mStandard bolt

| 196.0 |

|

|

|

|

|

|

|

|

| (2000) |

|

|

|

|

|

| M16 |

|

|

|

|

|

|

|

|

|

| |

torque | 147.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

(1500) |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| M14 |

| |

|

|

|

|

|

|

|

|

| |

Tightening | 98.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

49.0 |

|

|

|

|

|

|

|

| |

| (1000) |

|

|

| M12 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| (500) |

|

| M10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | ||

Tightening time (Sec.)

EY7546

M8, M10 x 35 mm. M12 x 45 mm

N σ mHigh tensile bolt

196.0 (2000)

torque | 147.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

(1500) |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| M12 | ||

|

|

|

|

|

|

|

| ||

Tightening | 98.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

49.0 |

|

|

|

|

|

|

|

| |

| (1000) |

|

|

|

|

|

|

| |

|

|

|

|

|

| M10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| (500) |

| M8 |

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | ||

Tightening time (Sec.)

EY7547

M10 x 35 mm M12, M14, M16 x 45 mm

N σ mStandard bolt

196.0 (2000)

|

|

|

|

|

|

|

|

| M16 | |

torque | 147.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

(1500) |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

Tightening | 98.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

49.0 |

|

|

|

|

|

|

|

|

| |

| (1000) |

| M14 |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| (500) | M12 |

|

|

|

|

|

| ||

|

|

|

| M10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | |||

|

|

|

| Tightening time (Sec.) |

|

| ||||

EY7547 |

|

|

|

|

|

|

| |||

| N σ m | M8, M10 x 35 mm. M12 x 45 mm | ||||||||

|

|

|

| High tensile bolt | ||||||

| 196.0 |

|

|

|

|

|

|

|

|

|

| (2000) |

|

|

|

|

|

|

|

| |

torque | 147.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

(1500) |

|

|

|

|

|

| M12 |

| ||

|

|

|

|

|

|

|

|

| ||

Tightening | 98.0 |

|

|

|

|

|

|

|

|

|

(1000) |

|

|

|

|

|

|

|

| ||

|

|

|

|

| M10 |

|

|

|

|

|

| 49.0 |

|

|

|

|

|

|

|

|

|

| (500) |

| M8 |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

| 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | |||

|

|

|

| Tightening time (Sec.) |

|

| ||||