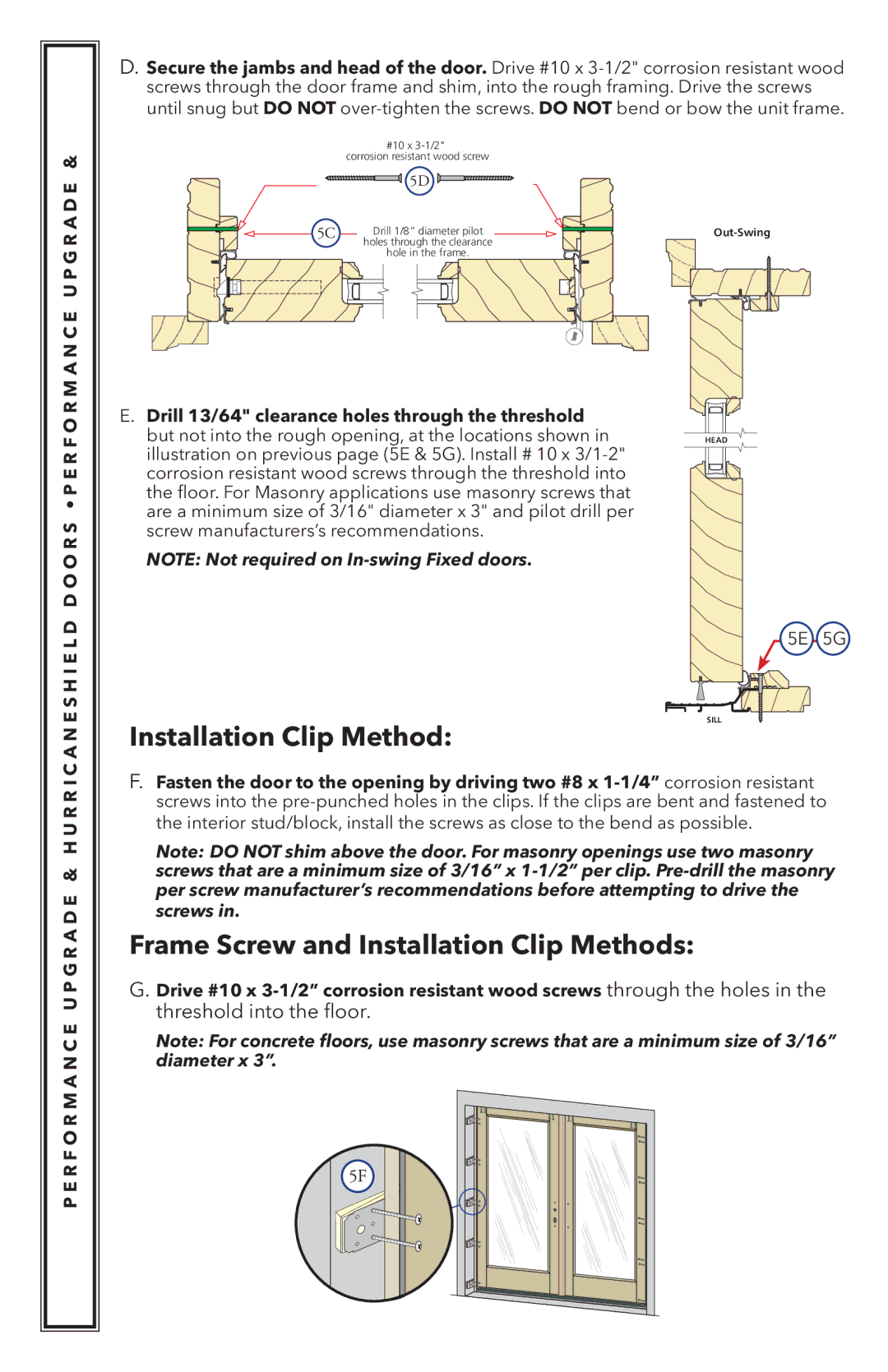

D.Secure the jambs and head of the door. Drive #10 x

D D O O R S • P E R FAOP R&M HA UN RC RE I UC AP GN RE AS HD IEE L&D

| #10 x |

| corrosion resistant wood screw |

| 5D |

5C | Drill 1/8” diameter pilot |

| holes through the clearance |

hole in the frame.

E.Drill 13/64" clearance holes through the threshold but not into the rough opening, at the locations shown in illustration on previous page (5E & 5G). Install # 10 x

NOTE: Not required on

HEAD

P E R F O R M A N C E U P G R A D E & H U R R I C A N E S H I E L

5E 5G

SILL

Installation Clip Method:

F.Fasten the door to the opening by driving two #8 x

Note: DO NOT shim above the door. For masonry openings use two masonry screws that are a minimum size of 3/16” x

Frame Screw and Installation Clip Methods:

G.Drive #10 x

Note: For concrete floors, use masonry screws that are a minimum size of 3/16” diameter x 3”.

5F