|

|

|

|

|

| risk from noise |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

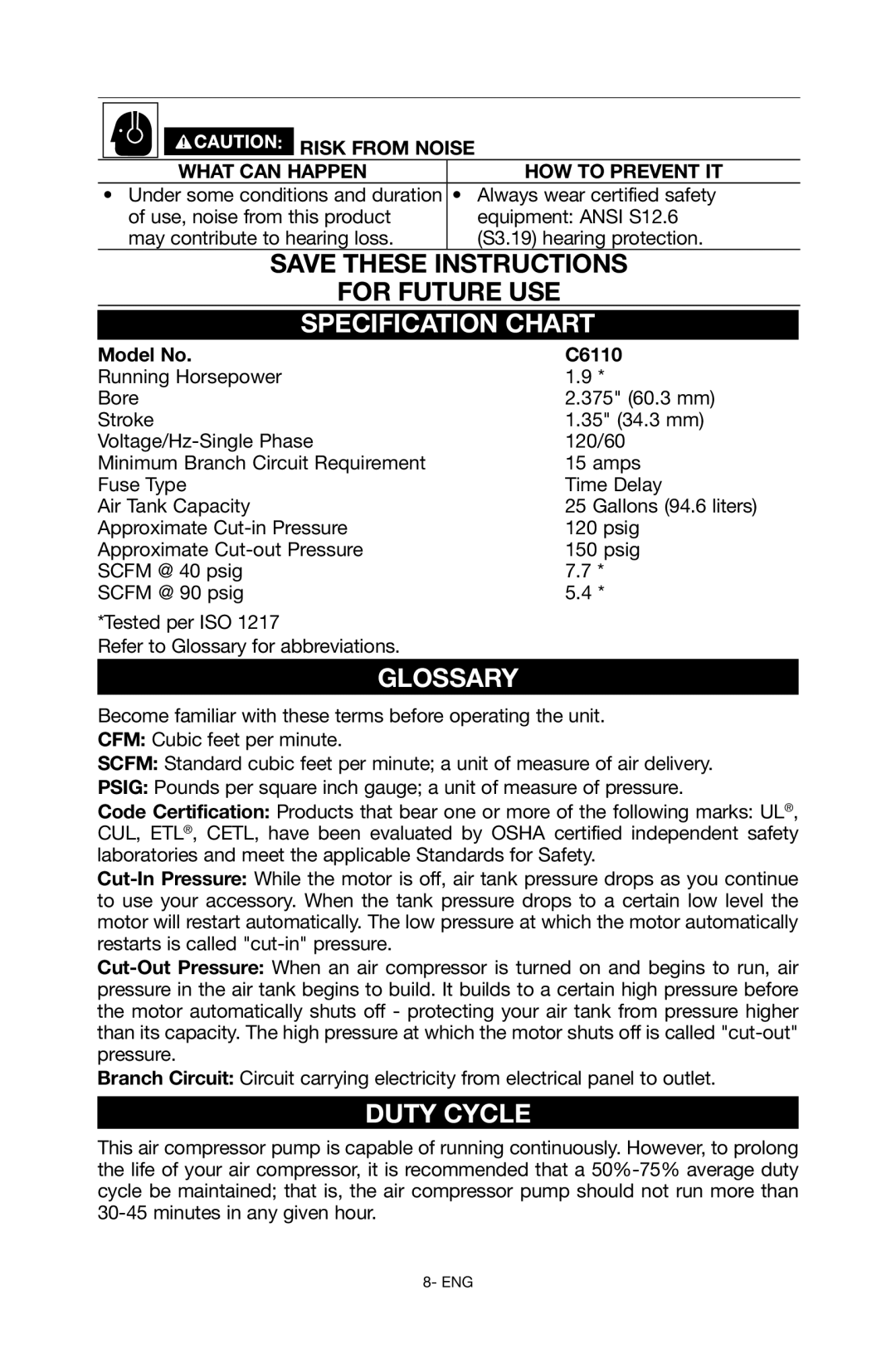

| What can happen | How to prevent it | |||

| • Under some conditions and duration • | Always wear certified safety | |||||

| of use, noise from this product | equipment: ANSI S12.6 | |||||

| may contribute to hearing loss. | (S3.19) hearing protection. | |||||

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

SPECIFICATION CHART

Model No. | C6110 |

Running Horsepower | 1.9 * |

Bore | 2.375" (60.3 mm) |

Stroke | 1.35" (34.3 mm) |

120/60 | |

Minimum Branch Circuit Requirement | 15 amps |

Fuse Type | Time Delay |

Air Tank Capacity | 25 Gallons (94.6 liters) |

Approximate | 120 psig |

Approximate | 150 psig |

SCFM @ 40 psig | 7.7 * |

SCFM @ 90 psig | 5.4 * |

*Tested per ISO 1217

Refer to Glossary for abbreviations.

GLOSSARY

Become familiar with these terms before operating the unit. CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSIG: Pounds per square inch gauge; a unit of measure of pressure.

Code Certification: Products that bear one or more of the following marks: UL®, CUL, ETL®, CETL, have been evaluated by OSHA certified independent safety laboratories and meet the applicable Standards for Safety.

Branch Circuit: Circuit carrying electricity from electrical panel to outlet.

DUTY CYCLE

This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor, it is recommended that a

8- ENG