Infeed Roller

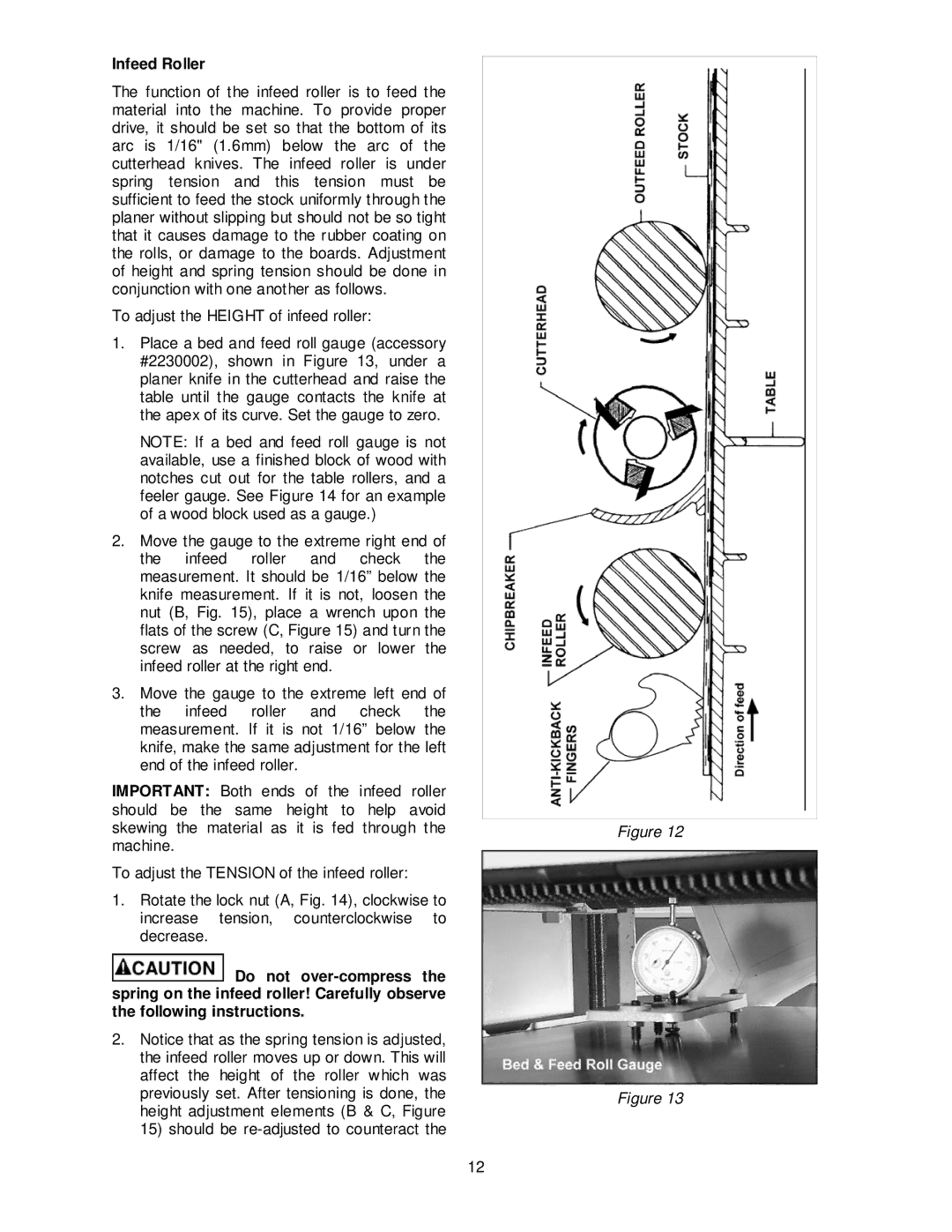

The function of the infeed roller is to feed the material into the machine. To provide proper drive, it should be set so that the bottom of its arc is 1/16" (1.6mm) below the arc of the cutterhead knives. The infeed roller is under spring tension and this tension must be sufficient to feed the stock uniformly through the planer without slipping but should not be so tight that it causes damage to the rubber coating on the rolls, or damage to the boards. Adjustment of height and spring tension should be done in conjunction with one another as follows.

To adjust the HEIGHT of infeed roller:

1.Place a bed and feed roll gauge (accessory #2230002), shown in Figure 13, under a planer knife in the cutterhead and raise the table until the gauge contacts the knife at the apex of its curve. Set the gauge to zero.

NOTE: If a bed and feed roll gauge is not available, use a finished block of wood with notches cut out for the table rollers, and a feeler gauge. See Figure 14 for an example of a wood block used as a gauge.)

2.Move the gauge to the extreme right end of the infeed roller and check the measurement. It should be 1/16” below the knife measurement. If it is not, loosen the nut (B, Fig. 15), place a wrench upon the flats of the screw (C, Figure 15) and turn the screw as needed, to raise or lower the infeed roller at the right end.

3.Move the gauge to the extreme left end of the infeed roller and check the measurement. If it is not 1/16” below the knife, make the same adjustment for the left end of the infeed roller.

IMPORTANT: Both ends of the infeed roller should be the same height to help avoid skewing the material as it is fed through the machine.

To adjust the TENSION of the infeed roller:

1.Rotate the lock nut (A, Fig. 14), clockwise to increase tension, counterclockwise to decrease.

![]() Do not

Do not

2.Notice that as the spring tension is adjusted, the infeed roller moves up or down. This will affect the height of the roller which was previously set. After tensioning is done, the height adjustment elements (B & C, Figure

15)should be

Figure 12

Figure 13

12