4.Install one steel gib and the steel counterweight in the second slot. Tighten the gib set screws. (The steel gib and counterweight are ground to balance the cutterhead.) See Figure 30.

5.Install the other steel gib and counterweight in the third slot and tighten the gib set screws.

![]() Do not interchange counter- weights between sets of pattern knives. They are properly sized for the one set. Machine vibration may result if counterweights are accidentally interchanged.

Do not interchange counter- weights between sets of pattern knives. They are properly sized for the one set. Machine vibration may result if counterweights are accidentally interchanged.

Installing Three-Knife Set

1.Loosen the set screws on the gib in the first slot. Tap the gib down to release the planer knives.

2.Insert the pattern knife next to the planer knife, as shown in Figure 31. Note: Small molder knives (1” and under) will require a spacer.

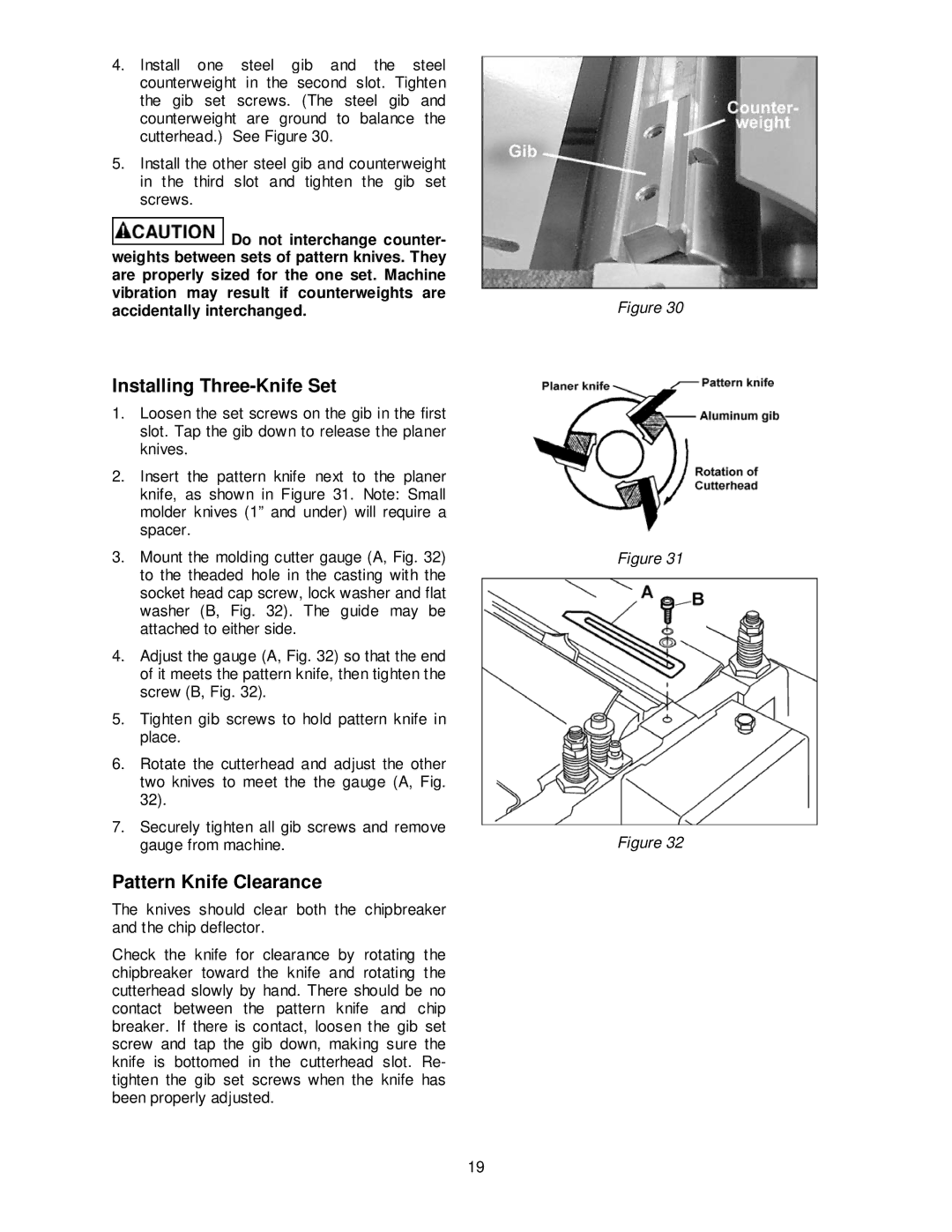

3.Mount the molding cutter gauge (A, Fig. 32) to the theaded hole in the casting with the socket head cap screw, lock washer and flat washer (B, Fig. 32). The guide may be attached to either side.

4.Adjust the gauge (A, Fig. 32) so that the end of it meets the pattern knife, then tighten the screw (B, Fig. 32).

5.Tighten gib screws to hold pattern knife in place.

6.Rotate the cutterhead and adjust the other two knives to meet the the gauge (A, Fig. 32).

7.Securely tighten all gib screws and remove gauge from machine.

Pattern Knife Clearance

The knives should clear both the chipbreaker and the chip deflector.

Check the knife for clearance by rotating the chipbreaker toward the knife and rotating the cutterhead slowly by hand. There should be no contact between the pattern knife and chip breaker. If there is contact, loosen the gib set screw and tap the gib down, making sure the knife is bottomed in the cutterhead slot. Re- tighten the gib set screws when the knife has been properly adjusted.

Figure 30

Figure 31

Figure 32

19