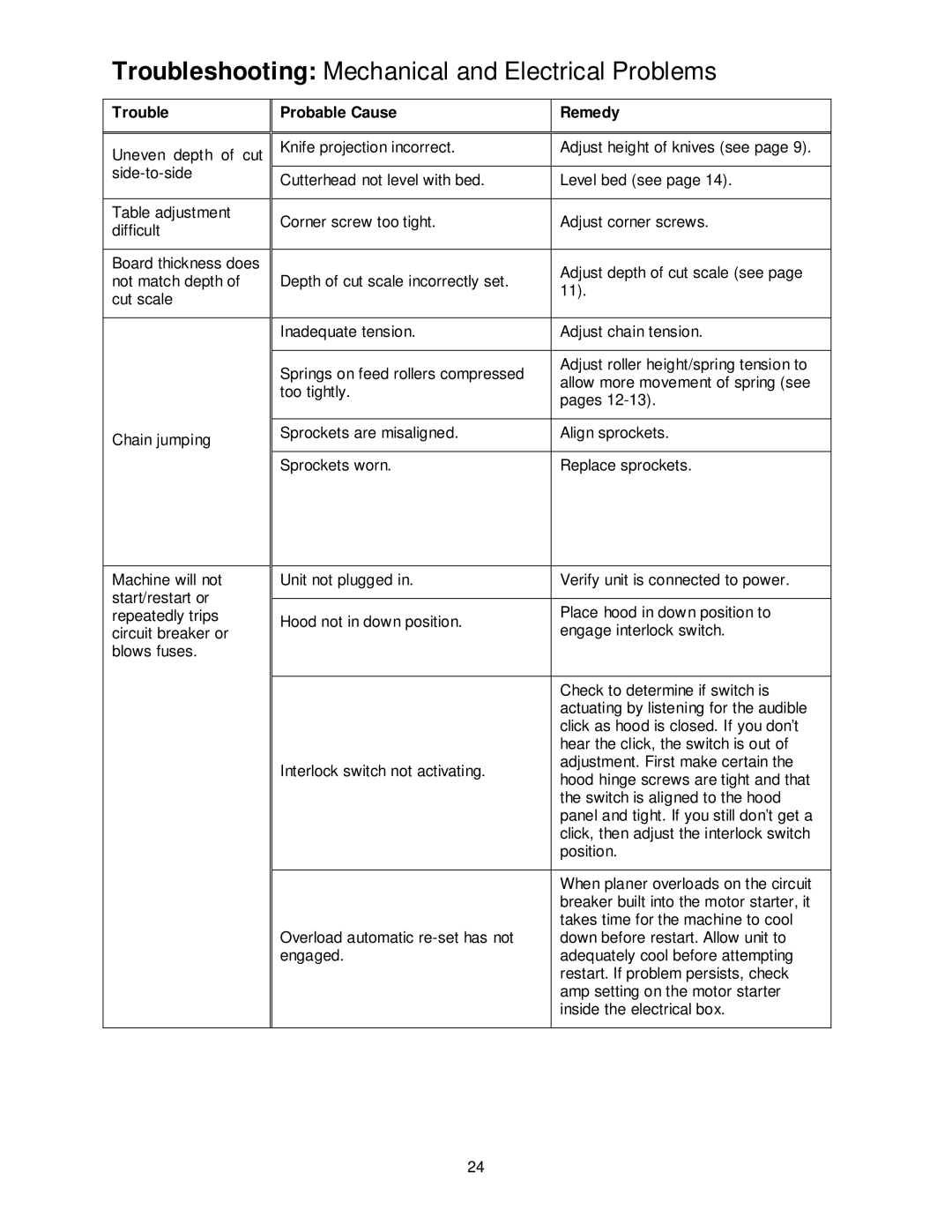

Troubleshooting: Mechanical and Electrical Problems

Trouble

Uneven depth of cut

Table adjustment difficult

Board thickness does not match depth of cut scale

Chain jumping

Machine will not start/restart or repeatedly trips circuit breaker or blows fuses.

Probable Cause | Remedy | |

|

| |

|

| |

Knife projection incorrect. | Adjust height of knives (see page 9). | |

|

| |

Cutterhead not level with bed. | Level bed (see page 14). | |

|

| |

Corner screw too tight. | Adjust corner screws. | |

|

| |

Depth of cut scale incorrectly set. | Adjust depth of cut scale (see page | |

11). | ||

| ||

|

| |

Inadequate tension. | Adjust chain tension. | |

|

| |

Springs on feed rollers compressed | Adjust roller height/spring tension to | |

allow more movement of spring (see | ||

too tightly. | ||

pages | ||

| ||

|

| |

Sprockets are misaligned. | Align sprockets. | |

|

| |

Sprockets worn. | Replace sprockets. | |

|

| |

Unit not plugged in. | Verify unit is connected to power. | |

|

| |

Hood not in down position. | Place hood in down position to | |

engage interlock switch. | ||

| ||

|

| |

| Check to determine if switch is | |

| actuating by listening for the audible | |

| click as hood is closed. If you don’t | |

| hear the click, the switch is out of | |

Interlock switch not activating. | adjustment. First make certain the | |

hood hinge screws are tight and that | ||

| ||

| the switch is aligned to the hood | |

| panel and tight. If you still don’t get a | |

| click, then adjust the interlock switch | |

| position. | |

|

| |

| When planer overloads on the circuit | |

| breaker built into the motor starter, it | |

| takes time for the machine to cool | |

Overload automatic | down before restart. Allow unit to | |

engaged. | adequately cool before attempting | |

| restart. If problem persists, check | |

| amp setting on the motor starter | |

| inside the electrical box. | |

|

|

24