Rabbet

A rabbet is a rectangular cut on the corner of a molding, as shown in Figure 38.

It is commonly used where pieces of wood are being butted against and/or overlapped, such as in ship lap and bevel siding. Always set your guide against the side being rabbeted. The rabbet cut should be completed before the exposed side of the molding is finished.

Parting Bits

Parting bits will do a very smooth job of sawing soft wood up to 3/4” thick. They are installed the same as custom pattern knives with the planer blades removed. More than one parting bit may be used at one time. They can be placed as close as 3/4” apart, and up to

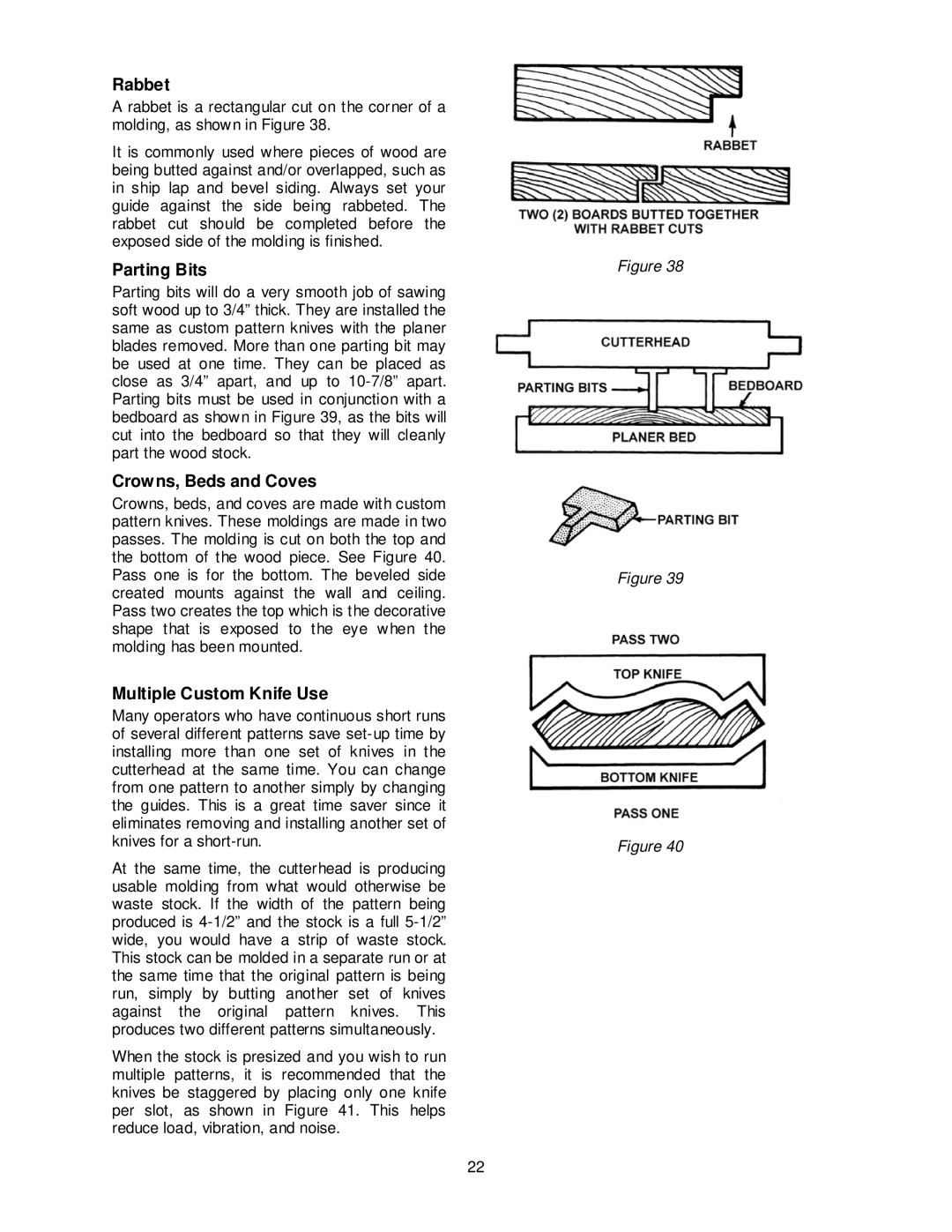

Crowns, Beds and Coves

Crowns, beds, and coves are made with custom pattern knives. These moldings are made in two passes. The molding is cut on both the top and the bottom of the wood piece. See Figure 40. Pass one is for the bottom. The beveled side created mounts against the wall and ceiling. Pass two creates the top which is the decorative shape that is exposed to the eye when the molding has been mounted.

Multiple Custom Knife Use

Many operators who have continuous short runs of several different patterns save

At the same time, the cutterhead is producing usable molding from what would otherwise be waste stock. If the width of the pattern being produced is

When the stock is presized and you wish to run multiple patterns, it is recommended that the knives be staggered by placing only one knife per slot, as shown in Figure 41. This helps reduce load, vibration, and noise.

22

Figure 38

Figure 39

Figure 40