Miter Gauge and Clamp

Mount miter gauge and clamp to the sliding table as follows:

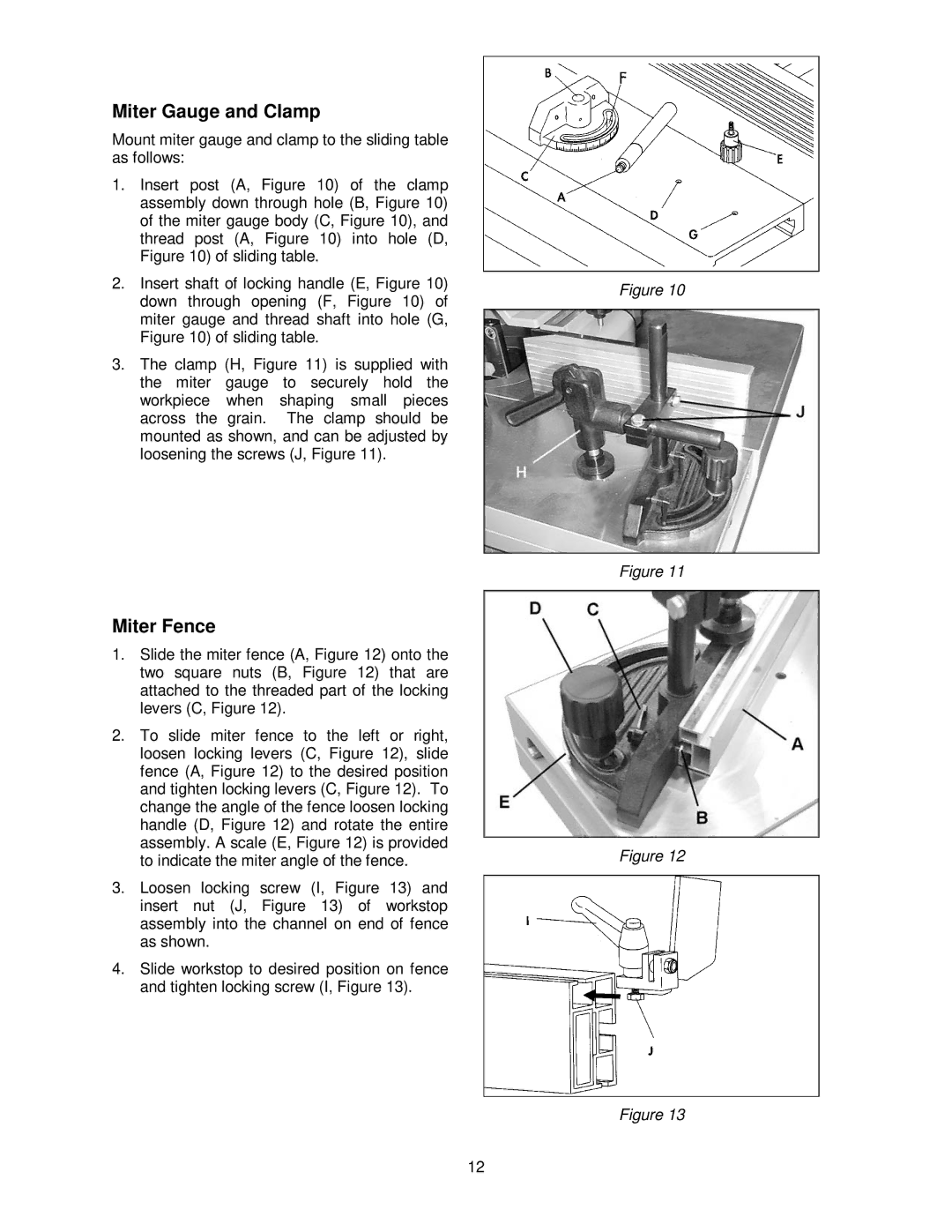

1.Insert post (A, Figure 10) of the clamp assembly down through hole (B, Figure 10) of the miter gauge body (C, Figure 10), and thread post (A, Figure 10) into hole (D, Figure 10) of sliding table.

2.Insert shaft of locking handle (E, Figure 10) down through opening (F, Figure 10) of miter gauge and thread shaft into hole (G, Figure 10) of sliding table.

3.The clamp (H, Figure 11) is supplied with the miter gauge to securely hold the workpiece when shaping small pieces across the grain. The clamp should be mounted as shown, and can be adjusted by loosening the screws (J, Figure 11).

Miter Fence

1.Slide the miter fence (A, Figure 12) onto the two square nuts (B, Figure 12) that are attached to the threaded part of the locking levers (C, Figure 12).

2.To slide miter fence to the left or right, loosen locking levers (C, Figure 12), slide fence (A, Figure 12) to the desired position and tighten locking levers (C, Figure 12). To change the angle of the fence loosen locking handle (D, Figure 12) and rotate the entire assembly. A scale (E, Figure 12) is provided to indicate the miter angle of the fence.

3.Loosen locking screw (I, Figure 13) and insert nut (J, Figure 13) of workstop assembly into the channel on end of fence as shown.

4.Slide workstop to desired position on fence and tighten locking screw (I, Figure 13).

12

Figure 10

Figure 11

Figure 12

Figure 13