2.When the shaping operation removes the entire edge of the stock, e.g. in jointing or making a full bead, the shaped edge will not be supported by the outfeed fence when both fences are in line, as shown in Figure 27. In this case, the stock should be advanced to the position shown in Figure 27 and stopped. The outfeed fence should then be moved forward to contact the work, as shown in Figure 28. The outfeed fence will then be in line with the cutting circle, and the operation can continue.

![]() Keep guards in place and in working order. Always use fence assembly when the work permits.

Keep guards in place and in working order. Always use fence assembly when the work permits.

Position of Collars

When shaping with collars, the collar must have sufficient bearing surface, as shown in Figure

29.The workpiece must also be fairly heavy relative to the cut being made. Under no circumstances should a short, light workpiece be shaped against the collars, as shown in Figure

The collars may be used in any of the following positions: above, below, or between the cutters.

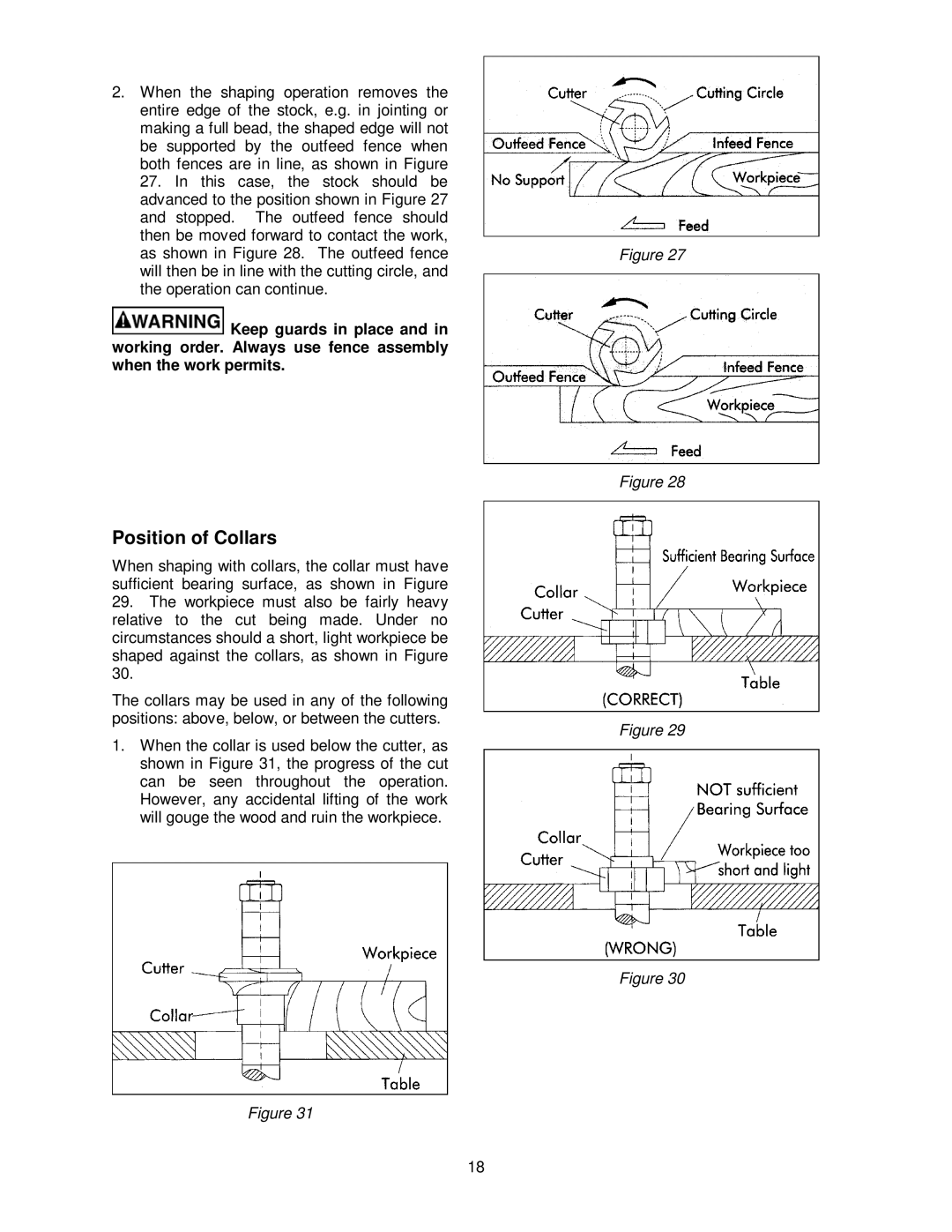

1.When the collar is used below the cutter, as shown in Figure 31, the progress of the cut can be seen throughout the operation. However, any accidental lifting of the work will gouge the wood and ruin the workpiece.

Figure 31

18

Figure 27

Figure 28

Figure 29

Figure 30