3.Another technique is to install an air detection sensor in the suction port area, so that the auto valve is automatically opened by a signal sent out from the sensor and the air elimination operation is initiated.

5 INSTALLATION, PIPING & WIRING

5.1Installation

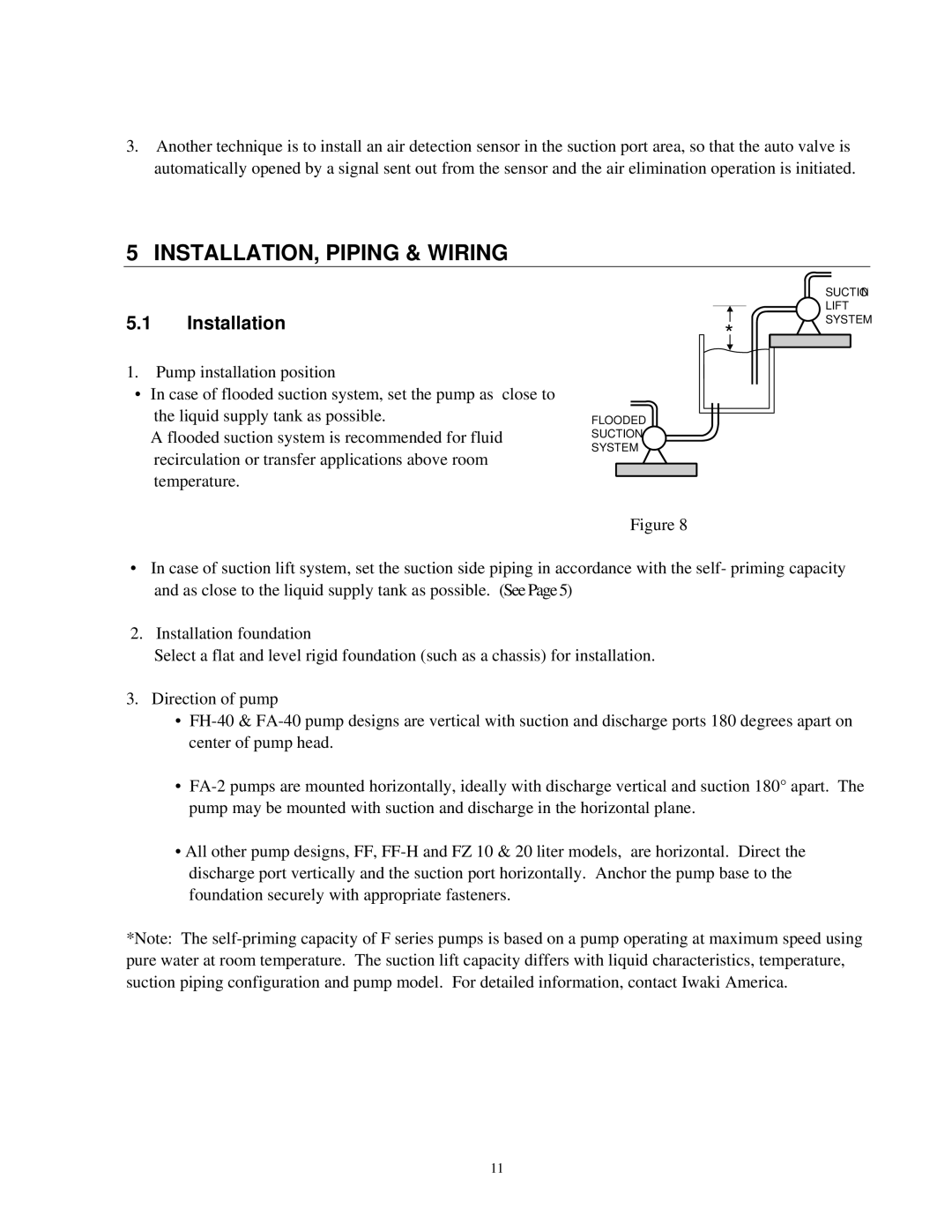

1.Pump installation position

•In case of flooded suction system, set the pump as close to the liquid supply tank as possible.

A flooded suction system is recommended for fluid recirculation or transfer applications above room temperature.

*

FLOODED

SUCTION

SYSTEM

Figure 8

SUCTION LIFT SYSTEM

•In case of suction lift system, set the suction side piping in accordance with the self- priming capacity and as close to the liquid supply tank as possible. (See Page 5)

2. Installation foundation

Select a flat and level rigid foundation (such as a chassis) for installation.

3.Direction of pump

•

•

•All other pump designs, FF,

*Note: The

11