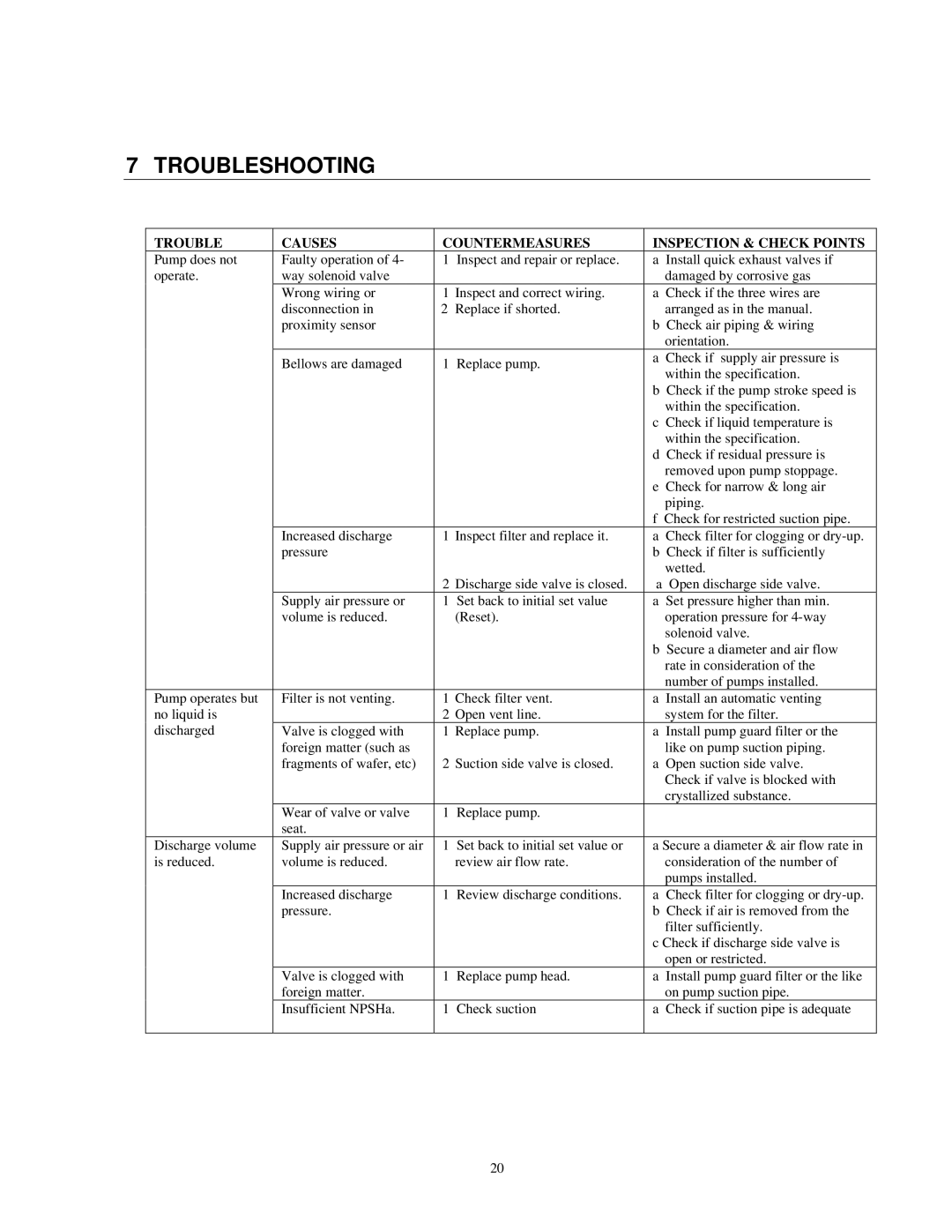

7 TROUBLESHOOTING

TROUBLE | CAUSES | COUNTERMEASURES | |

Pump does not | Faulty operation of 4- | 1 | Inspect and repair or replace. |

operate. | way solenoid valve |

|

|

| Wrong wiring or | 1 | Inspect and correct wiring. |

| disconnection in | 2 | Replace if shorted. |

| proximity sensor |

|

|

|

|

|

|

| Bellows are damaged | 1 | Replace pump. |

| Increased discharge | 1 | Inspect filter and replace it. |

| pressure |

|

|

|

| 2 | Discharge side valve is closed. |

| Supply air pressure or | 1 | Set back to initial set value |

| volume is reduced. |

| (Reset). |

|

|

|

|

Pump operates but | Filter is not venting. | 1 | Check filter vent. |

no liquid is |

| 2 | Open vent line. |

discharged | Valve is clogged with | 1 | Replace pump. |

| foreign matter (such as |

|

|

| fragments of wafer, etc) | 2 | Suction side valve is closed. |

|

|

|

|

| Wear of valve or valve | 1 | Replace pump. |

| seat. |

|

|

Discharge volume | Supply air pressure or air | 1 | Set back to initial set value or |

is reduced. | volume is reduced. |

| review air flow rate. |

|

|

|

|

| Increased discharge | 1 | Review discharge conditions. |

| pressure. |

|

|

|

|

|

|

| Valve is clogged with | 1 | Replace pump head. |

| foreign matter. |

|

|

| Insufficient NPSHa. | 1 | Check suction |

20

INSPECTION & CHECK POINTS

aInstall quick exhaust valves if damaged by corrosive gas

aCheck if the three wires are arranged as in the manual.

bCheck air piping & wiring orientation.

aCheck if supply air pressure is within the specification.

bCheck if the pump stroke speed is within the specification.

cCheck if liquid temperature is within the specification.

dCheck if residual pressure is removed upon pump stoppage.

eCheck for narrow & long air piping.

fCheck for restricted suction pipe.

aCheck filter for clogging or

bCheck if filter is sufficiently wetted.

aOpen discharge side valve. a Set pressure higher than min. operation pressure for

solenoid valve.

b Secure a diameter and air flow rate in consideration of the number of pumps installed.

a Install an automatic venting system for the filter.

a Install pump guard filter or the

like on pump suction piping. a Open suction side valve.

Check if valve is blocked with crystallized substance.

a Secure a diameter & air flow rate in consideration of the number of pumps installed.

aCheck filter for clogging or

bCheck if air is removed from the filter sufficiently.

cCheck if discharge side valve is open or restricted.

aInstall pump guard filter or the like on pump suction pipe.

a Check if suction pipe is adequate