Systems with multiple zones may require an additional circulator. Consult manufacturers data for valve pressure drops. When an indirect water heating system is used, it is recommended that a separate circulator be installed to meet the required flow and pressure drop conditions of the indirect water heater.

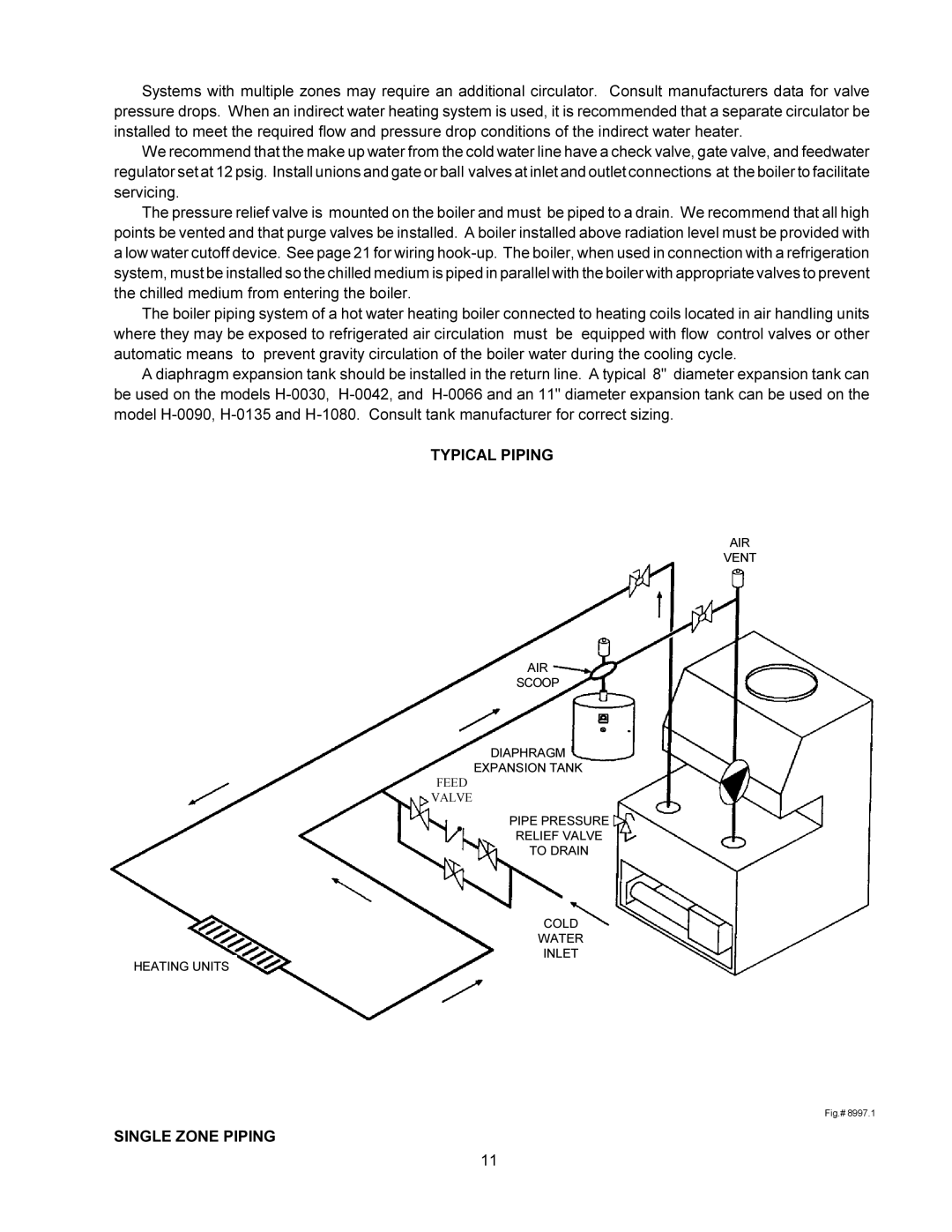

We recommend that the make up water from the cold water line have a check valve, gate valve, and feedwater regulator set at 12 psig. Install unions and gate or ball valves at inlet and outlet connections at the boiler to facilitate servicing.

The pressure relief valve is mounted on the boiler and must be piped to a drain. We recommend that all high points be vented and that purge valves be installed. A boiler installed above radiation level must be provided with a low water cutoff device. See page 21 for wiring

The boiler piping system of a hot water heating boiler connected to heating coils located in air handling units where they may be exposed to refrigerated air circulation must be equipped with flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle.

A diaphragm expansion tank should be installed in the return line. A typical 8" diameter expansion tank can be used on the models

TYPICAL PIPING

AIR

VENT

AIR

SCOOP

DIAPHRAGM

EXPANSION TANK

FEED

VALVE

PIPE PRESSURE

RELIEF VALVE

TO DRAIN

COLD

WATER

INLET

HEATING UNITS

Fig.# 8997.1

SINGLE ZONE PIPING

11