ELECTRICAL WIRING

The electrical power supply requirement for these boilers is 115 volts, 60 Hz. Field wiring connections and electrical grounding must comply with the local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA

Remove the control box cover and make the power supply connections in the field wiring compartment. (See general location of controls drawing on page 18). The pump is supplied and factory wired to operate with the boiler. The "TH" wire leads are for the room thermostat or zone valve connections.

The room thermostat should be installed in accordance with the manufacturer's instructions. The thermostat heat anticipator should be set at 1.0 ampere (automatic ignition) and 0.60 ampere (standing pilot) for single zone installations. For

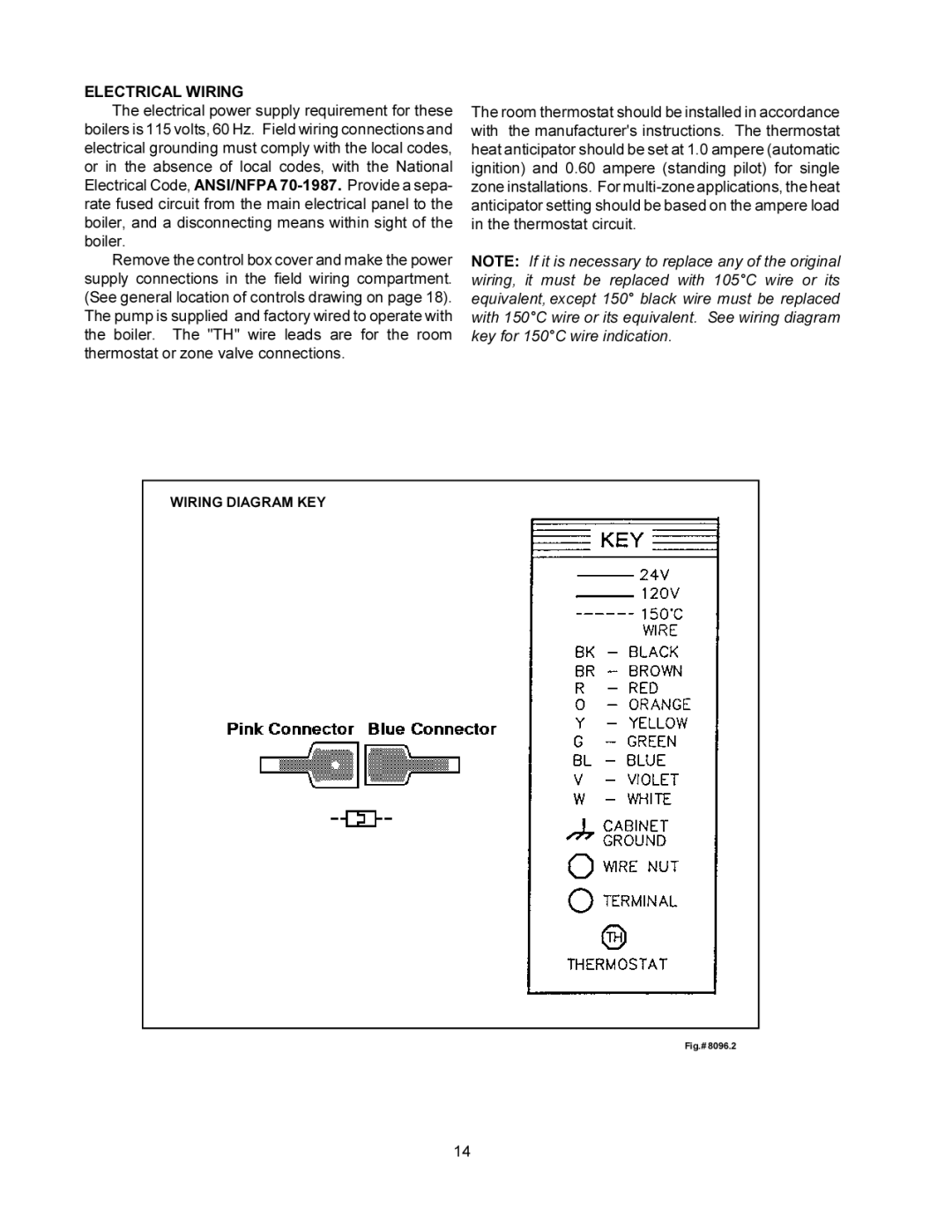

NOTE: If it is necessary to replace any of the original wiring, it must be replaced with 105°C wire or its equivalent, except 150° black wire must be replaced with 150°C wire or its equivalent. See wiring diagram key for 150°C wire indication.

WIRING DIAGRAM KEY

Fig.# 8096.2

14