Selecting Power

Fasteners and

Powder Loads

FASTENING INTO CONCRETE

The proper power fastener length can be determined by adding the thickness of the material to be fas- tened and the amount of fastener that will actually penetrate the con- crete. The concrete must be three times as thick as the intended fas- tener penetration. In most cases, penetration should be approxi- mately 1" to 1 1/4" into the base concrete material.

FASTENING INTO STEEL

The proper fastener length can be determined by adding the thick- ness of the material to be fastened and the thickness of the steel. The point of the power fastener must go completely through the steel.

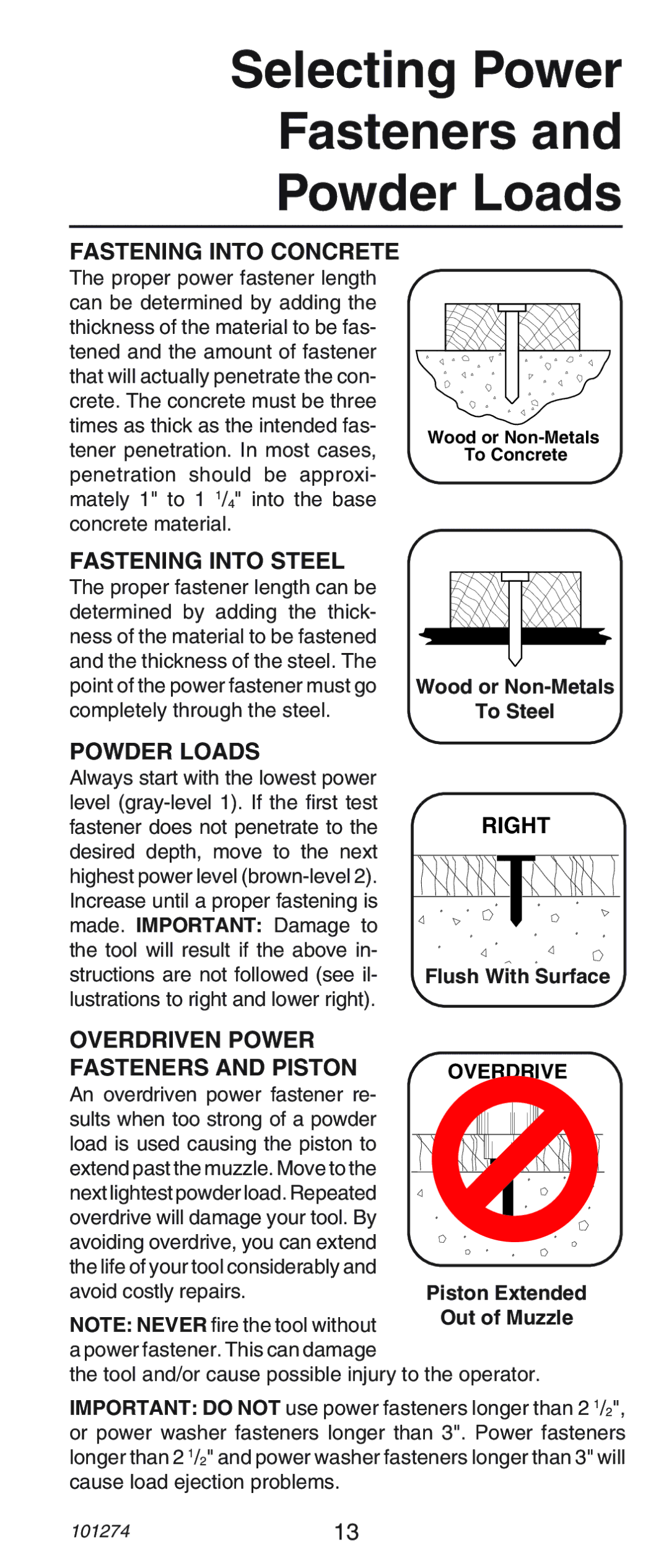

POWDER LOADS

Always start with the lowest power level

OVERDRIVEN POWER

FASTENERS AND PISTON

An overdriven power fastener re- sults when too strong of a powder load is used causing the piston to extend past the muzzle. Move to the next lightest powder load. Repeated overdrive will damage your tool. By avoiding overdrive, you can extend the life of your tool considerably and avoid costly repairs.

NOTE: NEVER fire the tool without a power fastener. This can damage

the tool and/or cause possible injury to the operator.

IMPORTANT: DO NOT use power fasteners longer than 2 1/2", or power washer fasteners longer than 3". Power fasteners longer than 2 1/2" and power washer fasteners longer than 3" will cause load ejection problems.

101274 | 13 |