SAFETY

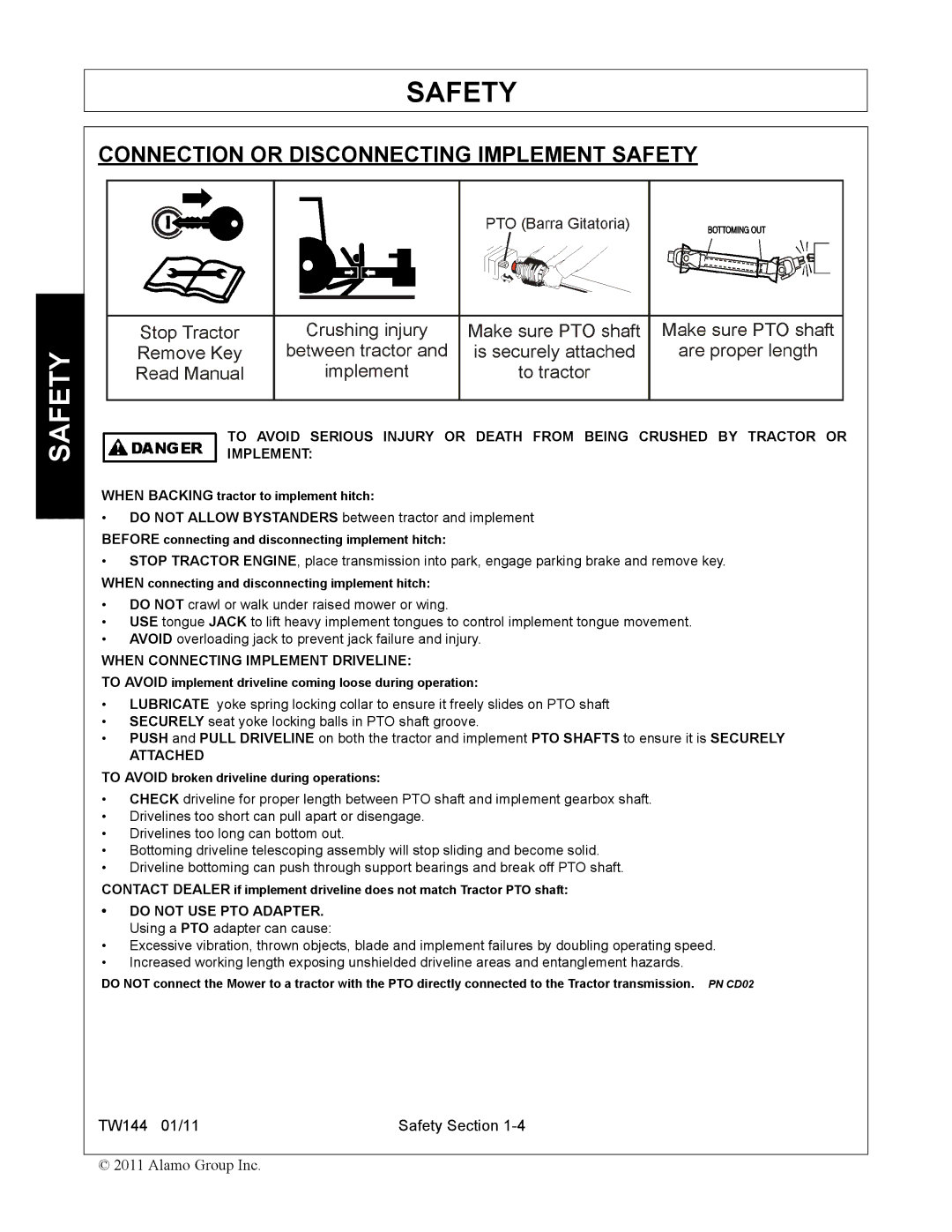

CONNECTION OR DISCONNECTING IMPLEMENT SAFETY

SAFETY

TO AVOID SERIOUS INJURY OR DEATH FROM BEING CRUSHED BY TRACTOR OR IMPLEMENT:

WHEN BACKING tractor to implement hitch:

•DO NOT ALLOW BYSTANDERS between tractor and implement

BEFORE connecting and disconnecting implement hitch:

•STOP TRACTOR ENGINE, place transmission into park, engage parking brake and remove key.

WHEN connecting and disconnecting implement hitch:

•DO NOT crawl or walk under raised mower or wing.

•USE tongue JACK to lift heavy implement tongues to control implement tongue movement.

•AVOID overloading jack to prevent jack failure and injury.

WHEN CONNECTING IMPLEMENT DRIVELINE:

TO AVOID implement driveline coming loose during operation:

•LUBRICATE yoke spring locking collar to ensure it freely slides on PTO shaft

•SECURELY seat yoke locking balls in PTO shaft groove.

•PUSH and PULL DRIVELINE on both the tractor and implement PTO SHAFTS to ensure it is SECURELY

ATTACHED

TO AVOID broken driveline during operations:

•CHECK driveline for proper length between PTO shaft and implement gearbox shaft.

•Drivelines too short can pull apart or disengage.

•Drivelines too long can bottom out.

•Bottoming driveline telescoping assembly will stop sliding and become solid.

•Driveline bottoming can push through support bearings and break off PTO shaft.

CONTACT DEALER if implement driveline does not match Tractor PTO shaft:

•DO NOT USE PTO ADAPTER. Using a PTO adapter can cause:

•Excessive vibration, thrown objects, blade and implement failures by doubling operating speed.

•Increased working length exposing unshielded driveline areas and entanglement hazards.

DO NOT connect the Mower to a tractor with the PTO directly connected to the Tractor transmission. PN CD02

TW144 01/11 | Safety Section |

© 2011 Alamo Group Inc.