Assembly (continued)

![]() WARNING: For your own safety turn switch “OFF” and remove plug from power source outlet before making any adjustments. To reduce the risk of injury from thrown parts due to spring release, follow instructions carefully and wear eye goggles.

WARNING: For your own safety turn switch “OFF” and remove plug from power source outlet before making any adjustments. To reduce the risk of injury from thrown parts due to spring release, follow instructions carefully and wear eye goggles.

Quill Return Spring

NOTE: The return spring tension is set at the factory and should not require further adjustment.

If you switched your drill press from right hand operation to left hand operation, fol- low the procedure below to adjust spring tension.

1.With the chuck at its highest possible position, turn the depth scale clockwise until it stops and tighten the depth scale lock. This will prevent the quill from dropping while tensioning the spring.

NOTE: For right hand operation (feed handle on right side) turn the depth scale counterclockwise until it stops and tighten the depth scale lock.

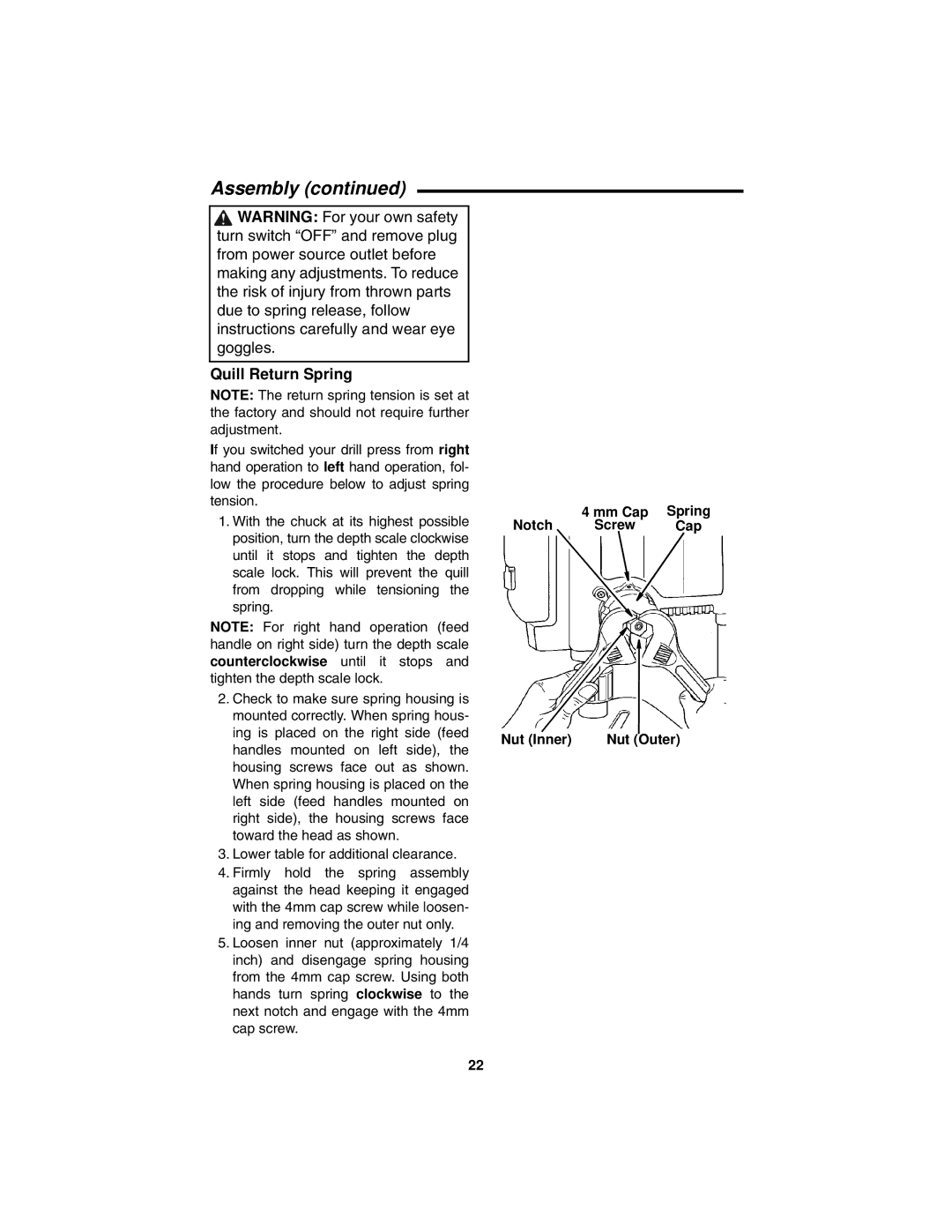

2.Check to make sure spring housing is mounted correctly. When spring hous- ing is placed on the right side (feed handles mounted on left side), the housing screws face out as shown. When spring housing is placed on the left side (feed handles mounted on right side), the housing screws face toward the head as shown.

3.Lower table for additional clearance.

4.Firmly hold the spring assembly against the head keeping it engaged with the 4mm cap screw while loosen- ing and removing the outer nut only.

5.Loosen inner nut (approximately 1/4 inch) and disengage spring housing from the 4mm cap screw. Using both hands turn spring clockwise to the next notch and engage with the 4mm cap screw.

| 4 mm Cap | Spring |

Notch | Screw | Cap |

Nut (Inner) | Nut (Outer) |

22