to allow cutter to work through the obstruction. If motor turns but the drum stops, the torque limiter is slipping because of excessive force. Pull back on cable to relieve torque and drum will begin to spin.

TIP: If cable continues to get hung up in blockage, dis- continue use of the auto feed and work cable by hand.

7.Once flow is established, use running water to wash debris and roots down the drain while finishing the job.

![]() WARNING

WARNING

Do not allow tension to build up in the cable. This will happen if the cutting tool hits a snag and stops turning, but the motor and its drum continue to ro- tate. Torque builds until the cable suddenly twists, potentially wrapping around your hand or arm. This can happen quickly and without warning, so proceed slowly and carefully as you feed the cable into the drain. If tool gets hung up in an obstruction, refer to Reverse Operating Instructions in the “Special Procedures” section.

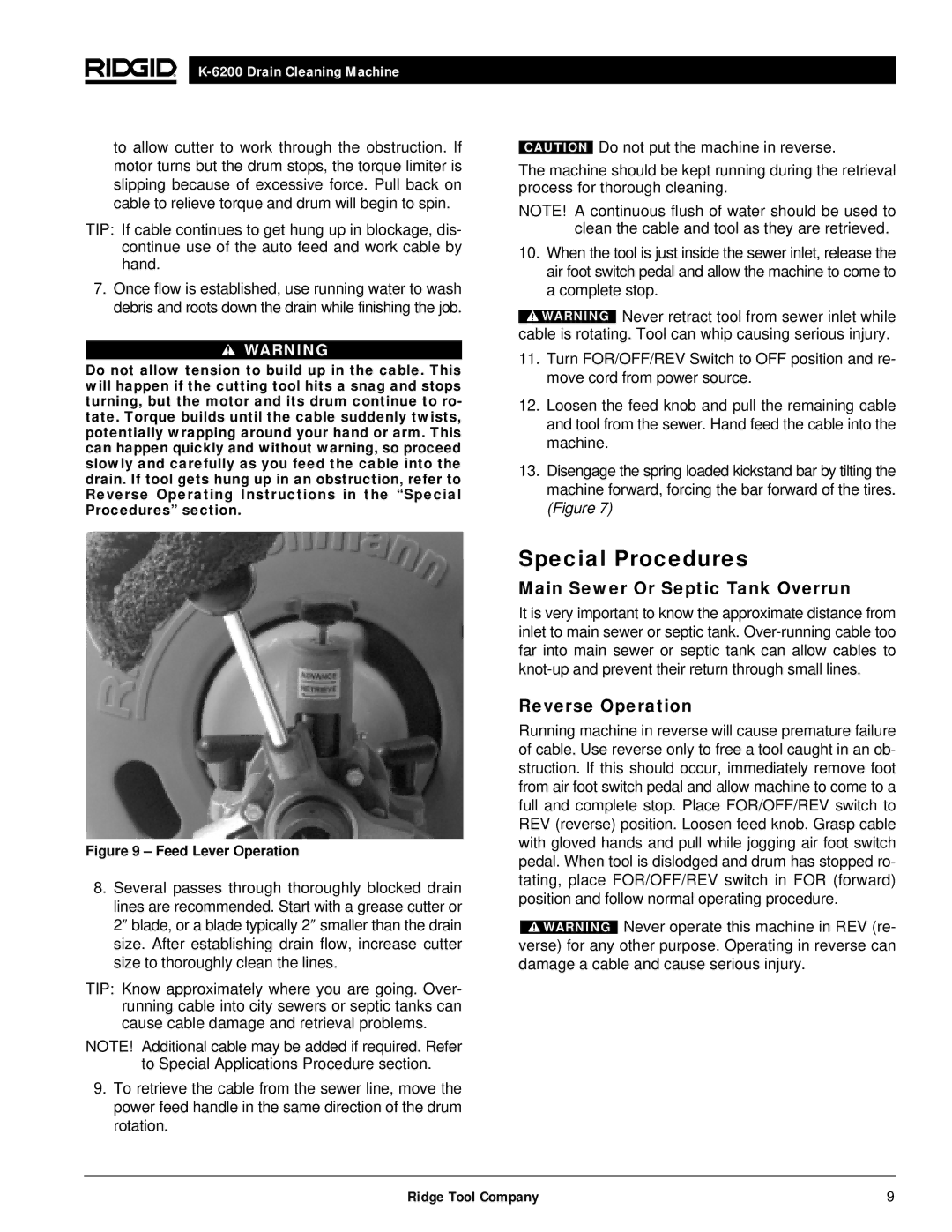

Figure 9 – Feed Lever Operation

8.Several passes through thoroughly blocked drain lines are recommended. Start with a grease cutter or 2″ blade, or a blade typically 2″ smaller than the drain size. After establishing drain flow, increase cutter size to thoroughly clean the lines.

TIP: Know approximately where you are going. Over- running cable into city sewers or septic tanks can cause cable damage and retrieval problems.

NOTE! Additional cable may be added if required. Refer to Special Applications Procedure section.

9.To retrieve the cable from the sewer line, move the power feed handle in the same direction of the drum rotation.

CAUTION Do not put the machine in reverse.

The machine should be kept running during the retrieval process for thorough cleaning.

NOTE! A continuous flush of water should be used to clean the cable and tool as they are retrieved.

10.When the tool is just inside the sewer inlet, release the air foot switch pedal and allow the machine to come to a complete stop.

![]() WARNING Never retract tool from sewer inlet while cable is rotating. Tool can whip causing serious injury.

WARNING Never retract tool from sewer inlet while cable is rotating. Tool can whip causing serious injury.

11.Turn FOR/OFF/REV Switch to OFF position and re- move cord from power source.

12.Loosen the feed knob and pull the remaining cable and tool from the sewer. Hand feed the cable into the machine.

13.Disengage the spring loaded kickstand bar by tilting the machine forward, forcing the bar forward of the tires. (Figure 7)

Special Procedures

Main Sewer Or Septic Tank Overrun

It is very important to know the approximate distance from inlet to main sewer or septic tank.

Reverse Operation

Running machine in reverse will cause premature failure of cable. Use reverse only to free a tool caught in an ob- struction. If this should occur, immediately remove foot from air foot switch pedal and allow machine to come to a full and complete stop. Place FOR/OFF/REV switch to REV (reverse) position. Loosen feed knob. Grasp cable with gloved hands and pull while jogging air foot switch pedal. When tool is dislodged and drum has stopped ro- tating, place FOR/OFF/REV switch in FOR (forward) position and follow normal operating procedure.

![]() WARNING Never operate this machine in REV (re- verse) for any other purpose. Operating in reverse can damage a cable and cause serious injury.

WARNING Never operate this machine in REV (re- verse) for any other purpose. Operating in reverse can damage a cable and cause serious injury.

Ridge Tool Company | 9 |