CAP001/A specifications

Saeco Coffee Makers CAP001/A is a revolutionary model designed for coffee enthusiasts who appreciate high-quality brewing at the touch of a button. This machine encapsulates Saeco’s commitment to delivering an exceptional coffee experience, combining advanced technologies with user-friendly features.One of the standout attributes of the CAP001/A is its built-in ceramic grinder, which offers precise grinding for a maximum flavor extraction. Unlike metal grinders, ceramic ones maintain stable temperatures, ensuring that the coffee beans are ground without overheating, thus preserving essential oils and aromas. This results in a richer and more aromatic coffee experience.

The CAP001/A is equipped with a one-touch brewing system, allowing users to prepare a variety of coffee drinks effortlessly. From espressos to lattes, the machine caters to diverse tastes and preferences. It features an intuitive display panel, making it simple for anyone to select their desired beverage, adjust coffee strength, and customize the amount of milk or foam as desired.

A significant advantage of this model is the AquaClean water filter integrated into its design. This technology not only enhances the purity of water used for brewing but also significantly reduces the frequency of descaling. With the AquaClean filter, users can enjoy up to 5,000 cups of coffee without worrying about limescale buildup, thereby extending the life of the machine and maintaining its performance.

The CAP001/A also showcases an automatic milk frother, which delivers perfectly frothed milk for a creamy texture, ideal for cappuccinos and macchiatos. The foaming capacity can be adjusted to suit personal preferences, making it versatile for different drinks.

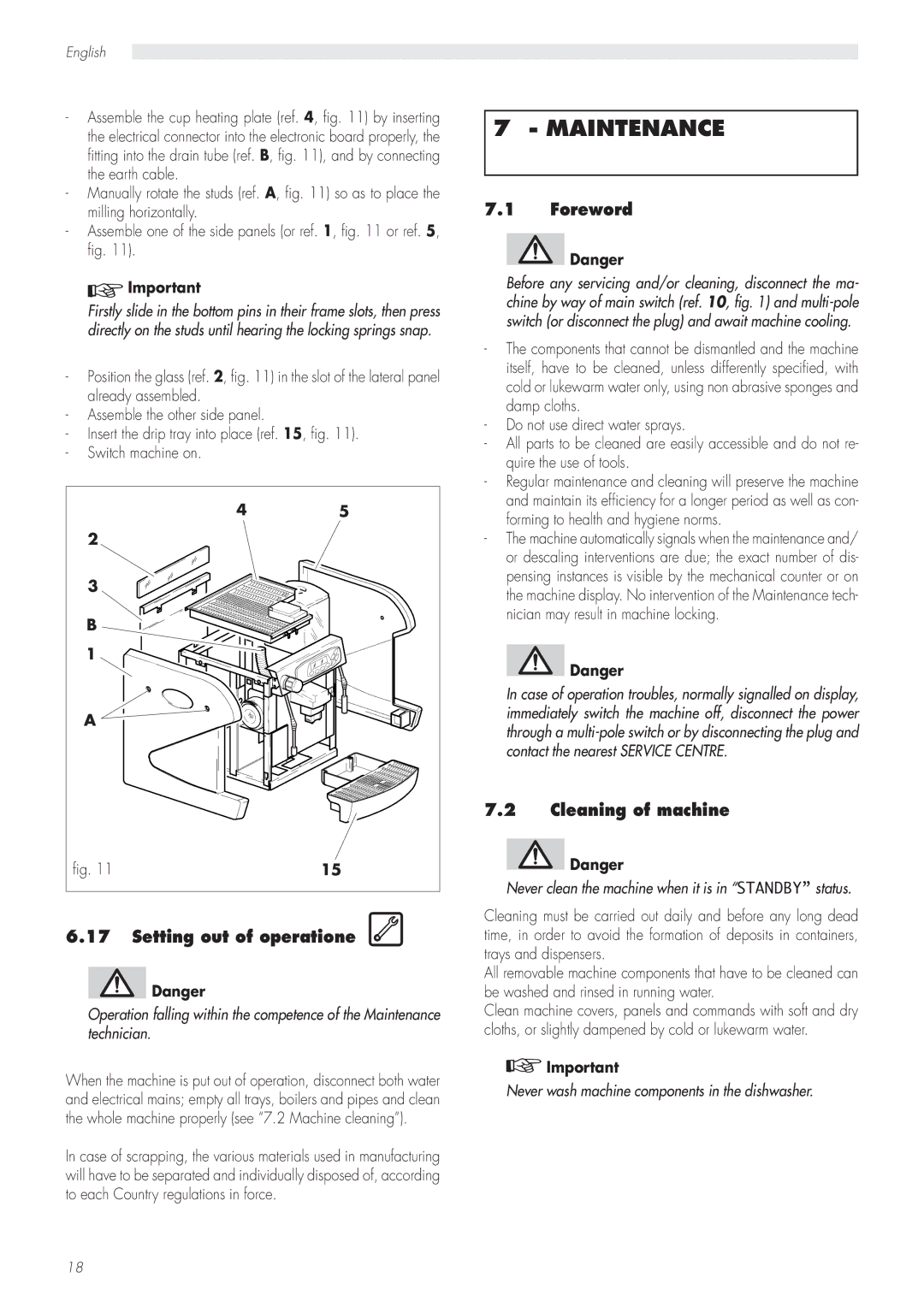

Cleaning and maintenance are made easy with the removable brew group and drip tray, allowing for quick access for rinsing and drying. The coffee maker also has a sleek, modern design that will complement any kitchen décor, with a compact build that does not occupy much counter space.

In summary, the Saeco Coffee Makers CAP001/A stands out with its ceramic grinder, one-touch brewing system, AquaClean filter, and automatic milk frother. Its thoughtful design and technology aspects cater to coffee lovers who seek convenience without compromising on quality. This coffee maker is an excellent addition to any household, promising a delightful brewing experience with each cup.