Cutting or extending the pipe

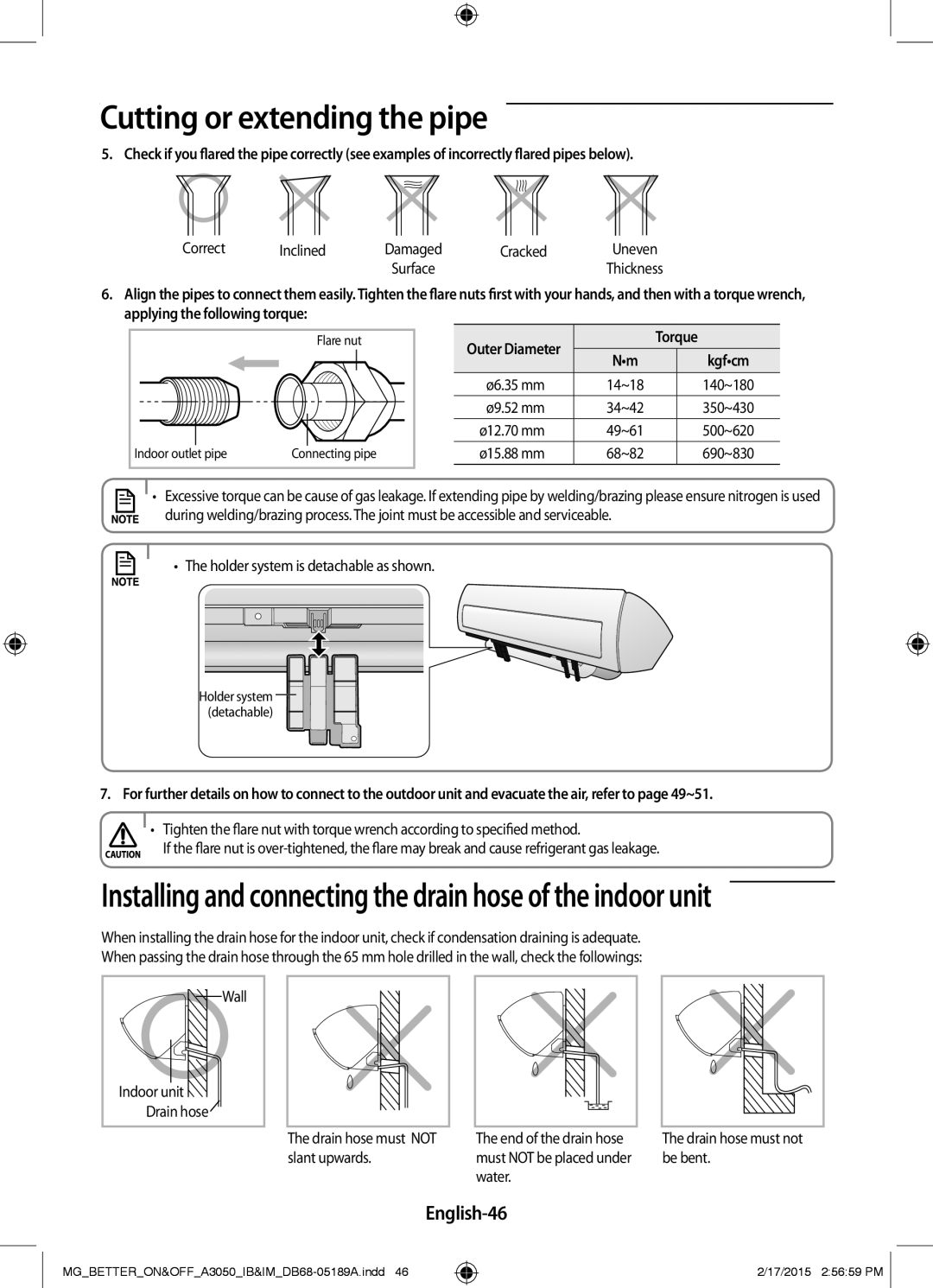

5. Check if you flared the pipe correctly (see examples of incorrectly flared pipes below).

Correct | Inclined | Damaged | Cracked | Uneven |

|

| Surface |

| Thickness |

6. Align the pipes to connect them easily. Tighten the flare nuts first with your hands, and then with a torque wrench, applying the following torque:

Flare nut

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor outlet |

| pipe |

|

|

|

| ||

| Connecting pipe | |||||||

Outer Diameter |

| Torque | |

N•m |

| kgf•cm | |

|

| ||

ø6.35 mm | 14~18 |

| 140~180 |

ø9.52 mm | 34~42 |

| 350~430 |

ø12.70 mm | 49~61 |

| 500~620 |

ø15.88 mm | 68~82 |

| 690~830 |

• Excessive torque can be cause of gas leakage. If extending pipe by welding/brazing please ensure nitrogen is used

during welding/brazing process. The joint must be accessible and serviceable.

• The holder system is detachable as shown..

Holder system (detachable)

7. For further details on how to connect to the outdoor unit and evacuate the air, refer to page 49~51.

• Tighten the flare nut with torque wrench according to specified method.

If the flare nut is

Installing and connecting the drain hose of the indoor unit

When installing the drain hose for the indoor unit, check if condensation draining is adequate. When passing the drain hose through the 65 mm hole drilled in the wall, check the followings:

![]() Wall

Wall

Indoor unit ![]()

![]()

Drain hose![]()

The drain hose must NOT slant upwards.

The end of the drain hose must NOT be placed under water.

The drain hose must not be bent.

English-46

2/17/2015 2:56:59 PM ![]()