Performing the gas leak tests

Make sure to check for gas leaks before completing the installation process (connecting the assembly pipe and hose between indoor unit and outdoor unit, insulating the cables, hose and pipe, and fixing the indoor unit to the installation plate).

![]()

![]()

![]() A C

A C ![]()

![]()

B

D

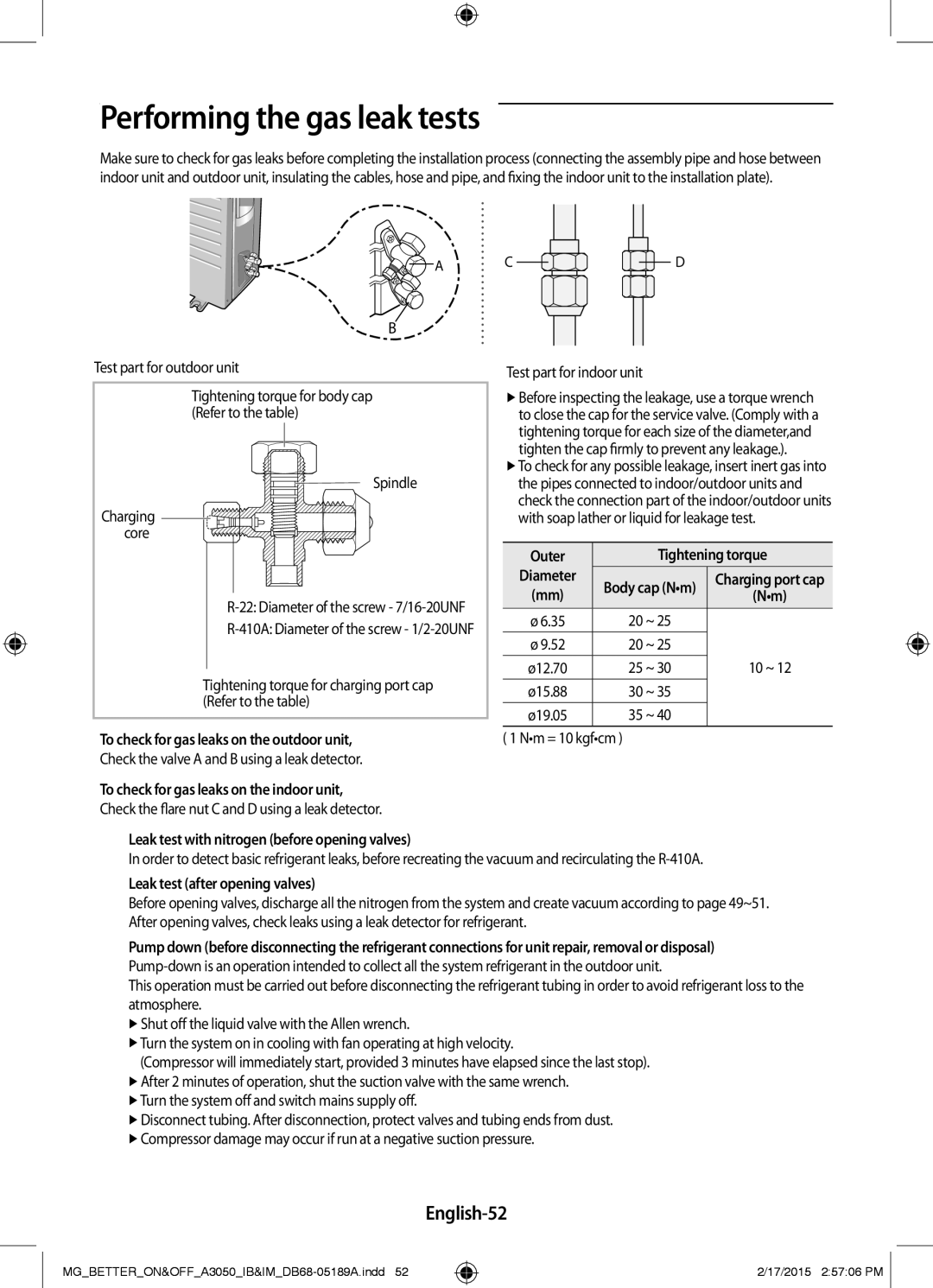

Test part for outdoor unit

Tightening torque for body cap (Refer to the table)

Spindle

Charging core

Tightening torque for charging port cap (Refer to the table)

Test part for indoor unit

Before inspecting the leakage, use a torque wrench to close the cap for the service valve. (Comply with a tightening torque for each size of the diameter,and tighten the cap firmly to prevent any leakage.).

To check for any possible leakage, insert inert gas into the pipes connected to indoor/outdoor units and check the connection part of the indoor/outdoor units with soap lather or liquid for leakage test.

Outer | Tightening torque | ||

Diameter | Body cap (N•m) | Charging port cap | |

(mm) | (N•m) | ||

| |||

ø 6.35 | 20 ~ 25 |

| |

ø 9.52 | 20 ~ 25 |

| |

ø12.70 | 25 ~ 30 | 10 ~ 12 | |

ø15.88 | 30 ~ 35 |

| |

ø19.05 | 35 ~ 40 |

| |

To check for gas leaks on the outdoor unit, | ( 1 N•m = 10 kgf•cm ) |

Check the valve A and B using a leak detector. |

|

To check for gas leaks on the indoor unit, |

|

Check the flare nut C and D using a leak detector. |

|

Leak test with nitrogen (before opening valves)

In order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the

Leak test (after opening valves)

Before opening valves, discharge all the nitrogen from the system and create vacuum according to page 49~51. After opening valves, check leaks using a leak detector for refrigerant.

Pump down (before disconnecting the refrigerant connections for unit repair, removal or disposal)

This operation must be carried out before disconnecting the refrigerant tubing in order to avoid refrigerant loss to the atmosphere.

Shut off the liquid valve with the Allen wrench.

Turn the system on in cooling with fan operating at high velocity.

(Compressor will immediately start, provided 3 minutes have elapsed since the last stop).

After 2 minutes of operation, shut the suction valve with the same wrench.

Turn the system off and switch mains supply off.

Disconnect tubing. After disconnection, protect valves and tubing ends from dust.

Compressor damage may occur if run at a negative suction pressure.

English-52

2/17/2015 2:57:06 PM ![]()