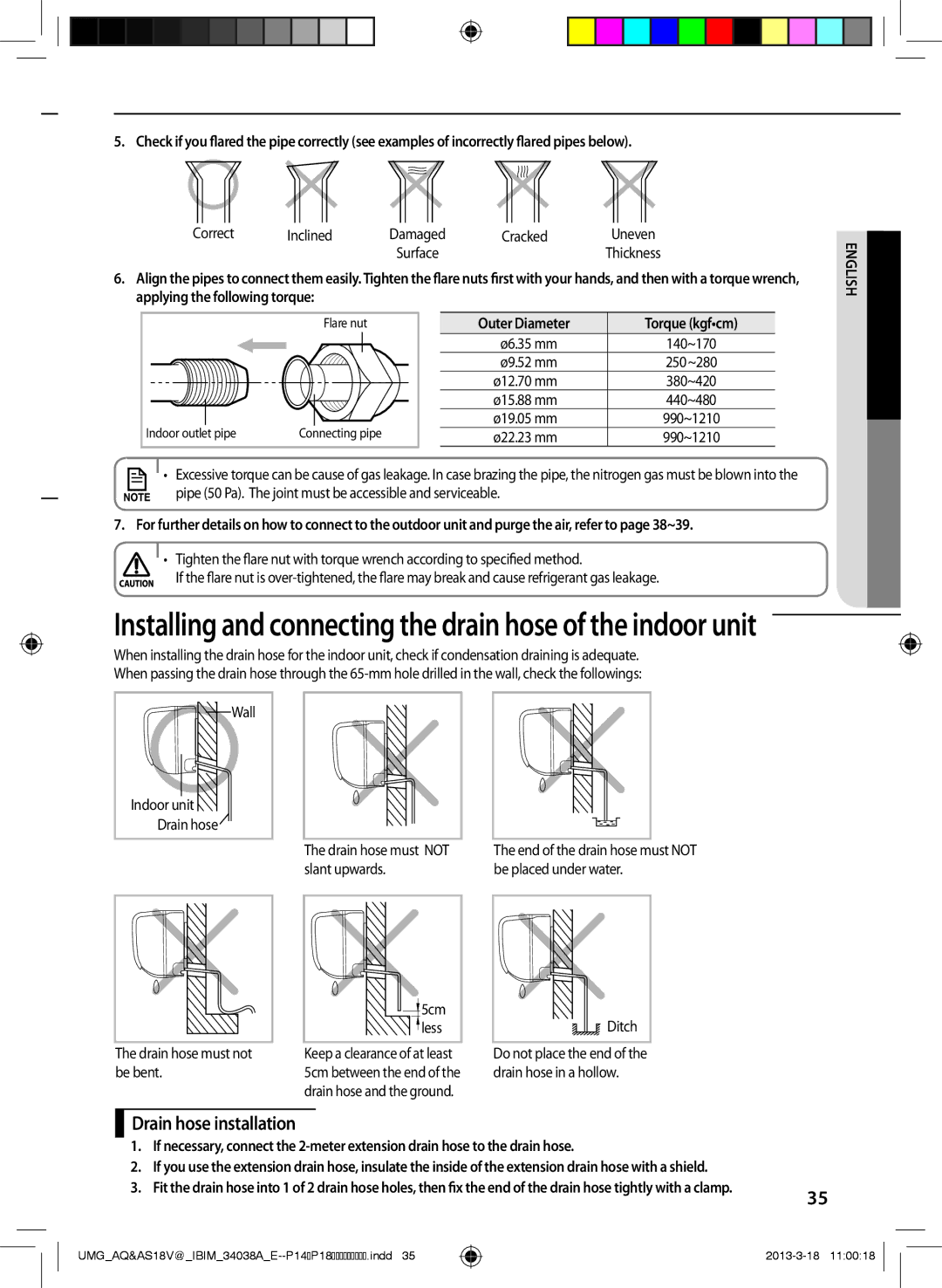

5. Check if you flared the pipe correctly (see examples of incorrectly flared pipes below).

Correct | Inclined | Damaged | Cracked | Uneven |

|

| Surface |

| Thickness |

6.Align the pipes to connect them easily. Tighten the flare nuts first with your hands, and then with a torque wrench, applying the following torque:

ENGLISH

Flare nut

|

|

|

|

|

|

|

|

|

|

|

Indoor outlet |

| pipe |

|

|

|

| ||||

| Connecting pipe | |||||||||

Outer Diameter | Torque (kgf•cm) |

ø6.35 mm | 140~170 |

ø9.52 mm | 250~280 |

ø12.70 mm | 380~420 |

ø15.88 mm | 440~480 |

ø19.05 mm | 990~1210 |

ø22.23 mm | 990~1210 |

• Excessive torque can be cause of gas leakage. In case brazing the pipe, the nitrogen gas must be blown into the

pipe (50 Pa). The joint must be accessible and serviceable.

7. For further details on how to connect to the outdoor unit and purge the air, refer to page 38~39.

• Tighten the flare nut with torque wrench according to specified method.

If the flare nut is

Installing and connecting the drain hose of the indoor unit

When installing the drain hose for the indoor unit, check if condensation draining is adequate.

When passing the drain hose through the

![]() Wall

Wall

Indoor unit ![]()

![]()

Drain hose![]()

The drain hose must NOT | The end of the drain hose must NOT |

slant upwards. | be placed under water. |

The drain hose must not be bent.

5cm |

less |

Keep a clearance of at least 5cm between the end of the drain hose and the ground.

![]() Ditch

Ditch

Do not place the end of the drain hose in a hollow.

Drain hose installation

1.If necessary, connect the

2.If you use the extension drain hose, insulate the inside of the extension drain hose with a shield.

3. Fit the drain hose into 1 of 2 drain hose holes, then fix the end of the drain hose tightly with a clamp. | 35 |

|

![]()

![]() P18���������

P18���������![]()

![]() .indd

.indd