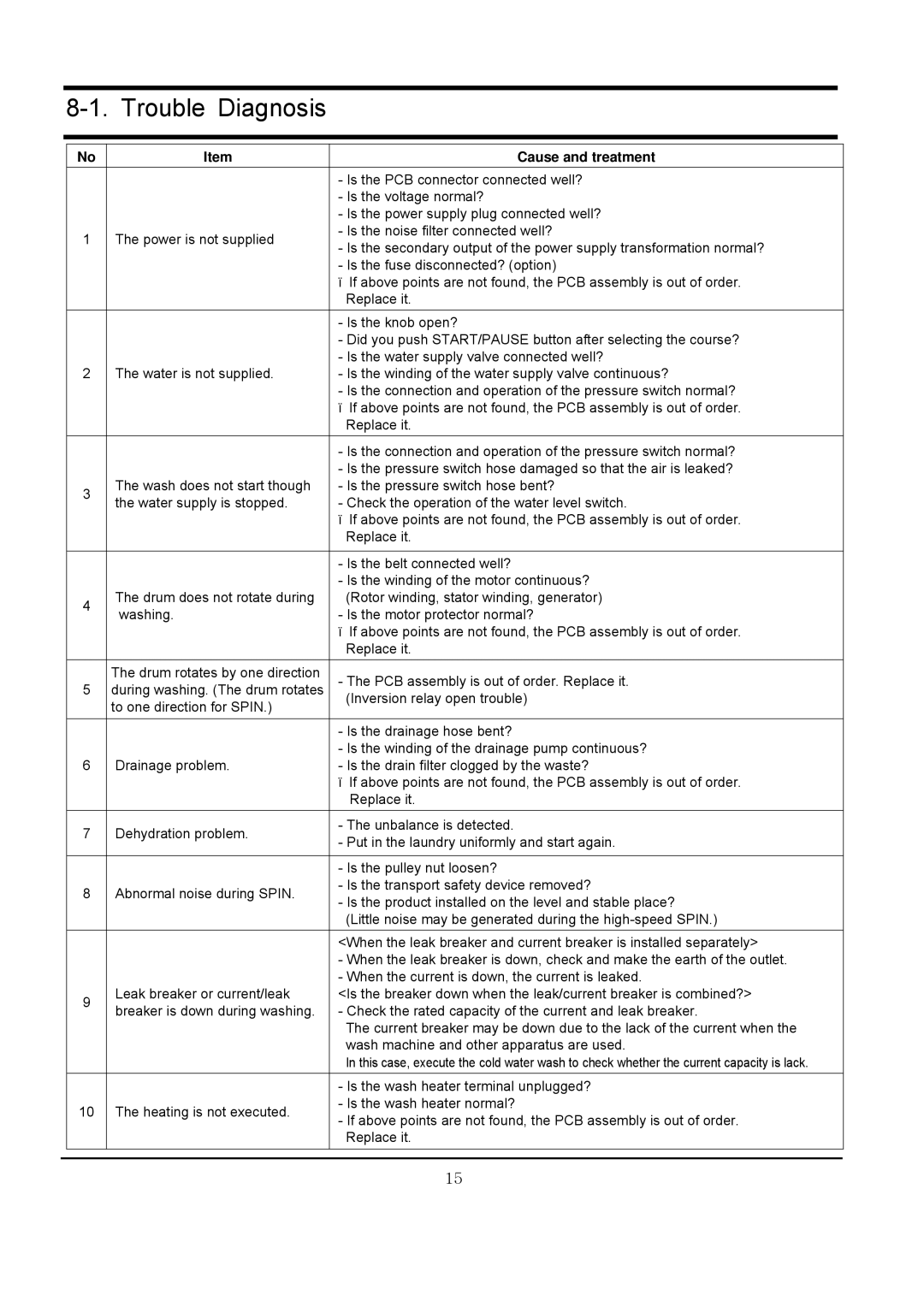

8-1. Trouble Diagnosis

| No | Item | Cause and treatment |

|

|

| - Is the PCB connector connected well? |

|

|

| - Is the voltage normal? |

|

|

| - Is the power supply plug connected well? |

| 1 | The power is not supplied | - Is the noise filter connected well? |

| - Is the secondary output of the power supply transformation normal? | ||

|

|

| |

|

|

| - Is the fuse disconnected? (option) |

|

|

| ï If above points are not found, the PCB assembly is out of order. |

|

|

| Replace it. |

|

|

| - Is the knob open? |

|

|

| - Did you push START/PAUSE button after selecting the course? |

| 2 | The water is not supplied. | - Is the water supply valve connected well? |

| - Is the winding of the water supply valve continuous? | ||

|

|

| - Is the connection and operation of the pressure switch normal? |

|

|

| ï If above points are not found, the PCB assembly is out of order. |

|

|

| Replace it. |

|

|

| - Is the connection and operation of the pressure switch normal? |

|

| The wash does not start though | - Is the pressure switch hose damaged so that the air is leaked? |

| 3 | - Is the pressure switch hose bent? | |

| the water supply is stopped. | - Check the operation of the water level switch. | |

|

| ||

|

|

| ï If above points are not found, the PCB assembly is out of order. |

|

|

| Replace it. |

|

|

|

|

|

|

| - Is the belt connected well? |

|

|

| - Is the winding of the motor continuous? |

| 4 | The drum does not rotate during | (Rotor winding, stator winding, generator) |

| washing. | - Is the motor protector normal? | |

|

| ||

|

|

| ï If above points are not found, the PCB assembly is out of order. |

|

|

| Replace it. |

| 5 | The drum rotates by one direction | - The PCB assembly is out of order. Replace it. |

| during washing. (The drum rotates | ||

|

| to one direction for SPIN.) | (Inversion relay open trouble) |

|

|

| |

|

|

|

|

|

|

| - Is the drainage hose bent? |

| 6 | Drainage problem. | - Is the winding of the drainage pump continuous? |

| - Is the drain filter clogged by the waste? | ||

|

|

| ï If above points are not found, the PCB assembly is out of order. |

|

|

| Replace it. |

| 7 | Dehydration problem. | - The unbalance is detected. |

| - Put in the laundry uniformly and start again. | ||

|

|

| |

|

|

|

|

|

|

| - Is the pulley nut loosen? |

| 8 | Abnormal noise during SPIN. | - Is the transport safety device removed? |

| - Is the product installed on the level and stable place? | ||

|

|

| |

|

|

| (Little noise may be generated during the |

|

|

| <When the leak breaker and current breaker is installed separately> |

|

|

| - When the leak breaker is down, check and make the earth of the outlet. |

|

| Leak breaker or current/leak | - When the current is down, the current is leaked. |

| 9 | <Is the breaker down when the leak/current breaker is combined?> | |

| breaker is down during washing. | - Check the rated capacity of the current and leak breaker. | |

|

| ||

|

|

| The current breaker may be down due to the lack of the current when the |

|

|

| wash machine and other apparatus are used. |

|

|

| In this case, execute the cold water wash to check whether the current capacity is lack. |

|

|

| - Is the wash heater terminal unplugged? |

| 10 | The heating is not executed. | - Is the wash heater normal? |

| - If above points are not found, the PCB assembly is out of order. | ||

|

|

| |

|

|

| Replace it. |

|

|

|

|

|

|

|

|

15