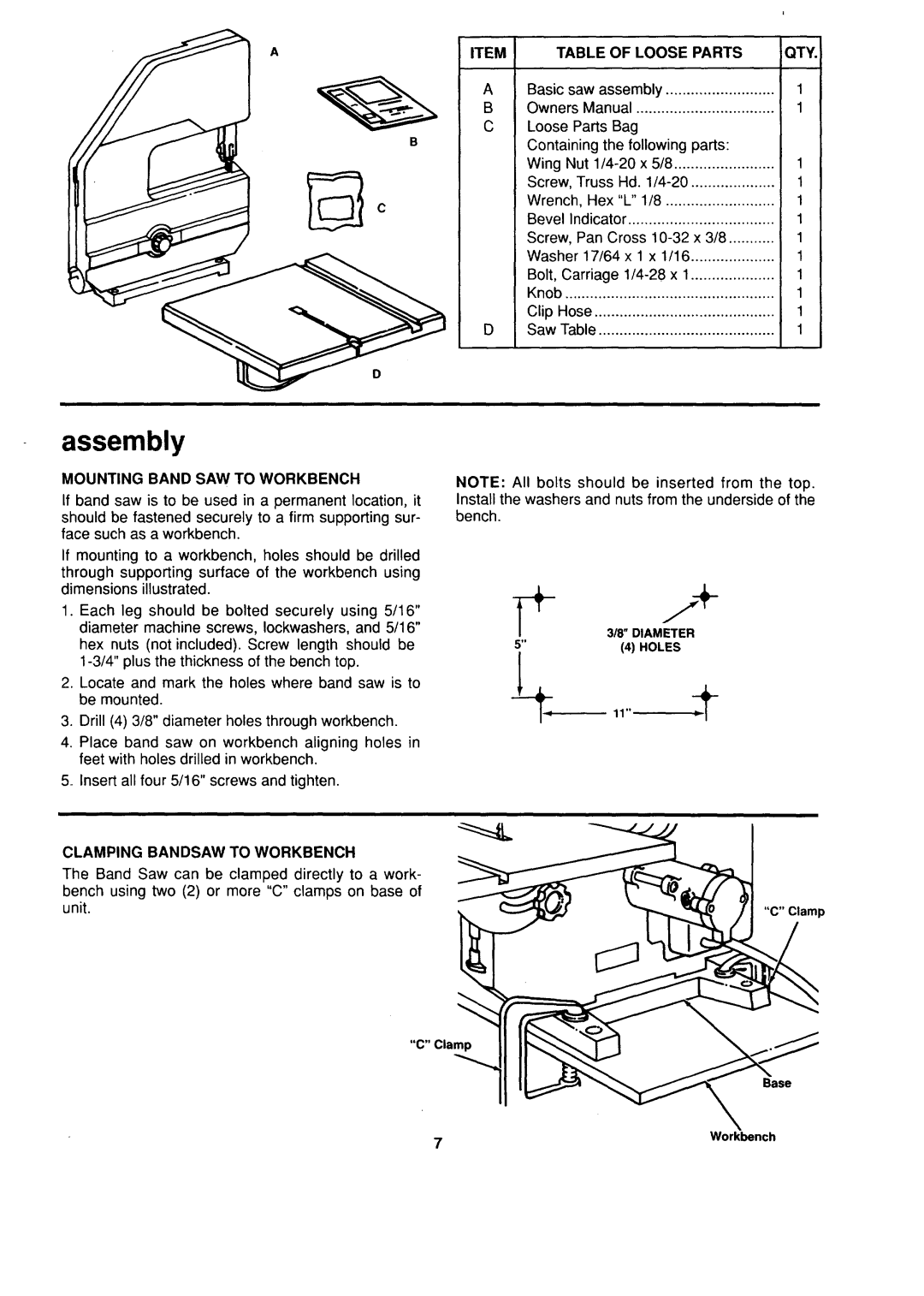

A | ITEM | TABLE OF LOOSE | PARTS | QTY. | |

| A | Basic saw assembly | 1 | ||

| B | Owners | Manual | 1 | |

| C | Loose Parts Bag |

|

| |

|

| Containing the following | parts: |

| |

|

| Wing Nut | 1 | ||

|

| Screw, Truss Hd. | .................... | 1 | |

|

| Wrench, Hex "L" 1/8 | 1 | ||

| c |

|

|

|

|

|

| Bevel Indicator | 1 | ||

|

| Screw, | Pan Cross | 1 | |

|

| Washer | 17/64 x 1 x 1/16 | .................... | 1 |

|

| Bolt, Carriage | .................... | 1 | |

|

| Knob |

| 1 | |

|

| Clip Hose | 1 | ||

| D | Saw Table | 1 | ||

| D |

|

|

|

|

assembly

MOUNTING BAND SAW TO WORKBENCH

If band saw is to be used in a permanent location, it

should be fastened securely to a firm supporting sur- face such as a workbench.

NOTE: All bolts should be inserted from the top. Install the washers and nuts from the underside of the bench.

If mounting to a workbench, holes should be drilled

through supporting surface of the workbench using dimensions illustrated.

1.Each leg should be bolted securely using 5/16" diameter machine screws, Iockwashers, and 5/16"

hex nuts (not included). Screw length should be

2.Locate and mark the holes where band saw is to be mounted.

3.Drill (4) 3/8" diameter holes through workbench.

4.Place band saw on workbench aligning holes in feet with holes drilled in workbench.

5.Insert all four 5/16" screws and tighten.

CLAMPING BANDSAW TO WORKBENCH

318" DIAMETE'_+R | |||

5" | (4) | HOLES | |

1 | |||

|

| ||

| 11" | ||

The Band Saw can be clamped directly to a work- bench using two (2) or more "C" clamps on base of unit.

"C" Clamp

"C" Clamp

Base