Safetyis a combination of operator common sense and

alertness at all times when the Jointer*Planer is being used.

WARNING: FOR YOUR OWN SAFETY, DO NOT AT- TEMPT TO OPERATE YOUR

IT IS COMPLETELY ASSEMBLED AND INSTALLED ACCORDING TO THE INSTRUCTIONS .., AND UNTIL YOU HAVE READ AND UNDERSTOOD THE FOLLOW-

ING.

|

|

|

|

|

| PAGE |

1. | GENERAL | SAFETY INSTRUCTIONS | FOR POWER | |||

| TOOLS | .................................. |

|

| 2 | |

2. | GETTING | TO KNOW YOUR | 12 | |||

3. | BASIC MACHINE | OPERATION | ............... | t8 | ||

4. | USE OF | BLOCKS | ......... | 19 | ||

5. | MAINTENANCE | ........................... |

| 21 | ||

6. | STABILITY | OF | MACHINE |

|

|

|

if there is any tendency for the

over or move during certain operations such as when

planing or jointing long heavy boards, the Jointer- Planer (stand) should be bofted to the floor.

7.LOCATION

The

This machine is intended for indoor use only. Provide adequate lighting.

8.KICKBACKS

Kickbacks can cause serious injury. A kickback occurs

when the operator looses control of the workpiece causing it to be kicked back toward him.

Kickbacks - and possible injury from them can usually be avoided by:

a.Hotdingthe workpiece firmly against tables and fence.

b.Not taking too deep a cut at one time. A deep cut requires more effort to feed the wood while pianing and can cause the wood to kickback. A cut between 1/32 and 1/16 of an inch deep will produce the best results.

c.Not jointing, planing, or beveling pieces of wood

smaller than recommended. (See section in this man-

ual,

d, Keeping blades sharp. Blades that are dull or nicked require more effort while planing and wilt tend to pound the wood rather than cut it, which can cause

the wood to kickback. A nicked blade will cut a rid-

ge in your wood and cause the wood to ride up on the outfeed table. Make sure the cutter blades are in-

stalled properly, and cutter blade wedge screws are tight.

9. PROTECTION: | EYES, HANDS, FACE, EARS, BODY |

If any part of yOur jointer is malfunctioning, has been damaged or broken . . . such as the motor switch, or other operating control, a safety device or the power

cord . . . cease operating immediately unlit the particular part is properly repaired or replaced.

b. Wear safety goggles that comply with ANSI Z87,1 and a face shield if operation is dusty. Wear ear plugs or muffs during extended periods of operation.

C. Do not plane, ioint, or bevel wood shorter than !2

in. Smaller pieces of wood can tip over on the tables, or into the cutterhead and be kicked back to- ward you,

Always use the hold down/push block when }ointing or beveling wood narrower than 3 in. but never ioint or bevel wood narrower than 3/4 in,, or less than 1/4 inch thick.

e. Always use the hold down/push blocks when planing wood thinner than 3 in, but never plane wood thinne_ than 1/2 in. under any circumstances.

f. Avoid awkward hand positions, where a sudden slip could cause a hand to move into the cutters.

Never turn your

h, Make sure the cutterhead revolves in the right direc- tion, (toward the infeed table).

i. KEEP CUTTER GUARD 1N PLACE AND OPERAT-

ING PROPERLY AT ALL TIMES. Regularly check

the tension of the cutter guard spring to assure

satisfactory operation. (See Getting To Know Your

Always feed the wood completely through the cutter head and past the cutter guard so that the guard re- turns to the rest position against the fence. When

using only one hold down/push block to feed the wood, do not place your other hand on the Jointer- Planer.

t0. Warped wood should be surface planed on the concave side for best results.

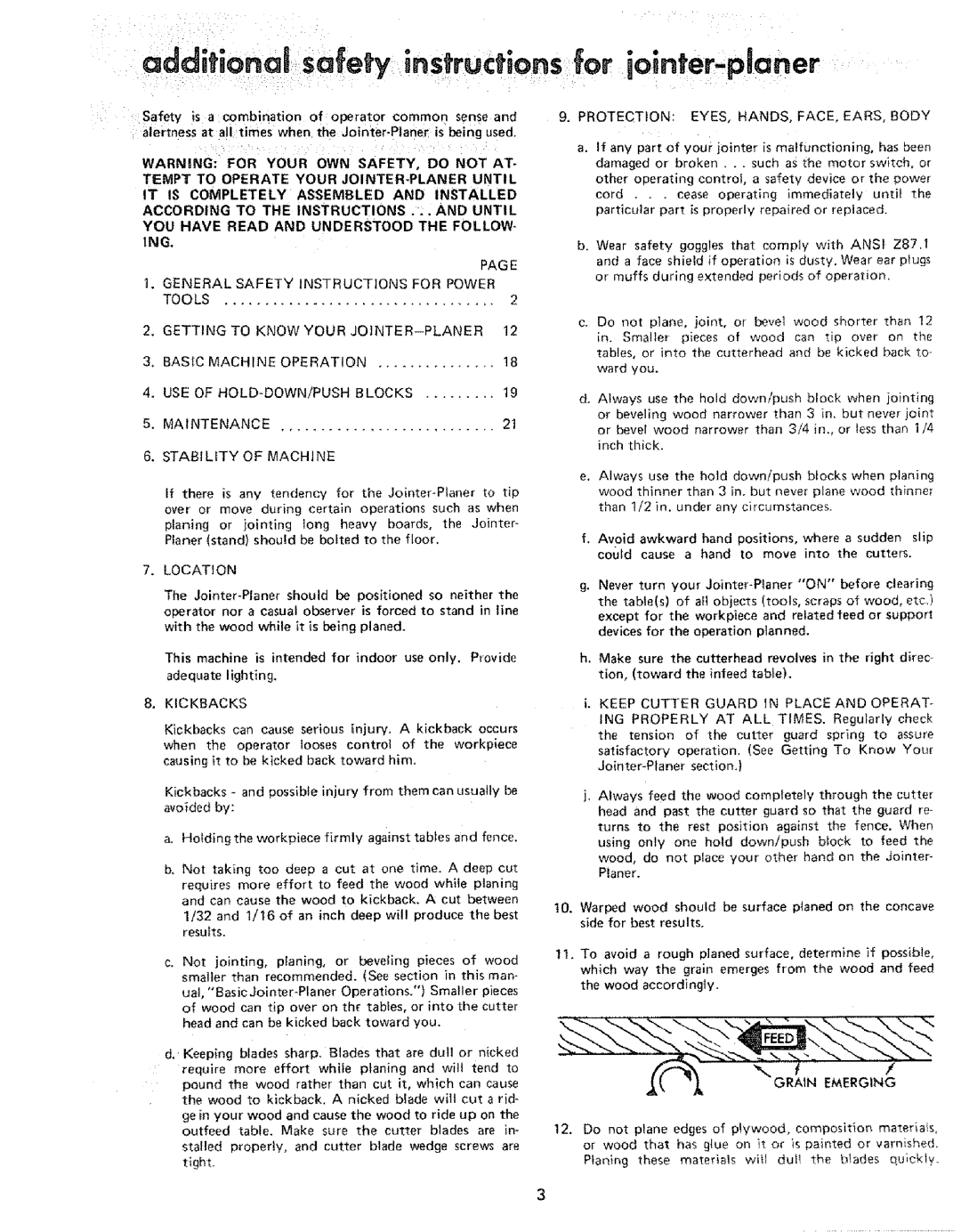

tl. To avoid a rough planed surface, determine if possible, which way the grain emerges from the wood and feed the wood accordingly.

!2. Do not plane edges of plywood, composition materials, or wood that has glue on it or is painted or varnished.

Planing these materials will dut_ the b_ades qu;ckl%