parts, find the following

18x 3/4 x2

7 Washers; 11/32 ID

7 Hex Jam NUts, 5/16-18

2 Cord Clips

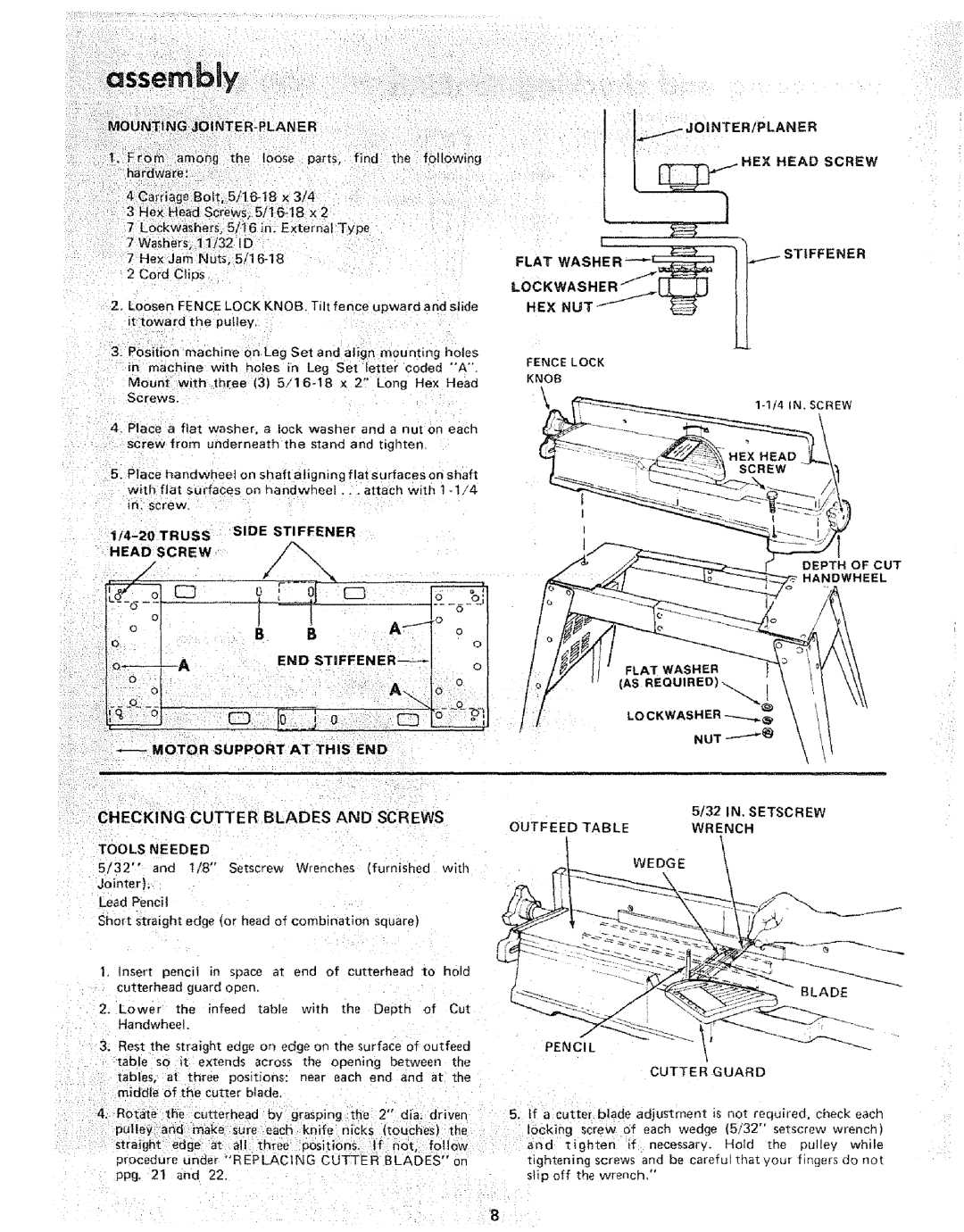

2.Loosen FENCE LOCK KNOB. Tilt fence upward and slide J_toward the pulley.

3.Position machine on Leg Set and align mounting holes

m machine with holes in Leg Set letter coded "'A".

Mount with three (3)

4.Place a flat washer, a lock washer and a nut on each

screw from underneath the stand and tighten.

5.Place handwhee] on shaft aligning flat surfaces on shaft

with flat surfaces on handwheel _.. attach with

114-20 TRUSS SIDE STIFFENER

HEAD SCREW

/

o o |

| !B | B | / ...._o | o | o |

°_A |

| END | STIFFENER |

| o | |

0 | o_ |

| : | : _ _ A | o 0 |

|

...... |

|

| _o_.D- | |||

MOTOR | SUPPORT AT | THIS | END |

|

| |

_ JONTERfPLANER

_HEX | HEAD SCREW |

FLATWASHER--- STFFENER

LOCK WAS H E

HEXNUT

FENCE LOCK

KNOB

I

I

I

I

DEPTH OF CUT

_DWHEEL

CHECKING-CUTTER: BLADES AND SCREWS

TOOLS NEEDED

5/32" and t/8" Setscrew Wrenches (furnished with Jointer).

Lead Pencil

Short straight edge (or head of combination square)

1.tnsert pencil in space at end of cutterhead to hold cutterhead guard open.

2.Lower the infeed table with the Depth of Cut Handwheel.

3.Rest the straight edge on edge on the surface of outfeed

table so it extends across the opening between the

tables, at three positions: near each end and at the middle of the cutter blade.

4.Rotate the cutterhead by grasping the 2" alia. driven pulley and make sure each knife nicks (touches) the

straight | edge | at a ! three | post on:s | tf not f0 | ow |

p ocedure | unde | REPLAC | NG CUTTER | BLADES | on |

ppg. 21 | and | 22. |

|

|

|

| 5/32 IN. SETSCREW |

OUTFEED TABLE | WRENCH |

WEDGE

BLADE

PENCI L

CUTTER GUARD

5.If a cutter blade adjustment _s not required, check each

locking screw of each wedge 15/32" setscrew wrench)

and tighten if necessary, Hold the pulley while

tightening screws and be careful that your f'ngers do not slip off the wrench,"