trouble" . i .: i " shooh• • n g

ETY, TURN SWITCH :ROM POWER SOURCE SHOOTING YOUR JOIN-

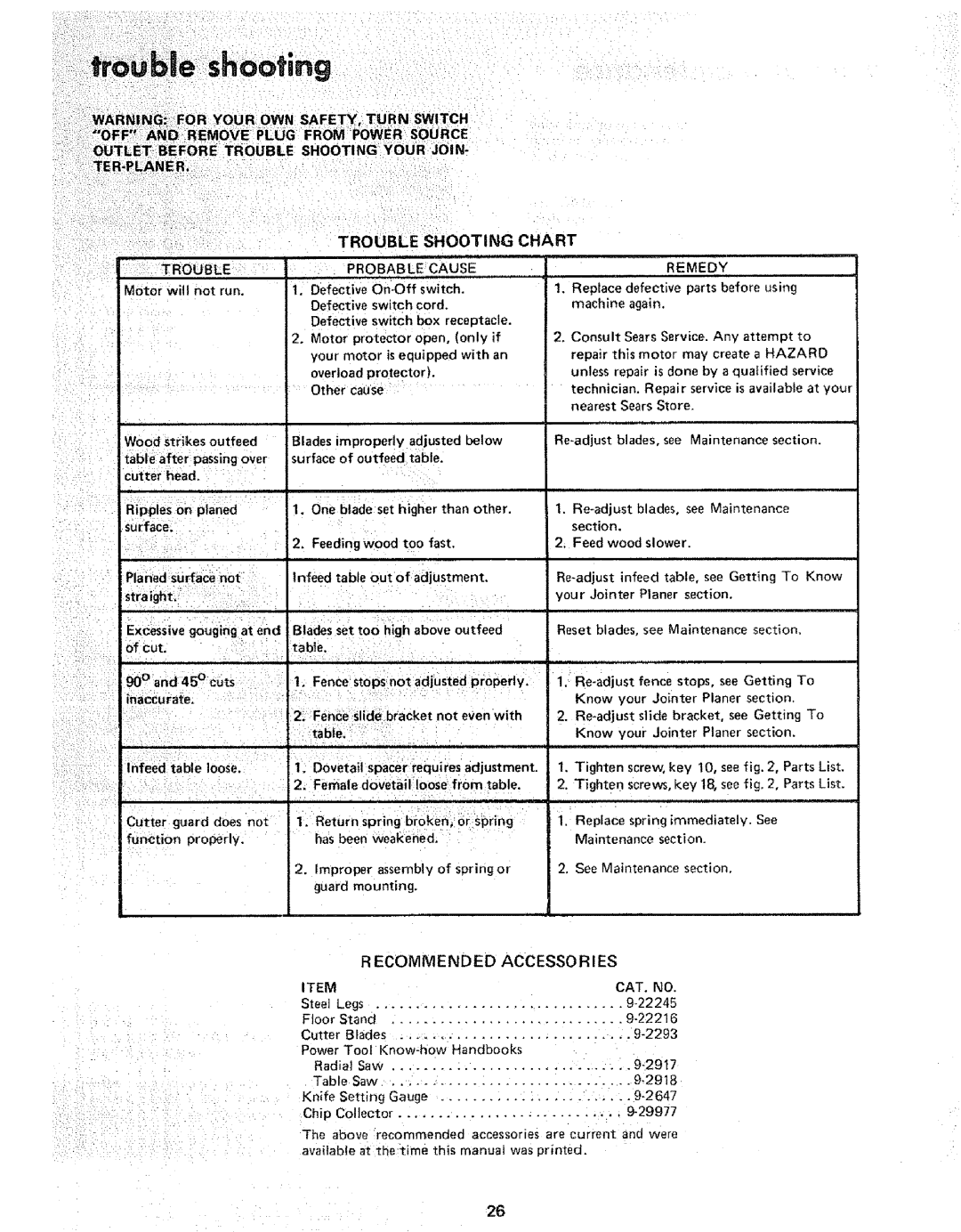

TROUBLE

Motor will not run.

'r ::

| TROUBLE | SHOOTING | CHART |

|

|

|

|

|

|

|

|

i | PROBABLE | CAus'E |

|

|

| REMEDY |

|

| |||

I. | 1. | Replace | defective | parts | before | using |

| ||||

| Defectiveswitchcord. |

| machine | again. |

|

|

|

| |||

| Defectiveswitchbox receptacle. |

|

|

|

|

|

|

|

| ||

2. | Motor protector open, (only if | 2. | Consult |

| Sears | Service. | Any attempt | to | |||

| your motor isequipped with an |

| repair | this motor | may | create a | HAZARD | ||||

| overload protector). |

| unless | repair | is done by a qualified service | ||||||

' | Other cause |

|

| technician. | Repair | service is available | at your | ||||

|

|

|

| nearest | Sears | Store, |

|

|

| ||

F

Wood | strikes | outfeed | Blades | improperly | adjusted | below | |

table after passing over | surface | of outfeed | table, |

| |||

|

|

|

| ||||

cutter | head. |

|

|

|

|

|

|

Ripples | on | planed | 1, | One | blade set higher than | other. | |

surface:. |

|

|

|

|

|

| |

|

|

| 2. | Feeding wood too fast. |

| ||

, ,, | ,=m_l,=,l |

1.

2.Feed wood slower.

i,

Planed | surface | not: |

| I nfeed table | out of | adjustment. |

|

| infeed table, | see Getting |

| To | Know | |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| your | Jointer | Planer section. |

|

|

|

|

| ||||||

Excessive | gouging | at end | Blades set too | high | above | outfeed |

| Reset | blades, | see | Maintenance | section. |

|

| ||||||||||||||

of Cut. |

|

| : | . table, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

90 ° and | 45 °cuts |

| !, | Fence | stops not | adjusted properly. | ! | !. | fence | stops | see | Getting |

| To |

| |||||||||||||

inaccurate. |

| ' |

| J |

|

|

|

|

|

|

|

| ' |

| Know | your | Jomter | Planer | sect=on. |

|

| |||||||

|

|

|

|

| 2_ Fence | slide | bracket | not | even | with |

| 2. | slide | bracket, | see Getting | To | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Know your Jointer Planer section. |

|

| ||||||||||

lnfeed | table | loose. |

| I. | Dovetail | spacer | requires | adjustment. |

| 1. | Tighten |

| screw, | key | t0, | see fig. | 2, | Parts | List. | |||||||||

|

|

|

|

| 2, | Female | dovetail | loose from | table. |

| 2. | Tighten |

| screws, | key | 18, see fig. | 2, | Parts | List. | |||||||||

|

|

|

|

| i | i |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cutter | guard | does | not | I 1. | Return | spring: | broke,, | Or sprin 9 | " | 1. | Replace |

| spring | immediately. | See |

|

|

| ||||||||||

function |

| properly, |

|

| has been | weakened. |

|

|

|

|

| Maintenance | section. |

|

|

|

|

|

| |||||||||

|

|

|

|

| 2. | Improper | assembly | of | spring | or |

| 2, | See Maintenance | section. |

|

|

|

|

| |||||||||

|

|

|

|

|

| guard | mounting. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| RECOMMENDED | ACCESSORIES |

| ||

ITEM |

|

|

|

| CAT. | NO. |

Steel | Legs | ............................... |

| |||

Floor | Stand | ............................. | ||||

Cutter |

| B_ades |

| |||

Power Tool |

| |||||

Radial | Saw | 9,2917 | ||||

Table | Saw | .............................. | ||||

Knife | Setting | Gauge | ||||

Chip | Collector | |||||

The | above | recommended | accessortes are current and | were | ||

available at the time this manual was printed.

26