OPERATION

OPERATION

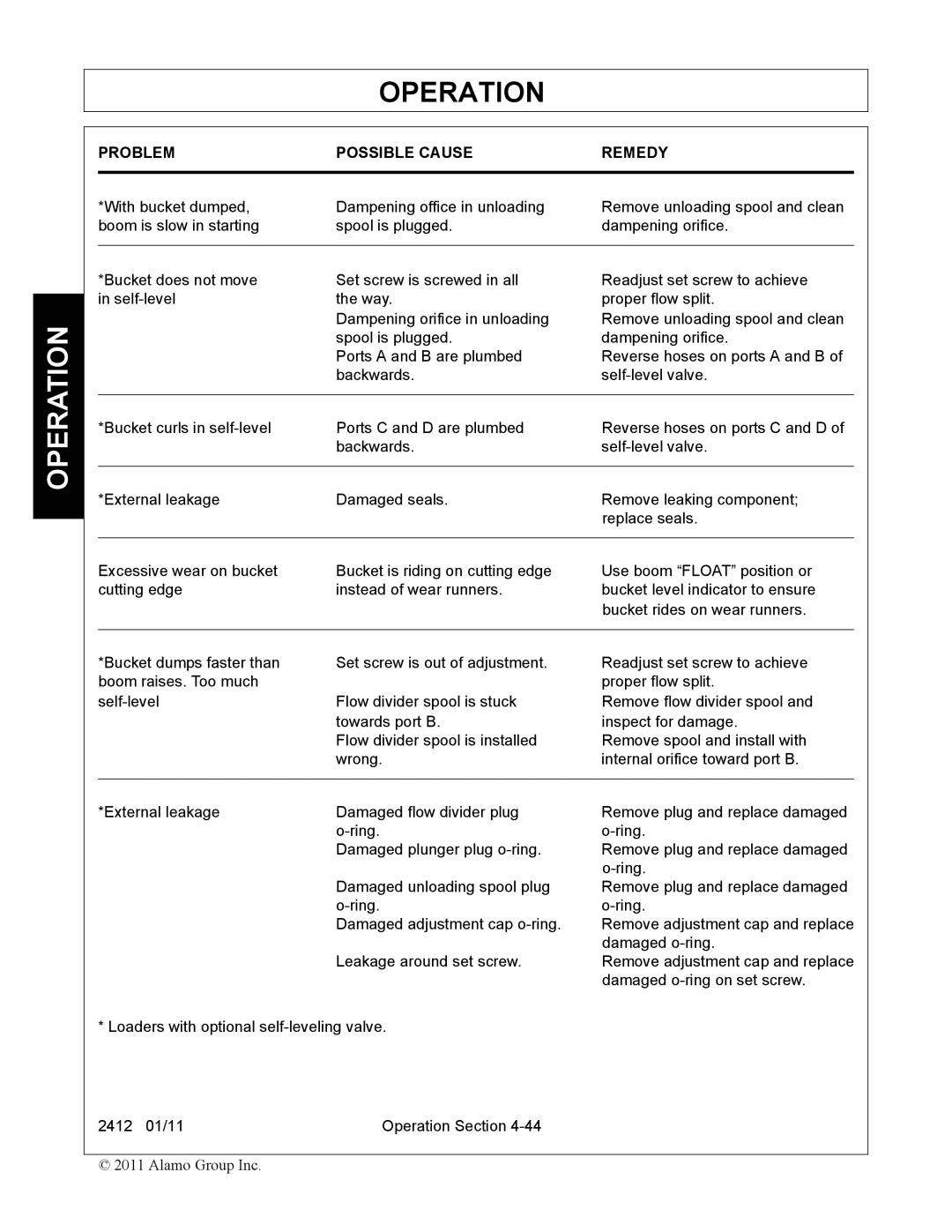

PROBLEM | POSSIBLE CAUSE | REMEDY |

|

|

|

*With bucket dumped, | Dampening office in unloading | Remove unloading spool and clean |

boom is slow in starting | spool is plugged. | dampening orifice. |

|

|

|

*Bucket does not move | Set screw is screwed in all | Readjust set screw to achieve |

in | the way. | proper flow split. |

| Dampening orifice in unloading | Remove unloading spool and clean |

| spool is plugged. | dampening orifice. |

| Ports A and B are plumbed | Reverse hoses on ports A and B of |

| backwards. | |

|

|

|

*Bucket curls in | Ports C and D are plumbed | Reverse hoses on ports C and D of |

| backwards. | |

|

|

|

*External leakage | Damaged seals. | Remove leaking component; |

|

| replace seals. |

|

|

|

Excessive wear on bucket | Bucket is riding on cutting edge | Use boom “FLOAT” position or |

cutting edge | instead of wear runners. | bucket level indicator to ensure |

|

| bucket rides on wear runners. |

|

|

|

*Bucket dumps faster than | Set screw is out of adjustment. | Readjust set screw to achieve |

boom raises. Too much |

| proper flow split. |

Flow divider spool is stuck | Remove flow divider spool and | |

| towards port B. | inspect for damage. |

| Flow divider spool is installed | Remove spool and install with |

| wrong. | internal orifice toward port B. |

|

|

|

*External leakage | Damaged flow divider plug | Remove plug and replace damaged |

| ||

| Damaged plunger plug | Remove plug and replace damaged |

|

| |

| Damaged unloading spool plug | Remove plug and replace damaged |

| ||

| Damaged adjustment cap | Remove adjustment cap and replace |

|

| damaged |

| Leakage around set screw. | Remove adjustment cap and replace |

|

| damaged |

* Loaders with optional

2412 01/11 | Operation Section |

© 2011 Alamo Group Inc.