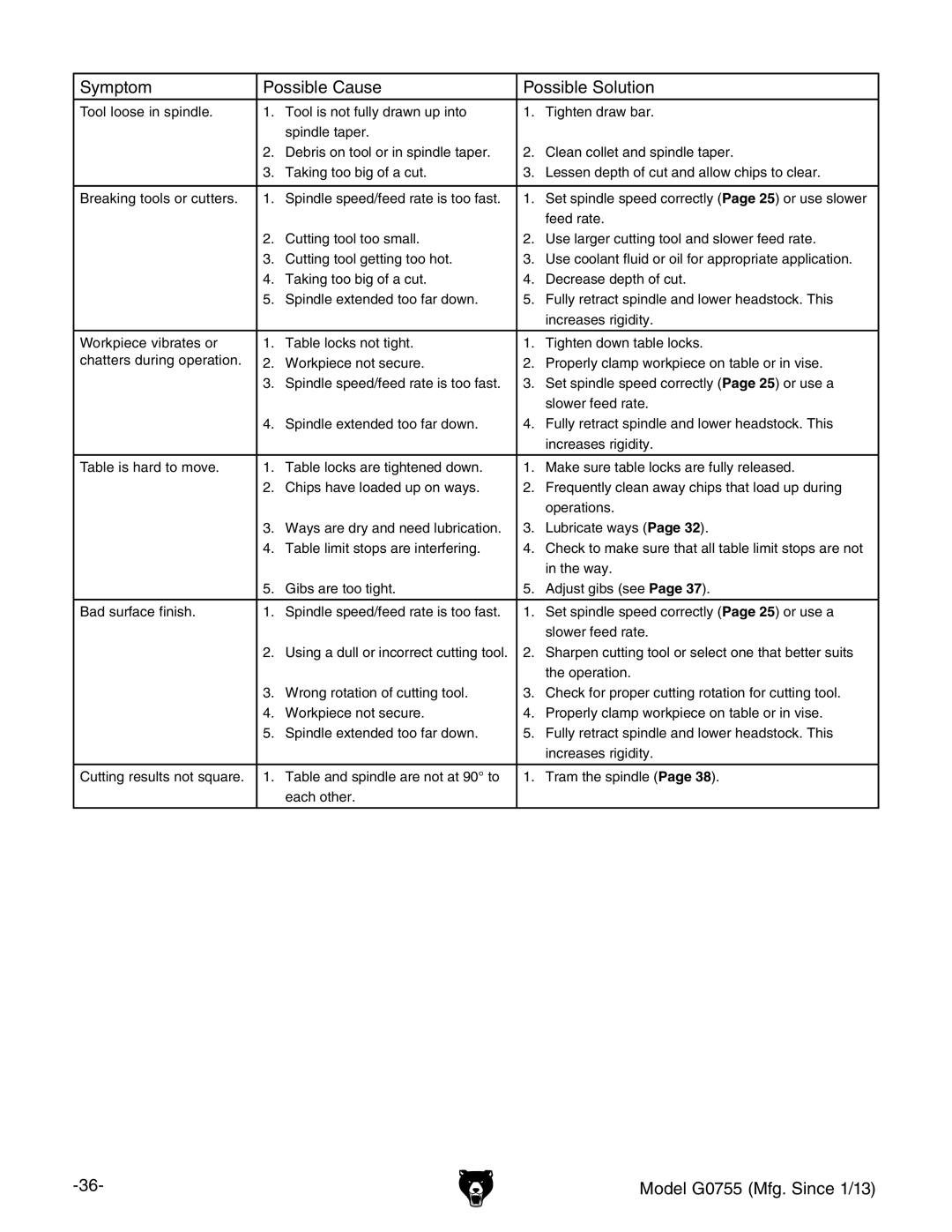

Symptom | Possible Cause | Possible Solution | ||

Tool loose in spindle. | 1. | tool is not fully drawn up into | 1. | tighten draw bar. |

|

| spindle taper. |

|

|

| 2. | debris on tool or in spindle taper. | 2. | Clean collet and spindle taper. |

| 3. | taking too big of a cut. | 3. | Lessen depth of cut and allow chips to clear. |

|

|

|

|

|

Breaking tools or cutters. | 1. | spindle speed/feed rate is too fast. | 1. | set spindle speed correctly (Page 25) or use slower |

|

|

|

| feed rate. |

| 2. | Cutting tool too small. | 2. | use larger cutting tool and slower feed rate. |

| 3. | Cutting tool getting too hot. | 3. | use coolant fluid or oil for appropriate application. |

| 4. | taking too big of a cut. | 4. | decrease depth of cut. |

| 5. | spindle extended too far down. | 5. | Fully retract spindle and lower headstock. This |

|

|

|

| increases rigidity. |

|

|

|

|

|

Workpiece vibrates or | 1. | table locks not tight. | 1. | tighten down table locks. |

chatters during operation. | 2. | Workpiece not secure. | 2. | properly clamp workpiece on table or in vise. |

| 3. | spindle speed/feed rate is too fast. | 3. | set spindle speed correctly (Page 25) or use a |

|

|

|

| slower feed rate. |

| 4. | spindle extended too far down. | 4. | Fully retract spindle and lower headstock. This |

|

|

|

| increases rigidity. |

|

|

|

|

|

Table is hard to move. | 1. | table locks are tightened down. | 1. | Make sure table locks are fully released. |

| 2. | Chips have loaded up on ways. | 2. | Frequently clean away chips that load up during |

|

|

|

| operations. |

| 3. | Ways are dry and need lubrication. | 3. | Lubricate ways (Page 32). |

| 4. | table limit stops are interfering. | 4. | Check to make sure that all table limit stops are not |

|

|

|

| in the way. |

| 5. | gibs are too tight. | 5. | Adjust gibs (see Page 37). |

|

|

|

|

|

Bad surface finish. | 1. | spindle speed/feed rate is too fast. | 1. | set spindle speed correctly (Page 25) or use a |

|

|

|

| slower feed rate. |

| 2. | using a dull or incorrect cutting tool. | 2. | sharpen cutting tool or select one that better suits |

|

|

|

| the operation. |

| 3. | Wrong rotation of cutting tool. | 3. | Check for proper cutting rotation for cutting tool. |

| 4. | Workpiece not secure. | 4. | properly clamp workpiece on table or in vise. |

| 5. | spindle extended too far down. | 5. | Fully retract spindle and lower headstock. This |

|

|

|

| increases rigidity. |

|

|

|

|

|

Cutting results not square. | 1. | table and spindle are not at 90° to | 1. | tram the spindle (Page 38). |

|

| each other. |

|

|

|

|

|

|

|

Model G0755 (Mfg. Since 1/13) |