Headstock Reservoir

Oil Type | Model T23962 or ISo 68 Equivalent | |

Oil Amount | 3⁜1⁄4 Qt. | |

Check/Add Frequency | 8 Hrs. of Operation | |

Change Frequency | Annually | |

The headstock has the proper amount of oil when the sight glass is halfway full (see Figure 42).

Sight

Glass

Figure 42. Headstock sight glass. |

|

Tool Needed | Qty |

Hex Wrench 8mm | 1 |

To change the headstock oil: |

|

1.run the spindle at 670 RPM for approximate- ly 10 minutes to warm the oil.

2.disCONNECT MACHINE FROM POWER!

3.Remove the fill plug (see Figure 43).

Fill

Plug

Figure 43. Headstock oil fill plug.

Model G0755 (Mfg. Since 1/13)

4.place a 1-gallon or larger drain pan on the table under the headstock.

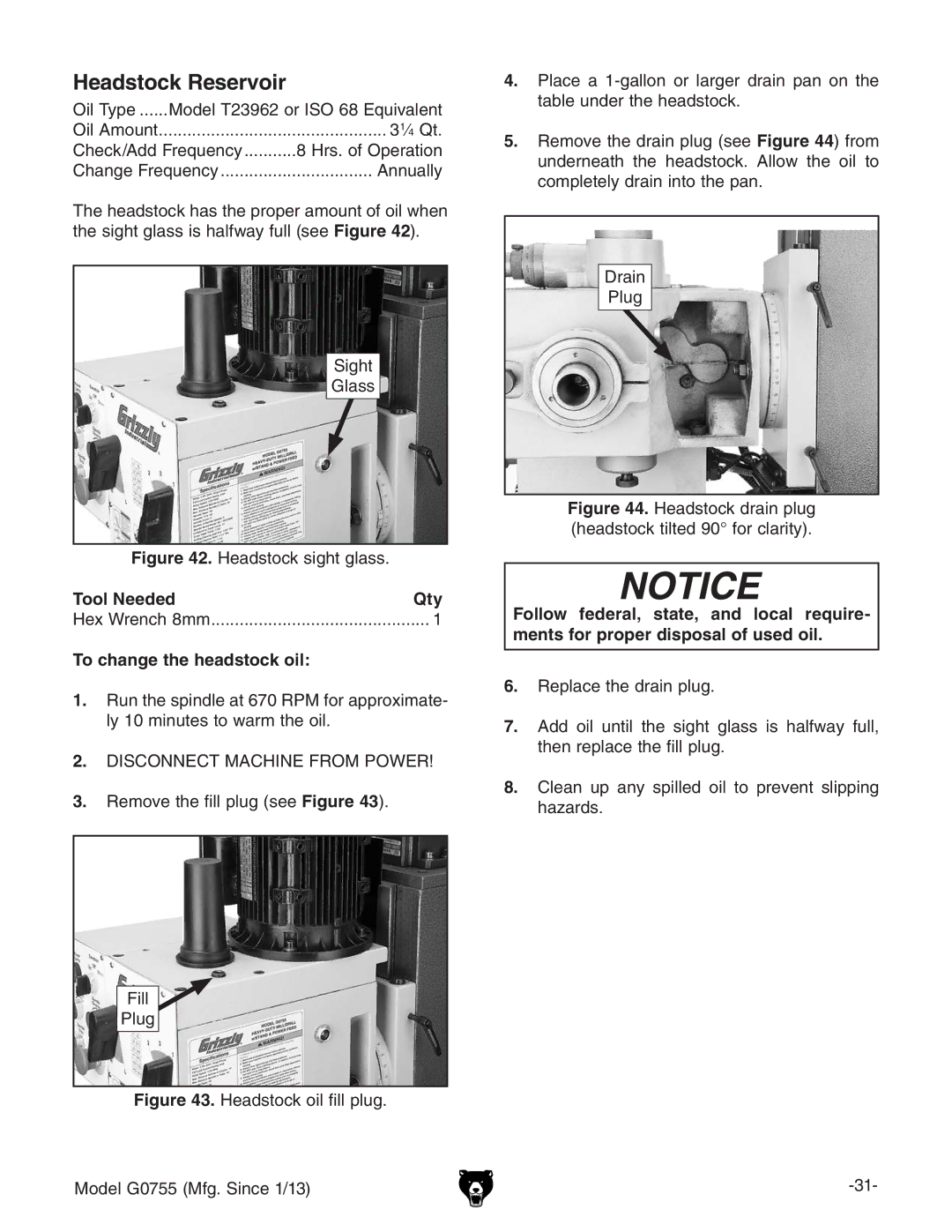

5.remove the drain plug (see Figure 44) from underneath the headstock. Allow the oil to completely drain into the pan.

Drain

Plug

Figure 44. Headstock drain plug (headstock tilted 90° for clarity).

Follow federal, state, and local require- ments for proper disposal of used oil.

6.Replace the drain plug.

7.Add oil until the sight glass is halfway full, then replace the fill plug.

8.Clean up any spilled oil to prevent slipping hazards.