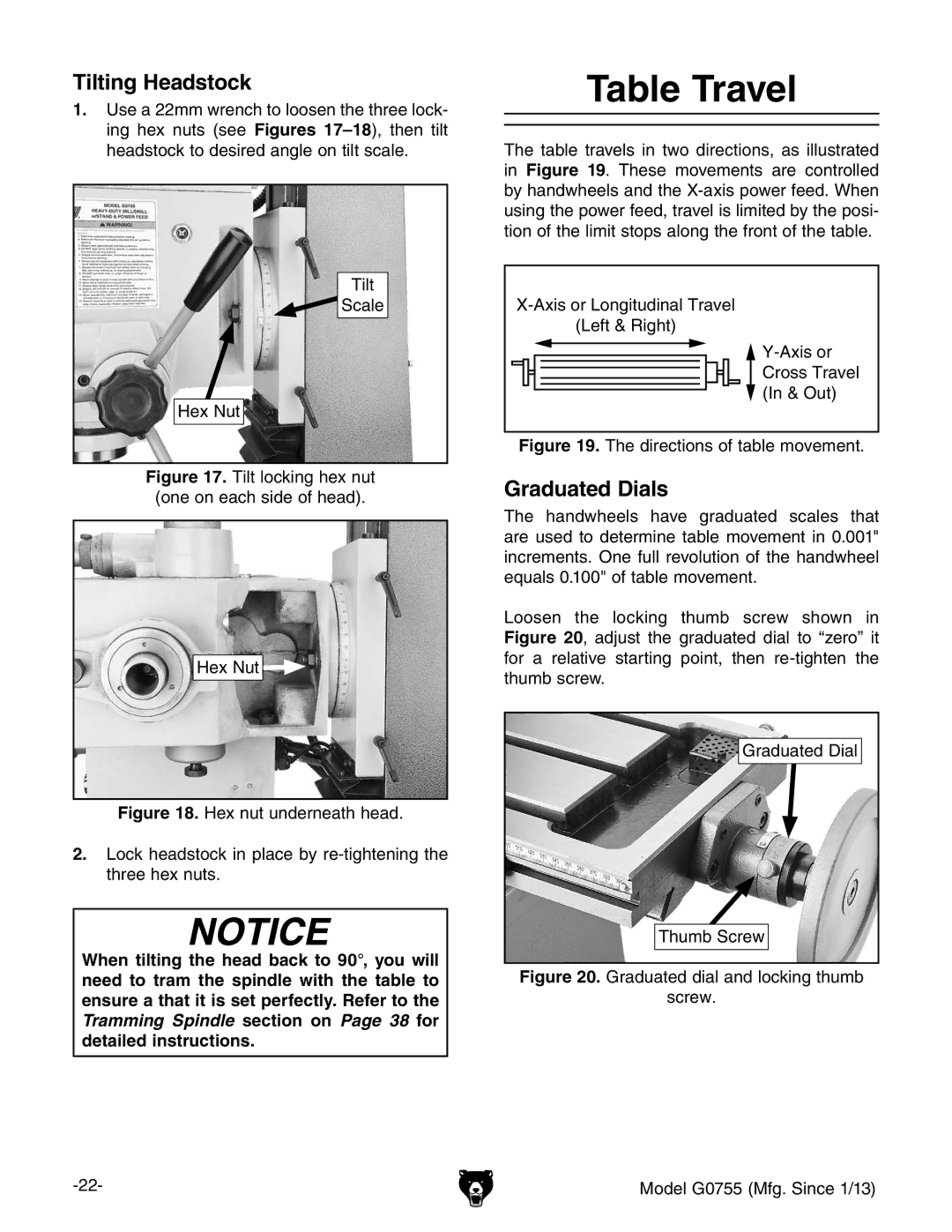

Tilting Headstock

1.Use a 22mm wrench to loosen the three lock- ing hex nuts (see Figures

Tilt

![]() Scale

Scale

Hex Nut

Figure 17. Tilt locking hex nut (one on each side of head).

Hex Nut

Figure 18. Hex nut underneath head.

2.Lock headstock in place by re-tightening the three hex nuts.

When tilting the head back to 90°, you will need to tram the spindle with the table to ensure a that it is set perfectly. Refer to the Tramming Spindle section on Page 38 for detailed instructions.

Table Travel

The table travels in two directions, as illustrated in Figure 19. These movements are controlled by handwheels and the

(Left & Right)

![]()

![]() Cross Travel

Cross Travel ![]()

![]() (In & Out)

(In & Out)

Figure 19. The directions of table movement.

Graduated Dials

The handwheels have graduated scales that are used to determine table movement in 0.001" increments. One full revolution of the handwheel equals 0.100" of table movement.

Loosen the locking thumb screw shown in Figure 20, adjust the graduated dial to “zero” it for a relative starting point, then

Graduated Dial

Thumb Screw