5.Place the parallel block directly under spindle and indicator across length of table, as illus- trated in Figure 57.

Note: If you must

Table (Top View)

Parallel Block

Indicator Spindle

Figure 57. Setup for the X-axis adjustment.

Note: Generally, the goal is to get the differ- ence of the indicator readings between ends of the parallel bar down to 0.0005". However, the acceptable variance will depend on the requirements for your operation.

6.rotate spindle by hand so that the indicator point rests on one end of parallel block, as illustrated in Figure 57, then zero dial.

7.rotate spindle so that the indicator point rests in the same manner on other end of block, then read dial.

—if indicator dial still reads zero or is within the acceptable variance, continue on with Step 8.

—If indicator dial has moved from zero beyond the acceptable variance, you will need to compensate for that amount by tilting head left or right. Repeat Steps 6–7 until you are satisfied with spindle axis alignment along table X-axis.

Tip: Keep one of the tilting hex nuts snug so that the head does not move loosely while you adjust it in small amounts.

8.

Model G0755 (Mfg. Since 1/13)

Replacing Power

Feed Carbon

Brushes

The

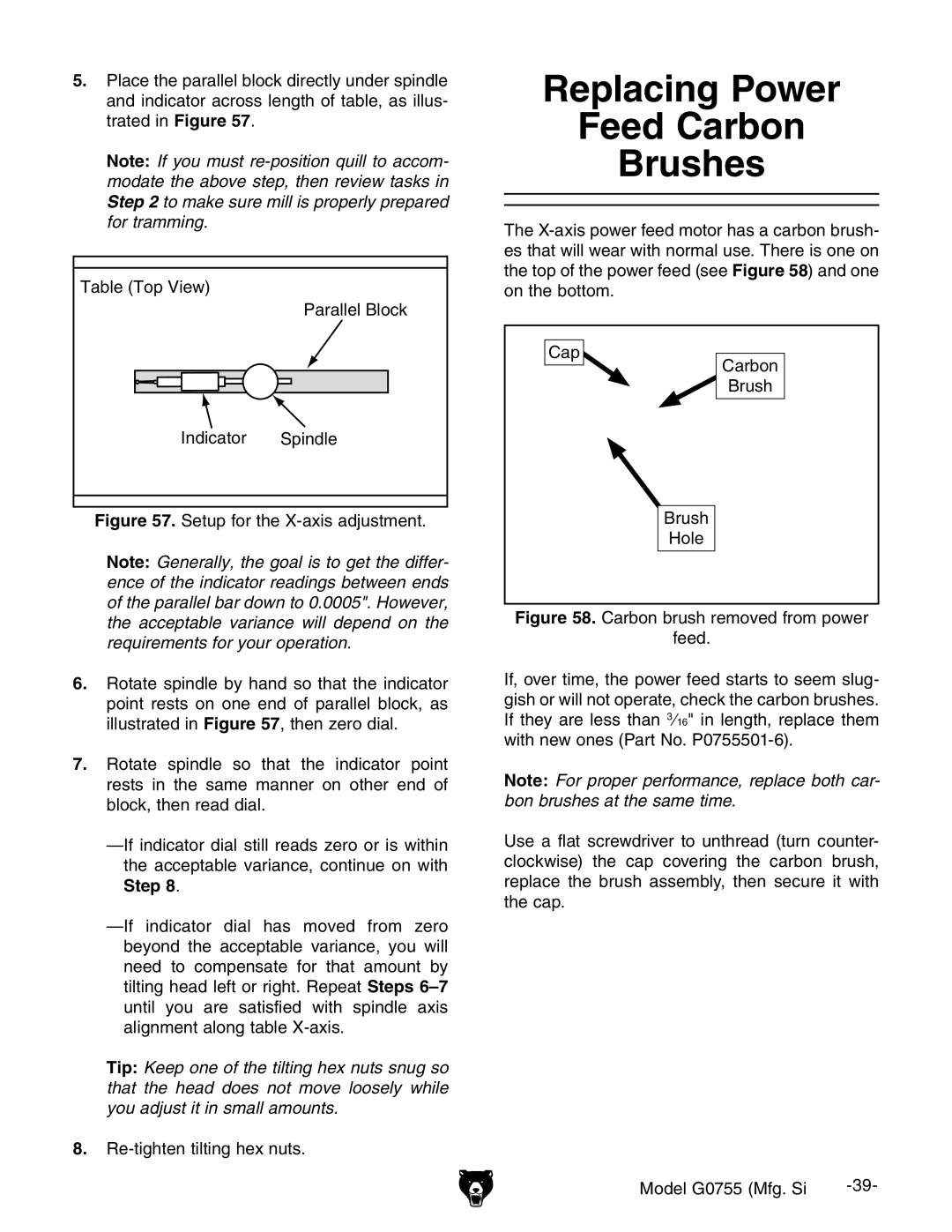

Cap

Carbon

![]() Brush

Brush

Brush

Hole

Figure 58. Carbon brush removed from power

feed.

If, over time, the power feed starts to seem slug- gish or will not operate, check the carbon brushes. If they are less than 3⁄16" in length, replace them with new ones (Part No. P0755501-6).

Note: For proper performance, replace both car- bon brushes at the same time.