Table Leadscrews

Oil Type.......Model T23962 or ISo 68 Equivalent

Oil Amount | Thin Coat |

Lubrication Frequency | 40 Hrs. of Operation |

Move the table as necessary to access the entire length of the X- and

Quill Rack & Pinion

Oil Type | NLGI#2 Grease or Equivalent | |

Oil Amount | Thin Coat | |

Lubrication Frequency | 90 Days of Operation | |

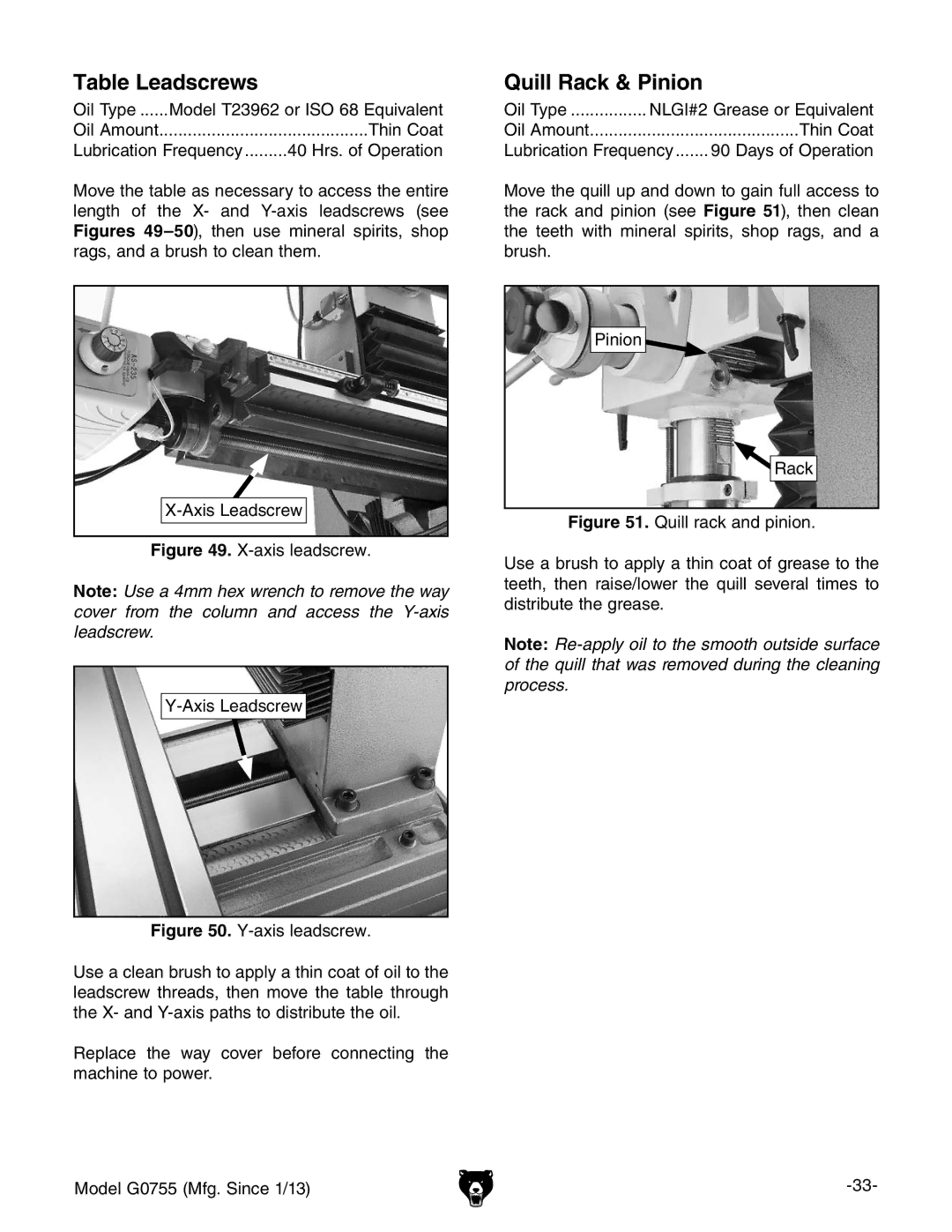

Move the quill up and down to gain full access to the rack and pinion (see Figure 51), then clean the teeth with mineral spirits, shop rags, and a brush.

Figure 49. X-axis leadscrew.

Note: Use a 4mm hex wrench to remove the way cover from the column and access the

Y-Axis Leadscrew

Figure 50. Y-axis leadscrew.

Use a clean brush to apply a thin coat of oil to the leadscrew threads, then move the table through the X- and Y-axis paths to distribute the oil.

Replace the way cover before connecting the machine to power.

Pinion

Rack

Rack

Figure 51. Quill rack and pinion.

Use a brush to apply a thin coat of grease to the teeth, then raise/lower the quill several times to distribute the grease.

Note:

Model G0755 (Mfg. Since 1/13) |