Ball Oilers

Oil Type | Model T23963 or ISo 32 Equivalent | |

Oil Amount | ||

Lubrication Frequency | 8 Hrs. of Operation | |

Proper lubrication of ball oilers (shown in Figures

Ball Oiler

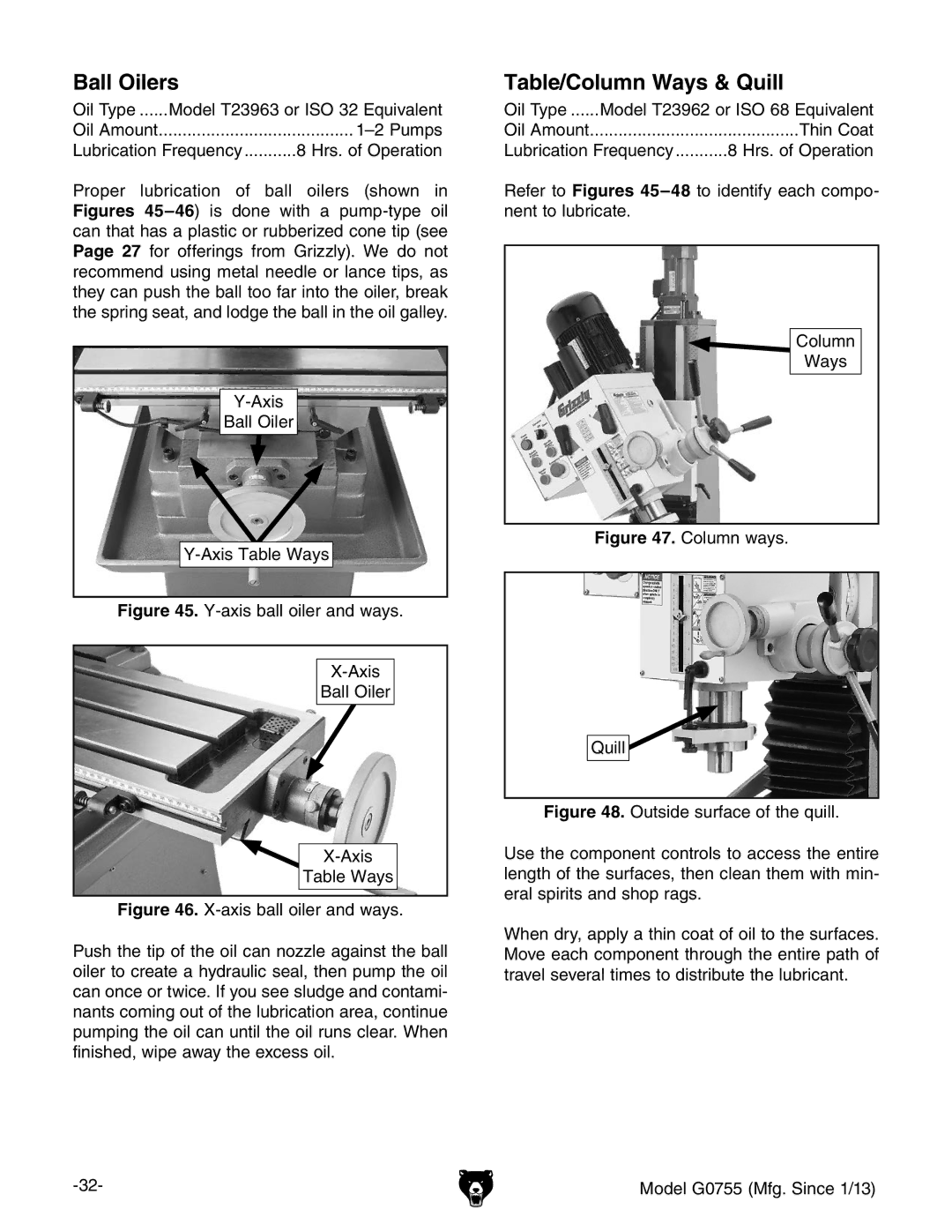

Figure 45. Y-axis ball oiler and ways.

Ball Oiler

Table Ways

Figure 46. X-axis ball oiler and ways.

Push the tip of the oil can nozzle against the ball oiler to create a hydraulic seal, then pump the oil can once or twice. If you see sludge and contami- nants coming out of the lubrication area, continue pumping the oil can until the oil runs clear. When finished, wipe away the excess oil.

Table/Column Ways & Quill

Oil Type.......Model T23962 or ISo 68 Equivalent

Oil Amount | Thin Coat |

Lubrication Frequency | 8 Hrs. of Operation |

Refer to Figures

Column

Ways

Figure 47. Column ways.

Quill

Figure 48. Outside surface of the quill.

Use the component controls to access the entire length of the surfaces, then clean them with min- eral spirits and shop rags.

When dry, apply a thin coat of oil to the surfaces. Move each component through the entire path of travel several times to distribute the lubricant.

Model G0755 (Mfg. Since 1/13) |