MAINTENANCE

MAINTENANCE

BLADE CARRIER INSTALLATION

Clean the splines on both the blade carrier and output shaft. Position carrier on the gear box output shaft and install flat washer and 1" hex nut. Tighten nut holding blade carrier to minimum 600 ft. pounds, strike the carrier on the hub several times with a heavy hammer to seat the hub. Use a suitable spacer over the nut to prevent damage to the nut and threads. Retighten the nut to 600 ft. pounds. Install and spread cotter pin.

NOTE: After a few hours of operation always recheck blade carrier retaining nut torque.

Operating the mower with a loose blade pan or holder can damage the taper connection on the gearbox output shaft. To ensure proper seating between the blade holder and output shaft check and tighten the retaining nut after the first day of operation. Recheck the blade carrier attachment each morning before operating. Grasp the carrier firmly with both hands and try to push and pull the carrier with one hand while pulling and pushing with the other hand to try to rock or oscillate the blade carrier. If the carrier is loose retighten the retaining nut before operating the mower.

Avoid personal injury. Do not work under cutter without support blocks to keep frame from falling.

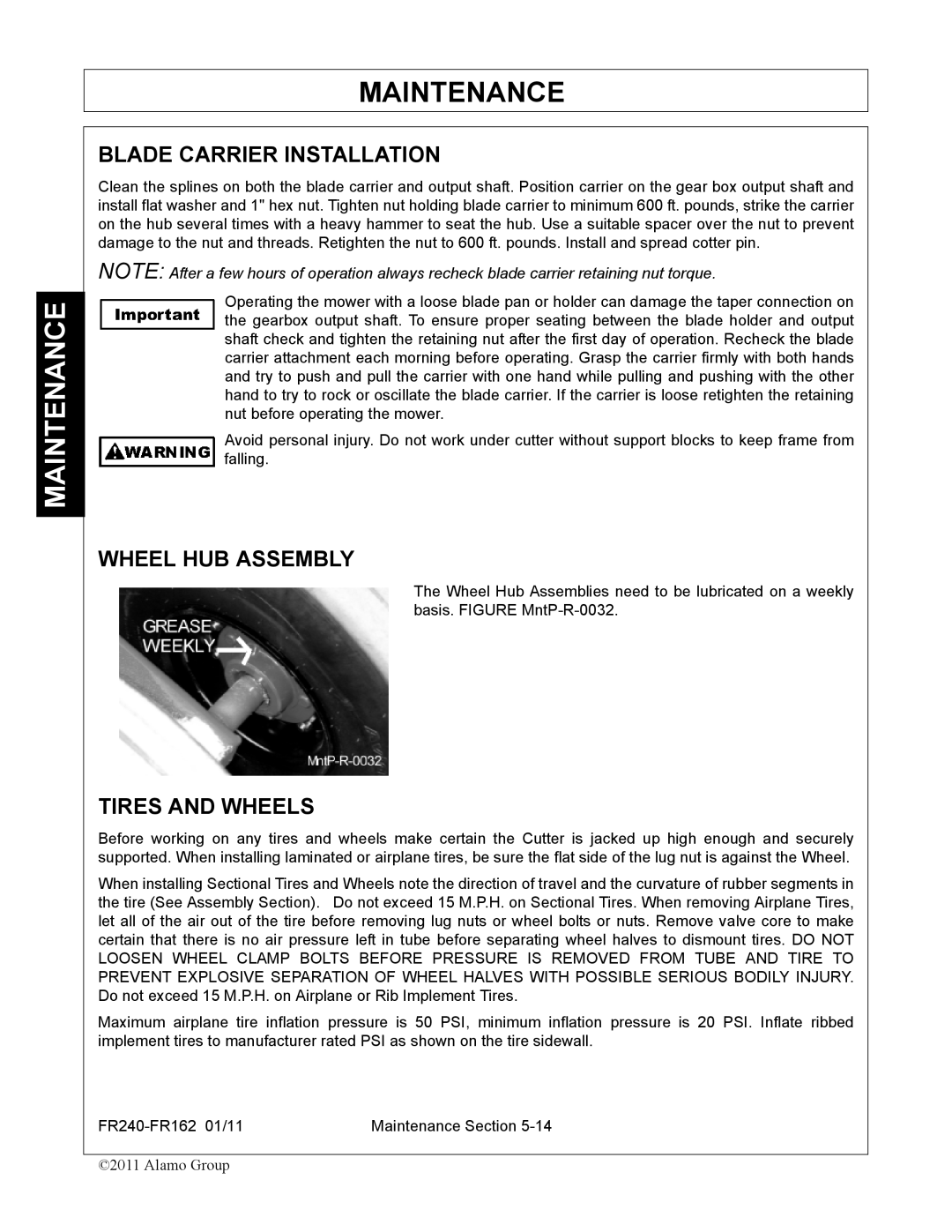

WHEEL HUB ASSEMBLY

The Wheel Hub Assemblies need to be lubricated on a weekly basis. FIGURE

TIRES AND WHEELS

Before working on any tires and wheels make certain the Cutter is jacked up high enough and securely supported. When installing laminated or airplane tires, be sure the flat side of the lug nut is against the Wheel.

When installing Sectional Tires and Wheels note the direction of travel and the curvature of rubber segments in the tire (See Assembly Section). Do not exceed 15 M.P.H. on Sectional Tires. When removing Airplane Tires, let all of the air out of the tire before removing lug nuts or wheel bolts or nuts. Remove valve core to make certain that there is no air pressure left in tube before separating wheel halves to dismount tires. DO NOT LOOSEN WHEEL CLAMP BOLTS BEFORE PRESSURE IS REMOVED FROM TUBE AND TIRE TO PREVENT EXPLOSIVE SEPARATION OF WHEEL HALVES WITH POSSIBLE SERIOUS BODILY INJURY. Do not exceed 15 M.P.H. on Airplane or Rib Implement Tires.

Maximum airplane tire inflation pressure is 50 PSI, minimum inflation pressure is 20 PSI. Inflate ribbed implement tires to manufacturer rated PSI as shown on the tire sidewall.

Maintenance Section |

©2011 Alamo Group