© Siemens AG 2011

Performance monitoring of turbo compressors with the block CompMon:

Depending on the type of medium, the aerodynamic perfor- mance of a turbo compressor can be impaired by fouling, caking, or abrasion. The location of the operating point can also be affected by variances in the state of the medium being pumped in depending on temperature, pressure and compo- sition or by changes to the flow resistance on the load side. The block CompMon calculates performance characteristics (e.g. conveyance or efficiency) and issues a warning if the cor- responding values indicate damage to the compressor, caking by pollutants on the runner or erosion of the blades from the fluid.

Standard diagnostics functions

In order to obtain information on the diagnostics status of in- dividual plant areas or components, maintenance engineers can change from the overview display to the respective diag- nostics display of the subordinate hardware level. If a fault is signaled in the overview display, the "loop in alarm" function permits rapid switching to the diagnostics faceplate of the as- sociated component. The information is filtered according to the area of responsibility of the user.

The following information can be offered:

•Display of diagnostics status determined by the system

•Information on the component, such as process tag name, manufacturer or serial number

•Display of diagnostics messages of a component

•Visualization of type and current state of initiated mainte- nance measure

Design of a Maintenance Station

The SIMATIC PCS 7 Maintenance Station is of modular design. In small plants it is possible to install the operator station and the Maintenance Station on the same PC. Just like the opera- tor system, the Maintenance Station can be expanded into a client/server application with

The SIMATIC PCS 7 Maintenance Station is based on standard SIMATIC products:

•SIMATIC PCS 7 ES / OS

for configuration and HMI functions

•SIMATIC PDM

for connecting the field devices and

•SIMATIC SNMP OPC Server

for interfacing network components

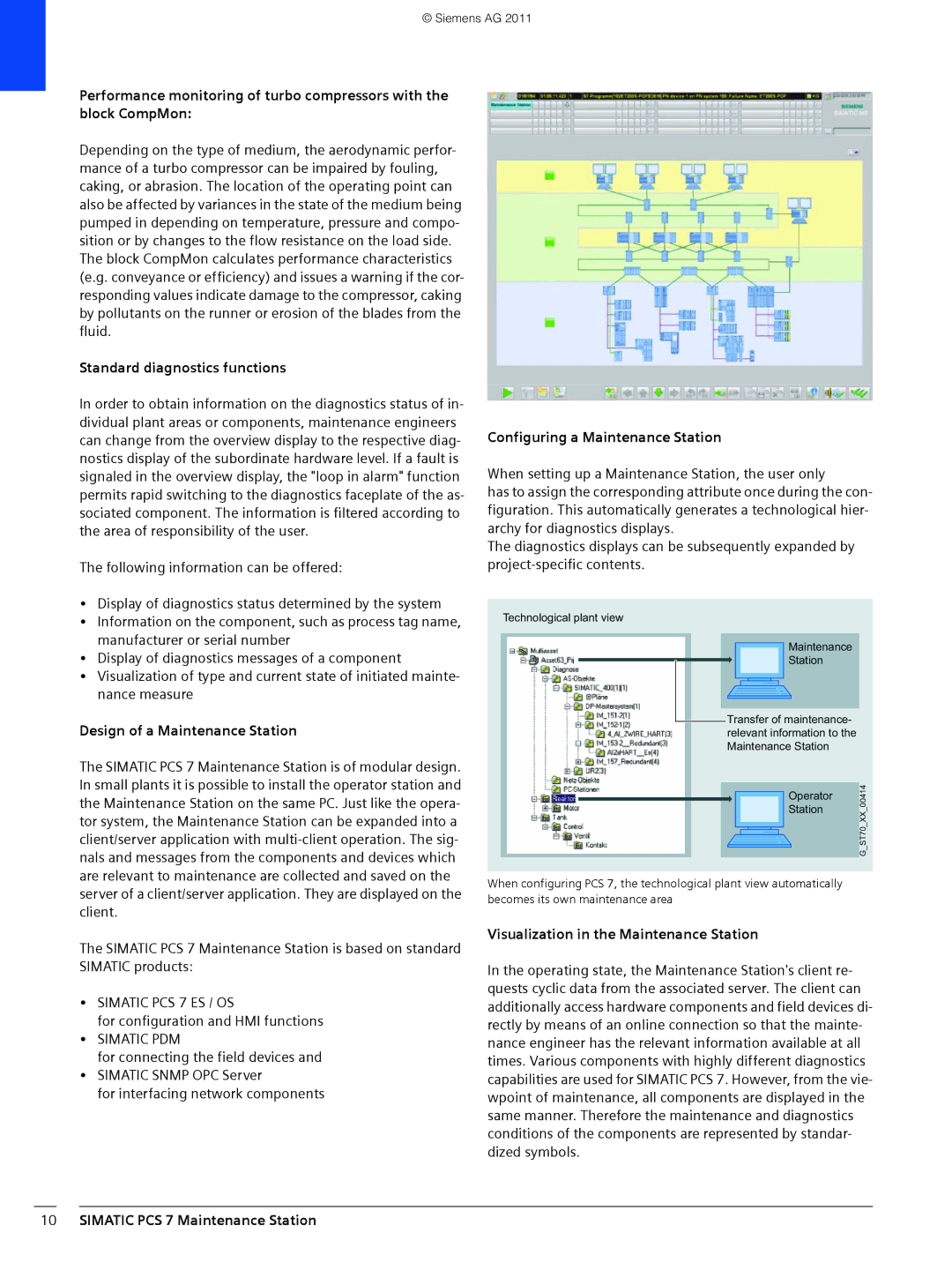

Configuring a Maintenance Station

When setting up a Maintenance Station, the user only

has to assign the corresponding attribute once during the con- figuration. This automatically generates a technological hier- archy for diagnostics displays.

The diagnostics displays can be subsequently expanded by

Technological plant view

Maintenance

Station

![]() Transfer of maintenance- relevant information to the Maintenance Station

Transfer of maintenance- relevant information to the Maintenance Station

|

|

|

|

|

| Operator | 00414 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

| Station | G ST70 XX | |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

When configuring PCS 7, the technological plant view automatically becomes its own maintenance area

Visualization in the Maintenance Station

In the operating state, the Maintenance Station's client re- quests cyclic data from the associated server. The client can additionally access hardware components and field devices di- rectly by means of an online connection so that the mainte- nance engineer has the relevant information available at all times. Various components with highly different diagnostics capabilities are used for SIMATIC PCS 7. However, from the vie- wpoint of maintenance, all components are displayed in the same manner. Therefore the maintenance and diagnostics conditions of the components are represented by standar- dized symbols.